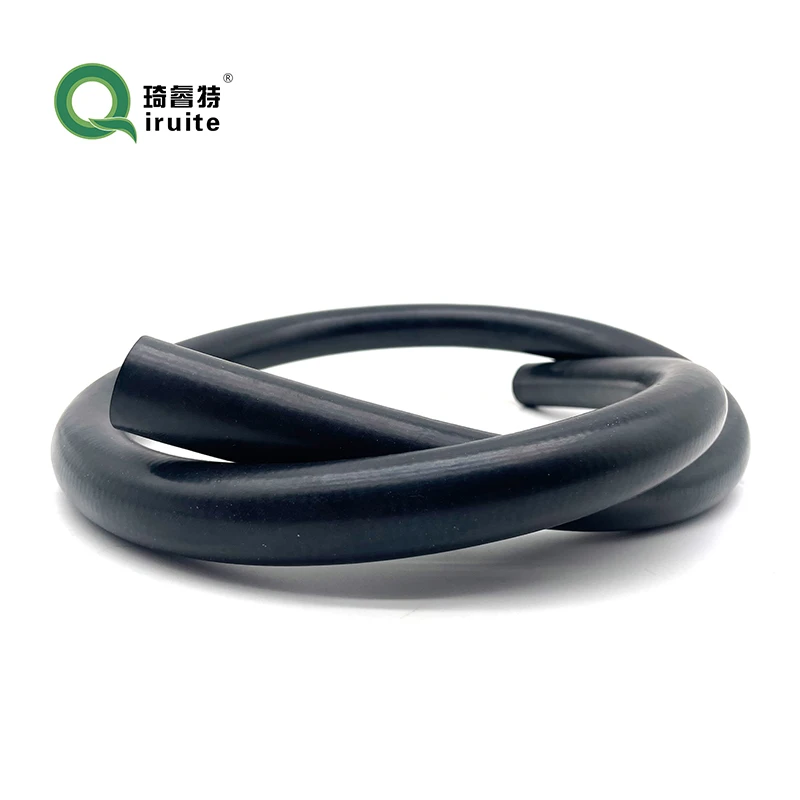

4 inch mechanical coupling

Understanding 4-Inch Mechanical Couplings Applications, Types, and Benefits

Mechanical couplings are essential components in various engineering and industrial applications, facilitating the connection of two shafts to transmit power and motion. Among the numerous types of couplings available, the 4-inch mechanical coupling stands out due to its versatility, durability, and efficiency. This article aims to provide a comprehensive overview of 4-inch mechanical couplings, their applications, types, and benefits.

What is a Mechanical Coupling?

A mechanical coupling is a device that connects two shafts to enable power transmission between them. Couplings are crucial in various machinery and equipment, such as motors, pumps, and generators. They help in the smooth operation of these machines by allowing for slight misalignments and reducing the effects of vibrations, which could lead to wear and tear over time.

Characteristics of 4-Inch Mechanical Couplings

The designation 4-inch in mechanical couplings typically refers to the outer diameter or the size of the coupling fitting. These couplings are particularly popular in industrial applications due to their ability to handle substantial loads while maintaining a compact design.

A 4-inch coupling can accommodate varied shaft sizes while providing robust torque transmission. They are made from a variety of materials such as steel, aluminum, and plastic, depending on the specific application requirements, such as strength, weight, and corrosion resistance.

Applications of 4-Inch Mechanical Couplings

4-inch mechanical couplings are utilized across a diverse range of industries. Here are some noteworthy applications

1. Pumping Systems Many pumping systems use 4-inch couplings to connect the pump motor to the impeller shaft, ensuring efficient transfer of power.

2. HVAC Systems In heating, ventilation, and air conditioning systems, these couplings help connect fans and blowers, ensuring the effective movement of air.

3. Conveyor Systems In manufacturing and material handling, 4-inch couplings connect various conveyor components, maintaining synchronization and proper operation.

4. Automotive Automotive applications often employ 4-inch couplings particularly in driveshafts and transmission systems, where sturdy connections are crucial for performance.

5. Agricultural Machinery Couplings in tractors and other agricultural equipment use 4-inch couplings for linking different machinery components, enabling efficient operation in the field.

4 inch mechanical coupling

Types of 4-Inch Mechanical Couplings

There are several types of 4-inch mechanical couplings, each designed to address specific needs

1. Rigid Couplings This type of coupling provides a solid connection between shafts, ensuring no relative motion occurs. Rigid couplings are ideal for applications where precise alignment is necessary.

2. Flexible Couplings These couplings can accommodate some misalignment between the shafts, which is vital in many dynamic applications. They help in minimizing stress on machinery caused by vibrations or movements.

3. Fluid Couplings Fluid couplings use a hydraulic fluid to transmit torque and provide a certain degree of speed control. They are commonly used in heavy machinery and vehicle drivetrains.

4. Slip Couplings Designed to allow limited axial movement, slip couplings are useful in applications where components may experience thermal expansion or contraction.

Benefits of Using 4-Inch Mechanical Couplings

1. Versatility The 4-inch size fits many industrial applications, making it a popular choice among engineers and designers.

2. Efficiency By minimizing the loss of power during transmission, these couplings enable machines to operate more efficiently.

3. Reduced Wear and Tear Flexible couplings mitigate the effects of misalignment and vibrations, leading to a longer lifespan for connected components.

4. Cost-Effectiveness With the right coupling, maintenance costs can be significantly lower, as wear-related failures are reduced.

5. Ease of Installation Many 4-inch mechanical couplings are designed for easy installation and removal, allowing for quick repairs and maintenance.

Conclusion

The 4-inch mechanical coupling plays a significant role in various industries by providing robust and reliable connections between shafts. With their versatility in applications and types, these couplings not only enhance the efficiency of machinery but also contribute to reduced maintenance costs and prolonged equipment lifespan. By understanding the characteristics and benefits of 4-inch couplings, engineers and technicians can make informed decisions that optimize their operational capabilities.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025