Jan . 31, 2025 05:56

Back to list

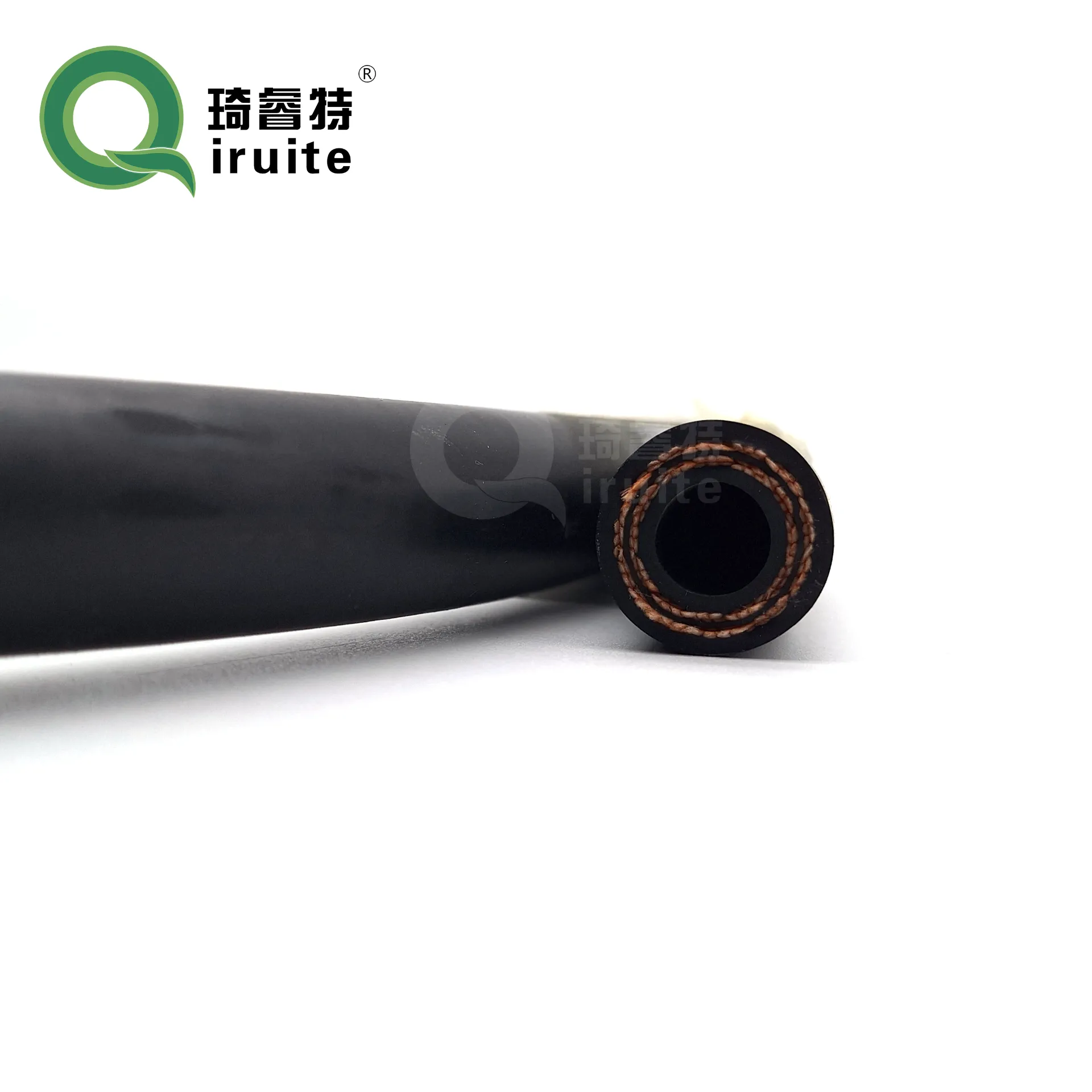

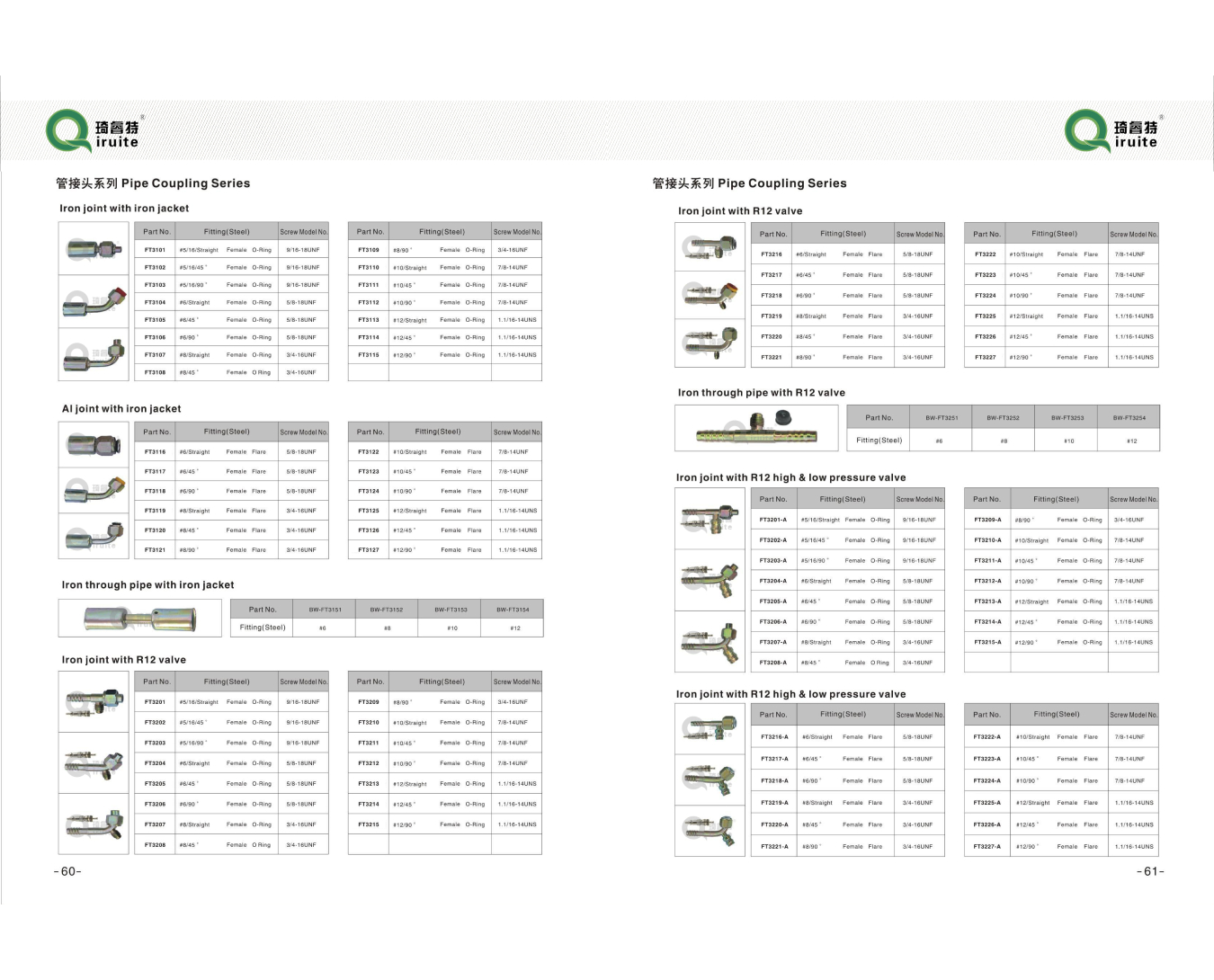

Pipe Coupling Type

The 15-inch culvert couplers are pivotal components in modern drainage systems, offering efficient solutions for joining various piping systems seamlessly. The primary purpose of these couplers is to ensure a fluid and debris-free connection that stands the test of time, environmental factors, and the demands of heavy infrastructure projects.

Authoritativeness in the realm of drainage solutions stems from the capacity to supply products backed by extensive research and field testing. Leading manufacturers often engage in exhaustive testing scenarios, simulating extreme environmental conditions and load-bearing capacities to perfect their products. This establishes a product line that contractors and civil engineers can rely on to deliver consistent results over the lifespan of the installation. In the field, real-world experiences further substantiate the efficacy of 15-inch culvert couplers. Case studies highlight successful deployments in diverse environments, ranging from volatile climates prone to freeze-thaw cycles to arid regions where temperature fluctuations are extreme. These couplers have proven their worth by maintaining a secure seal, preventing roadway water logging, and mitigating the risks associated with pipe misalignment and joint failure. Experts within the industry advocate for using these advanced couplers not only in new installations but also as upgrades for existing systems. The ease of integration and the improvement in performance attributes make them a wise investment for projects prioritizing long-term infrastructure resilience and operational efficiency. In conclusion, the 15-inch culvert coupler stands as a testament to modern engineering's capability to improve infrastructure reliability through innovative materials, rigorous testing, and adherence to authoritative standards. Their role in stormwater management cannot be overstated; by providing robust connections in piping systems, these couplers help safeguard our communities from flooding risks and maintain essential transportation networks. These aspects, when combined, establish the 15-inch culvert coupler as an indispensable component in contemporary civil engineering projects, underscoring the product's worth in addressing today's complex drainage challenges.

