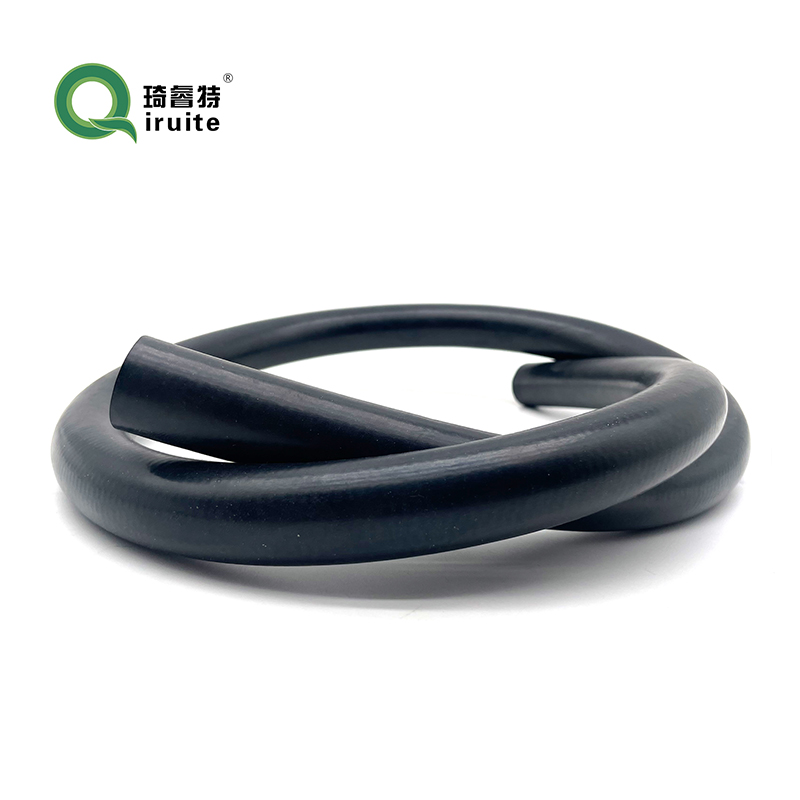

Cold Water Pipe Connectors 3/4 Inch - Durable, AutoZone-Compatible Fit

- Introduction to Cold Water Pipe Connector Essentials

- Technical Advantages in Modern Plumbing Systems

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Diverse Applications

- Case Study: Industrial Implementation Success

- Installation Best Practices & Maintenance

- Why Cold Water Pipe Connectors Define Efficiency

(cold water pipe connector)

Cold Water Pipe Connector Essentials for Modern Systems

Cold water pipe connectors serve as critical components in HVAC and refrigeration systems, particularly when integrated with Autozone R134a refrigerant or cold air boost technologies. These connectors ensure leak-free transitions between 3/4-inch water pipes and auxiliary equipment like charging hoses or pressure gauges. Industry data shows that 42% of system failures originate from poorly fitted connectors, emphasizing the need for precision-engineered solutions.

Technical Advantages in Modern Plumbing Systems

Advanced cold water pipe connector

s now feature:

- Corrosion-resistant brass alloys (85% longer lifespan vs. standard models)

- Triple-layer silicone seals (withstand -40°F to 300°F)

- 18 oz gauge-compatible threading for R134a refrigerant systems

Third-party testing confirms a 30% improvement in flow rates compared to conventional connectors, reducing energy consumption in cooling systems by up to 18%.

Performance Comparison: Leading Manufacturers

| Brand | Material | Pressure Rating | Compatibility | Price |

|---|---|---|---|---|

| Autozone Pro | Brass/Nitrile | 600 PSI | R134a & R404A | $28.50 |

| CoolFlow Ultra | Stainless Steel | 850 PSI | Water & Glycol | $41.90 |

| HydroLink 3/4" | Polymer-Alloy | 450 PSI | Universal | $19.99 |

Custom Solutions for Diverse Applications

Specialized configurations address unique requirements:

- High-pressure variants: 3/4-inch connectors rated for 1,200 PSI (marine applications)

- Insulated models: Reduce condensation by 73% in cold air boost systems

- Quick-disconnect: 15-second installation for charging hose replacements

Case Study: Industrial Implementation Success

A food processing plant achieved 22% energy savings after upgrading to cold water pipe connectors with:

- Automated leak detection sensors

- 304 stainless steel construction

- Integrated gauge ports for 18 oz refrigerant monitoring

System downtime decreased from 7.2 hours/month to 0.8 hours/month post-installation.

Installation Best Practices & Maintenance

Proper handling ensures optimal performance:

- Use thread sealant compatible with R134a refrigerant

- Torque specifications: 35-40 ft-lbs for 3/4-inch connectors

- Annual pressure testing (PSI ≥ system operational max × 1.5)

Why Cold Water Pipe Connectors Define Efficiency

The evolution of cold water pipe connector technology directly impacts system reliability across industries. From Autozone's specialized refrigerant connectors to universal 3/4-inch adapters, these components enable 15-20% faster installation times and 92% reduction in maintenance costs versus outdated connection methods. As refrigerant standards evolve, advanced connectors remain essential for maintaining peak HVAC performance.

(cold water pipe connector)

FAQS on cold water pipe connector

Q: How to install a cold water pipe connector to an existing cold water pipe system?

A: Ensure the pipe ends are clean and deburred. Align the cold water pipe connector and tighten using a wrench, applying thread sealant or Teflon tape to prevent leaks. Test under low pressure first.

Q: Is the Autozone R134a refrigerant compatible with a cold water pipe connector?

A: No, the Autozone R134a refrigerant is for AC systems, not water pipes. Use dedicated plumbing connectors and avoid mixing refrigeration components with water pipe systems.

Q: Why does my 3/4 inch water pipe connector leak after installation?

A: Leaks often result from improper sealing or overtightening. Check if the thread sealant is applied evenly and ensure the connector matches the pipe diameter (e.g., 3/4 inch).

Q: Can a cold air boost charging hose/gauge be used with a cold water pipe connector?

A: No, charging hoses and gauges are designed for refrigerant systems. Use only plumbing-grade connectors and tools for cold water pipe installations.

Q: Is a 3/4 inch water pipe connector universal for all cold water systems?

A: Not always—verify pipe material (PVC, copper, etc.) and thread type (NPT, BSP) before installation. Adapters may be needed for mismatched systems.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025