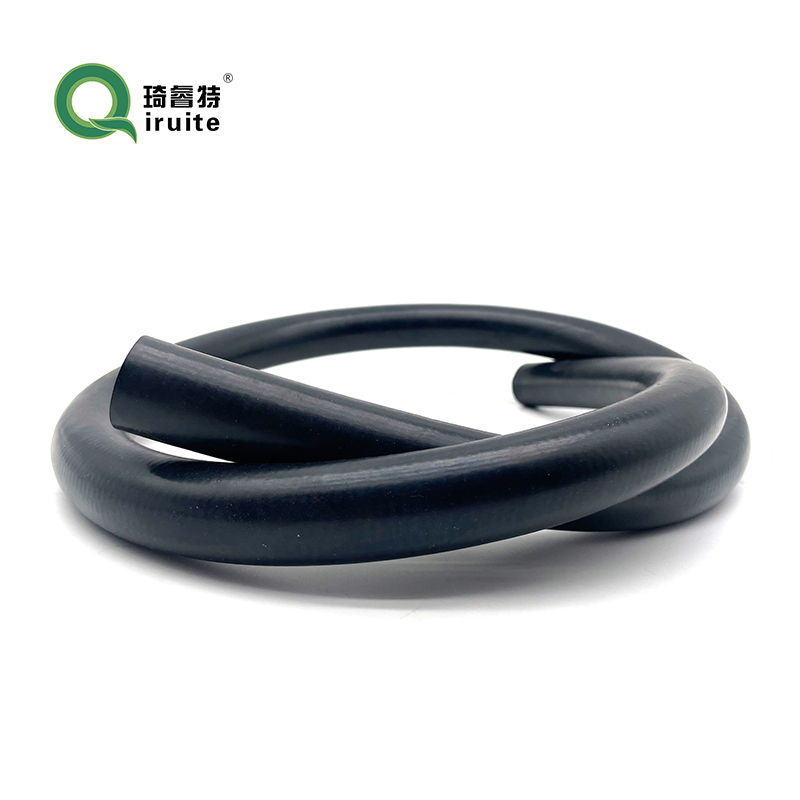

coupling in pipe fittings

Understanding Coupling in Pipe Fittings

In the world of plumbing and piping systems, couplings play a crucial role in connecting two lengths of pipe together. These fittings not only ensure a secure and leak-proof joint but also allow for adjustments in piping layout. As a fundamental component of fluid and gas transportation, the understanding of couplings is essential for engineers, plumbers, and DIY enthusiasts alike.

What Is a Coupling?

A coupling is a device used to join two pieces of pipe or tubing. It allows for the continuation of a pipeline by connecting two separate sections. Couplings can be made from various materials, including metal, plastic, and rubber, each offering different benefits depending on the application.

Types of Couplings

There are several types of couplings available in the market, each designed for specific applications

1. Slip Couplings A slip coupling slides over the ends of the two pipes being connected. This type is beneficial for making repairs without the need for welding or additional fittings.

2. Compression Couplings These fittings use a compressive force to join two pipes. They are particularly useful for joining pipes made of different materials and are often used in plumbing applications.

3. Welded Couplings Common in industrial settings, welded couplings require the ends of the pipes to be welded together, ensuring a strong and permanent joint.

4. Threaded Couplings These couplings use internal threads to connect two pipes. They are typically used in metal pipes and can be easily disassembled for maintenance.

5. Flanged Couplings Flanges are flat pieces of material that are bolted together, securely connecting the pipes. This type is often used in large piping systems where a strong and leak-proof connection is necessary.

6. Union Couplings Similar to threaded couplings, unions allow for easy disconnection of the pipes for maintenance or replacement.

The Importance of Coupling in Pipe Fittings

coupling in pipe fittings

The significant importance of couplings in pipe fittings lies in their ability to create a reliable, leak-proof connection. Couplings serve several critical functions in plumbing and piping systems

- System Integrity They maintain the integrity of the piping system by ensuring that fluid or gas flows seamlessly from one section to another without any loss of pressure or leakage.

- Flexibility and Adaptability Couplings enable modifications and adjustments to the pipeline. If changes in the layout are needed, couplings allow for quick disassembly and reassembly without extensive system downtime.

- Ease of Maintenance Many coupling types offer simple installation and removal processes, making maintenance tasks less labor-intensive. This is particularly important in commercial and industrial applications where time is money.

- Accommodating Expansion and Contraction Pipes can expand and contract due to temperature changes. Flexible couplings can absorb these movements, preventing stress on the piping system.

Choosing the Right Coupling

Selecting the appropriate coupling for a specific application is crucial for ensuring long-term performance and reliability. Factors to consider include

- Material Compatibility The coupling material must be compatible with the pipes being connected to prevent corrosion or reaction.

- Pressure and Temperature Ratings Couplings must be suited for the operating pressure and temperature of the system to avoid failure.

- Pipe Size Couplings are available in various sizes. It is essential to choose a coupling that matches the diameter of the pipes being joined.

- Installation Method Consideration of how the coupling will be installed—whether through welding, threading, or clamping—is vital for ensuring a secure connection.

Conclusion

Couplings are a vital component in the realm of pipe fittings, serving as the backbone of fluid and gas transportation systems. Understanding the types, importance, and selection criteria for couplings can lead to more efficient and reliable piping systems. Whether for residential plumbing or large-scale industrial applications, the right coupling can make all the difference in maintaining system integrity and functionality. In the ever-evolving field of plumbing and construction, staying informed about these essential fittings can enhance both new installations and ongoing maintenance, ensuring that systems operate smoothly for years to come.

-

Reliable Brake Line Solutions for Your VehicleNewsJun.05,2025

-

Quick Fix for Leaky Air Conditioning HosesNewsJun.05,2025

-

Powerful Sewer Jetting Solutions for Tough ClogsNewsJun.05,2025

-

Power Steering Hose Problems SolvedNewsJun.05,2025

-

Hose Protectors That Actually WorkNewsJun.05,2025

-

Essential Hose Connectors for Every HomeNewsJun.05,2025