Authoritativeness in the realm of drainage solutions stems from the capacity to supply products backed by extensive research and field testing. Leading manufacturers often engage in exhaustive testing scenarios, simulating extreme environmental conditions and load-bearing capacities to perfect their products. This establishes a product line that contractors and civil engineers can rely on to deliver consistent results over the lifespan of the installation. In the field, real-world experiences further substantiate the efficacy of 15-inch culvert couplers. Case studies highlight successful deployments in diverse environments, ranging from volatile climates prone to freeze-thaw cycles to arid regions where temperature fluctuations are extreme. These couplers have proven their worth by maintaining a secure seal, preventing roadway water logging, and mitigating the risks associated with pipe misalignment and joint failure. Experts within the industry advocate for using these advanced couplers not only in new installations but also as upgrades for existing systems. The ease of integration and the improvement in performance attributes make them a wise investment for projects prioritizing long-term infrastructure resilience and operational efficiency. In conclusion, the 15-inch culvert coupler stands as a testament to modern engineering's capability to improve infrastructure reliability through innovative materials, rigorous testing, and adherence to authoritative standards. Their role in stormwater management cannot be overstated; by providing robust connections in piping systems, these couplers help safeguard our communities from flooding risks and maintain essential transportation networks. These aspects, when combined, establish the 15-inch culvert coupler as an indispensable component in contemporary civil engineering projects, underscoring the product's worth in addressing today's complex drainage challenges.

Next:

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025