जुन . 25, 2024 19:35

Back to list

Exploring Threaded Pipe Couplings A Comprehensive Guide

The Ubiquitous Role of Pipe Couplings in Threaded Connections A Technical Perspective

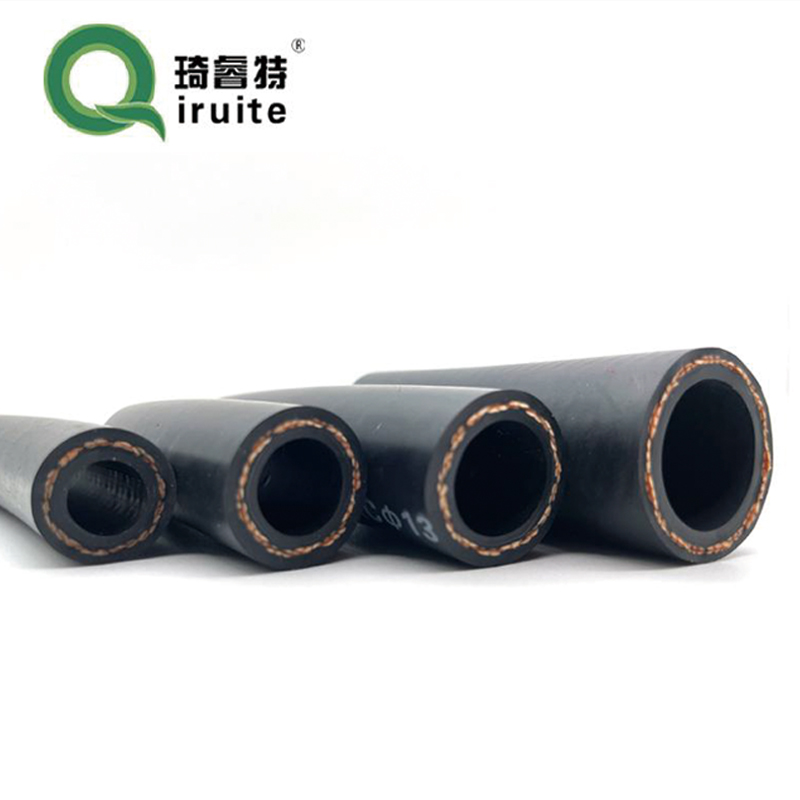

In the realm of industrial engineering and infrastructure, pipe couplings play a pivotal role in connecting and sealing pipes, ensuring fluid flow and maintaining structural integrity. The term pipe coupling, threaded refers to a critical component that bridges the gap between two pipes, allowing for the smooth transmission of liquids, gases, or compressed air, while accommodating temperature fluctuations and expansion.

Threaded pipe couplings are a popular choice due to their simplicity, versatility, and reliability. They rely on the interlocking helical threads, which provide a strong mechanical seal and a secure grip. These connections are often made from materials like steel, brass, or plastic, each selected based on the application's requirements, temperature resistance, and chemical compatibility.

The process of manufacturing a threaded pipe coupling involves precise threading, which ensures a snug fit when tightened. This is achieved through various methods, including cold forming, hot forging, or machining, depending on the material and desired strength. The threads are designed to follow international standards like ISO, ANSI, or ASME, ensuring consistent quality across different industries.

Installation of these couplings is typically quick and straightforward, as they do not require specialized tools or complex assembly procedures. However, proper torque application is crucial for preventing leaks and premature failure. Over-tightening can cause thread damage, while under-tightening may compromise the seal Over-tightening can cause thread damage, while under-tightening may compromise the seal Over-tightening can cause thread damage, while under-tightening may compromise the seal Over-tightening can cause thread damage, while under-tightening may compromise the seal

Over-tightening can cause thread damage, while under-tightening may compromise the seal Over-tightening can cause thread damage, while under-tightening may compromise the seal pipe coupling threaded.

