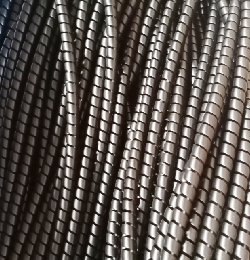

1 4 pipe coupling

The Significance of 1% 204% Pipe Coupling in Modern Engineering

In the diverse realm of engineering and construction, the importance of reliable connections cannot be overstated. Among the myriad of components that facilitate sturdy structures and efficient systems, the 1% 204% pipe coupling stands out for its unique specifications and applications. This article explores the significance of this specific type of pipe coupling, its uses, and how it contributes to the overall integrity of piping systems.

Understanding Pipe Couplings

Pipe couplings are essential fittings used to connect two sections of pipe, allowing for the extension of a pipeline or the joining of two separate lines. Depending on the application, couplings can be designed for various types of pipes, including those used in water supply, gas distribution, and industrial processes. Among the various couplings used, the 1% 204% pipe coupling is noted for its specialized design and material composition, making it suitable for both low-pressure and high-pressure applications.

Technical Specifications

The designation 1% 204% may refer to specific dimensions, pressure ratings, or material characteristics. Typically, numbers in such designations can indicate the pipe diameter, wall thickness, or even the percentage of a protective coating applied to enhance durability and resistance to corrosion. For example, a 1% coupling might imply a fitting that can withstand pressures up to 204 psi, indicating its capability for robust applications. These specifications ensure that the coupling can handle various operational conditions while maintaining integrity over time.

1 4 pipe coupling

Applications in Industry

1% 204% pipe couplings find applications across numerous industries. In the oil and gas sector, they are utilized to connect pipelines transporting hydrocarbon fluids. Their ability to withstand extreme conditions makes them ideal for such environments. In construction and infrastructure development, these couplings play a crucial role in the installation of water supply systems, sewage lines, and chemical transfer pipelines. Moreover, in agricultural applications, they facilitate irrigation systems, ensuring that water can be effectively and efficiently conveyed to crops.

Advantages of Using 1% 204% Pipe Couplings

One of the primary advantages of using 1% 204% pipe couplings is their reliability. Given the high demands of many industrial processes, these couplings provide secure connections that mitigate the risk of leaks or failures, which can result in costly downtime and repairs. Additionally, their material composition often includes corrosion-resistant features, making them suitable for harsh environments and contributing to a longer lifespan compared to standard couplings. This durability not only enhances safety but also reduces maintenance costs over the long term.

Conclusion

In conclusion, the 1% 204% pipe coupling represents a significant component in modern engineering and construction. Its specialized design caters to a variety of applications, ensuring that pipelines function optimally while maintaining safety and efficiency. As industries continue to evolve and demand more robust solutions, the role of advanced pipe couplings, such as the 1% 204%, will become increasingly vital. Understanding their characteristics and applications allows engineers and constructors to make informed decisions, ultimately driving the success of their projects.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025