Understanding the Essentials of 1% 201% 4% Pipe Coupling Specifications and Applications

Understanding 1%, 201%, 4% Pipe Coupling An Overview

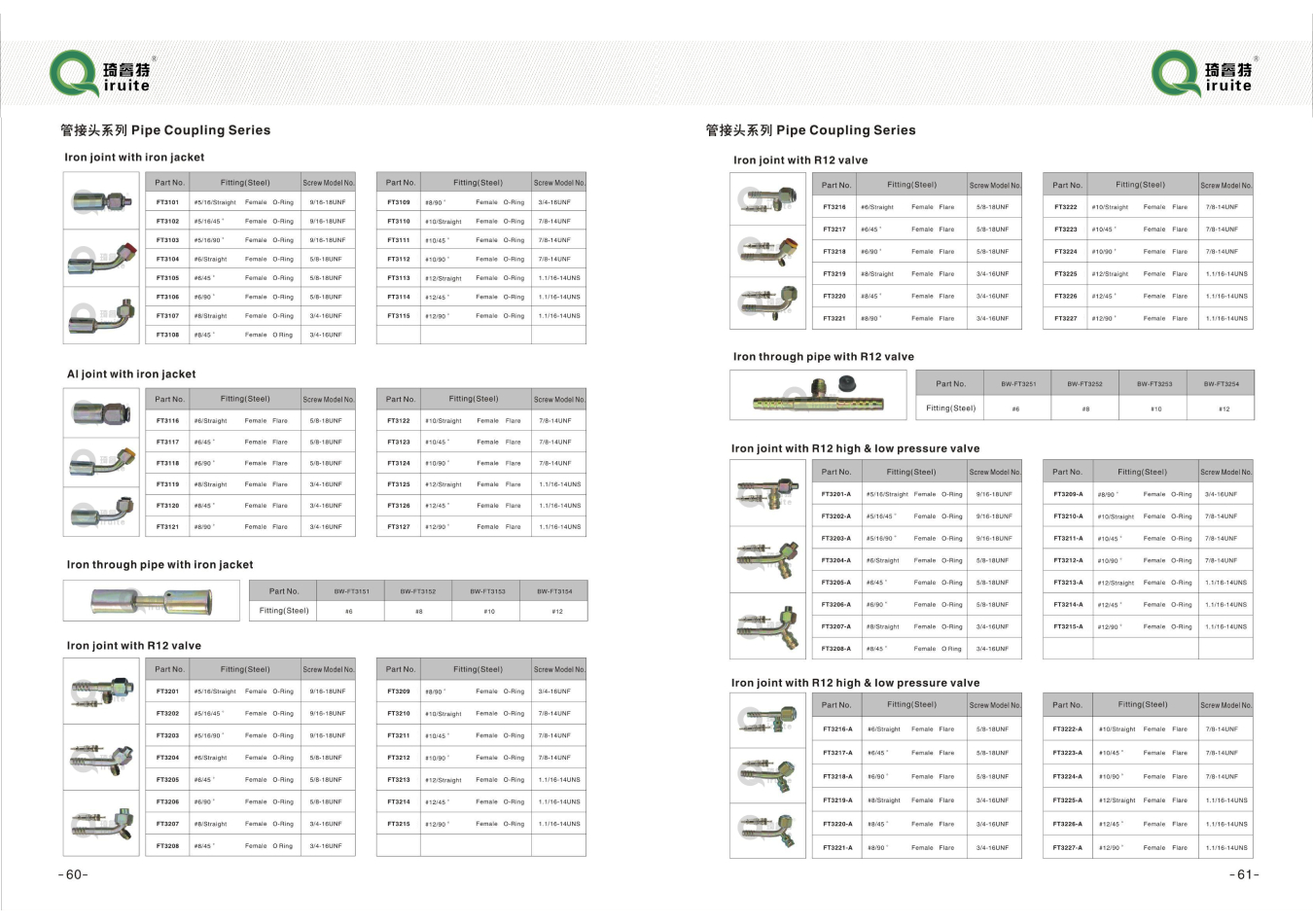

Pipe coupling is a fundamental component in various piping systems, used to connect multiple pipes and ensure the seamless transfer of fluids or gases. Among the various types of couplings available, those designed to handle specific percentages such as 1%, 201%, and 4% have unique applications and benefits that are crucial for engineers and designers to understand.

1% Pipe Coupling

A 1% pipe coupling typically denotes a coupling mechanism that is designed to handle pressures and stresses that are at a lower scale compared to its higher percentage counterparts. This type of coupling is commonly utilized in systems where the pressure fluctuations are minimal or where the medium being transported is not highly corrosive or volatile. They are often found in residential plumbing applications or simple irrigation systems, allowing for cost-effective and reliable connections without the need for high-end materials or designs.

201% Pipe Coupling

1 1 4 pipe coupling

On the other hand, a 201% pipe coupling indicates a high-performance coupling designed to manage significantly higher pressure conditions. This type of coupling is paramount in industrial applications where the pipes are subject to extreme conditions, including oil and gas transportation, chemical manufacturing, or even high-pressure steam systems. The materials used in the fabrication of 201% couplings are usually of high-grade steel or advanced alloys, ensuring durability and resistance against wear and tear. The enhanced design also incorporates safety features to prevent leakage and ensure the integrity of the entire piping system.

4% Pipe Coupling

Finally, the 4% pipe coupling represents a middle ground, handling moderate pressure conditions suitable for a variety of applications. Typical uses include water distribution systems, moderate chemical processing, and some HVAC systems. These couplings are designed to balance cost and performance, providing a reliable option for engineers working on projects where both dependability and budget considerations are critical. The 4% couplings often come with additional features such as anti-corrosion coatings to extend their lifespan in varying environmental conditions.

Conclusion

In conclusion, understanding the distinctions among 1%, 201%, and 4% pipe couplings is essential for selecting the right components for specific applications. Each type serves its unique purpose, offering varying levels of support and performance under different conditions. For engineers and designers, making informed choices about pipe coupling can lead to more efficient, safe, and cost-effective piping systems. Whether you're working on residential plumbing or high-pressure industrial projects, the right coupling is critical for success.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025