air conditioning pipe sizes

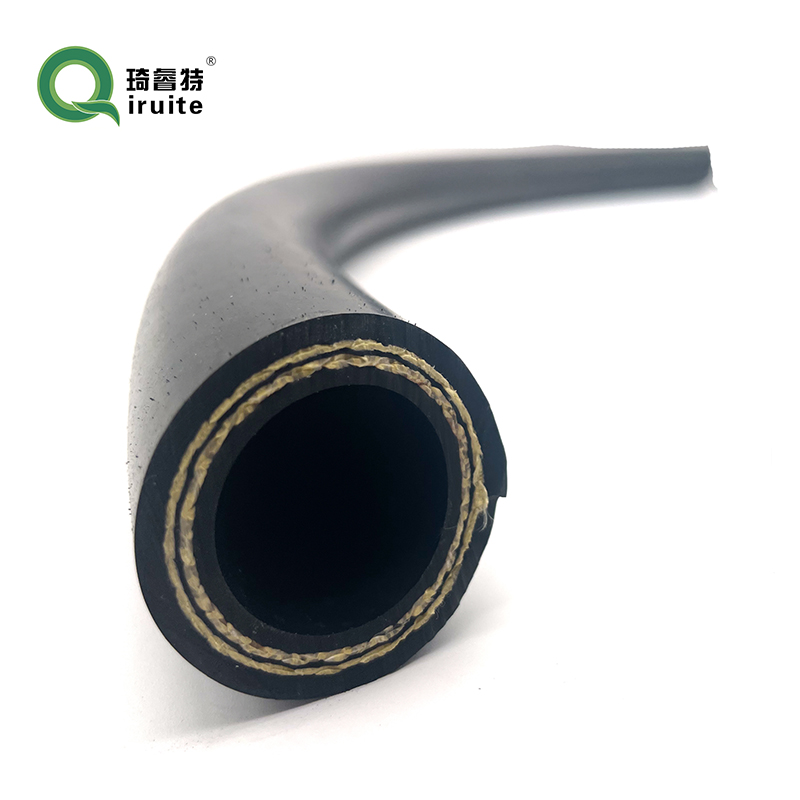

Selecting the appropriate air conditioning pipe size is crucial for ensuring an efficient and effective HVAC system

. Misjudging this aspect can lead to a range of issues, including suboptimal performance, increased energy consumption, and reduced system longevity. As an HVAC expert with years of field experience, I understand the importance of precision in choosing the right pipe dimensions.

When determining the ideal pipe size for an air conditioning system, engineers and technicians typically consider factors such as the type of refrigerant used, the system's overall capacity, and the distances involved in installation. The refrigerant type is particularly critical as it dictates the pressure and flow requirements. For instance, newer refrigerants like R-410A operate at higher pressures compared to older ones like R-22, affecting pipe size selection.

The system's capacity, measured in BTUs (British Thermal Units), also plays a significant role. Larger systems require larger diameter pipes to accommodate the increased volume of refrigerant needed to cool or heat a space efficiently. Conversely, smaller systems can function adequately with smaller pipes.

Distance is another key consideration. In installations where the condenser unit is located far from the indoor evaporator, larger diameter pipes may be necessary to minimize pressure drop along the length of the pipe, ensuring that refrigerant flow stays within optimal parameters. In contrast, shorter distances might allow for smaller pipes without sacrificing efficiency.

air conditioning pipe sizes

Additionally, minimizing friction is essential for maintaining system efficiency. This is where the expertise of an experienced technician becomes invaluable. Calculating the friction loss in pipes according to the specific layout and length of the piping run ensures the system operates smoothly. Miscalculations in this area could lead to compressor strain and energy loss, both of which are detrimental to the air conditioning unit's performance and longevity.

Using insulated copper piping is standard practice in the industry due to its superior thermal conductivity and resistance to corrosion. Proper insulation around the pipes prevents thermal loss or gain, which can significantly affect system efficiency, especially in extreme climates.

Furthermore, considering changes in temperature and ensuring that the installation adheres to the manufacturer’s specifications is vital for optimal performance. Manufacturers provide detailed guidelines and HVAC charts that outline suitable pipe sizes for various system capacities. Following these guidelines builds trust and reliability in the HVAC system's operation.

In conclusion, selecting the appropriate air conditioning pipe size is a complex process that goes beyond simply fitting components together. It involves a detailed understanding of the refrigerant properties, system capacity, distance, and material used. By following industry standards and leveraging the expertise of skilled professionals, it's possible to create an HVAC setup that is efficient, reliable, and long-lasting. Professionals who adhere to these practices not only advocate for best practices within the industry but also uphold a system of trust and quality that customers can rely on, ensuring their comfort and satisfaction with their air conditioning systems.

-

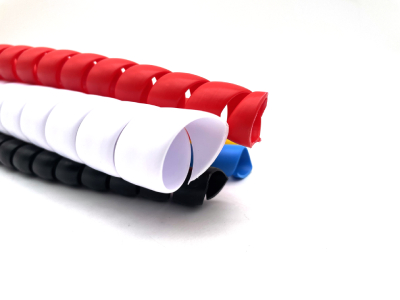

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025