Threaded pipe couplings come in various types, such as slip-on, compression, and socket-weld, each catering to specific needs. Slip-on couplings, also known as NPT (National Pipe Thread), are suitable for low-pressure applications, while compression couplings use an internal O-ring to seal against pressure. Socket-weld couplings, on the other hand, offer a higher level of integrity and are ideal for high-pressure systems.

Maintenance of threaded pipe couplings is relatively simple, with regular inspections for signs of wear, corrosion, or leaks being essential. Periodic tightening or replacement, as needed, ensures optimal performance and longevity.

In conclusion, pipe couplings, particularly those with threads, are indispensable elements in modern infrastructure. Their ability to join pipes efficiently, withstand varying conditions, and maintain reliability make them a cornerstone of numerous industrial processes. As technology advances and new materials emerge, the design and functionality of threaded pipe couplings will continue to evolve, ensuring that they remain a vital component in the seamless functioning of our interconnected world.

pipe coupling threaded.

Threaded pipe couplings come in various types, such as slip-on, compression, and socket-weld, each catering to specific needs. Slip-on couplings, also known as NPT (National Pipe Thread), are suitable for low-pressure applications, while compression couplings use an internal O-ring to seal against pressure. Socket-weld couplings, on the other hand, offer a higher level of integrity and are ideal for high-pressure systems.

Maintenance of threaded pipe couplings is relatively simple, with regular inspections for signs of wear, corrosion, or leaks being essential. Periodic tightening or replacement, as needed, ensures optimal performance and longevity.

In conclusion, pipe couplings, particularly those with threads, are indispensable elements in modern infrastructure. Their ability to join pipes efficiently, withstand varying conditions, and maintain reliability make them a cornerstone of numerous industrial processes. As technology advances and new materials emerge, the design and functionality of threaded pipe couplings will continue to evolve, ensuring that they remain a vital component in the seamless functioning of our interconnected world.

Over-tightening can cause thread damage, while under-tightening may compromise the seal Over-tightening can cause thread damage, while under-tightening may compromise the seal

Over-tightening can cause thread damage, while under-tightening may compromise the seal Over-tightening can cause thread damage, while under-tightening may compromise the seal pipe coupling threaded.

Threaded pipe couplings come in various types, such as slip-on, compression, and socket-weld, each catering to specific needs. Slip-on couplings, also known as NPT (National Pipe Thread), are suitable for low-pressure applications, while compression couplings use an internal O-ring to seal against pressure. Socket-weld couplings, on the other hand, offer a higher level of integrity and are ideal for high-pressure systems.

Maintenance of threaded pipe couplings is relatively simple, with regular inspections for signs of wear, corrosion, or leaks being essential. Periodic tightening or replacement, as needed, ensures optimal performance and longevity.

In conclusion, pipe couplings, particularly those with threads, are indispensable elements in modern infrastructure. Their ability to join pipes efficiently, withstand varying conditions, and maintain reliability make them a cornerstone of numerous industrial processes. As technology advances and new materials emerge, the design and functionality of threaded pipe couplings will continue to evolve, ensuring that they remain a vital component in the seamless functioning of our interconnected world.

pipe coupling threaded.

Threaded pipe couplings come in various types, such as slip-on, compression, and socket-weld, each catering to specific needs. Slip-on couplings, also known as NPT (National Pipe Thread), are suitable for low-pressure applications, while compression couplings use an internal O-ring to seal against pressure. Socket-weld couplings, on the other hand, offer a higher level of integrity and are ideal for high-pressure systems.

Maintenance of threaded pipe couplings is relatively simple, with regular inspections for signs of wear, corrosion, or leaks being essential. Periodic tightening or replacement, as needed, ensures optimal performance and longevity.

In conclusion, pipe couplings, particularly those with threads, are indispensable elements in modern infrastructure. Their ability to join pipes efficiently, withstand varying conditions, and maintain reliability make them a cornerstone of numerous industrial processes. As technology advances and new materials emerge, the design and functionality of threaded pipe couplings will continue to evolve, ensuring that they remain a vital component in the seamless functioning of our interconnected world. Latest news

-

Reliable Brake Line Solutions for Your VehicleNewsJun.05,2025

-

Quick Fix for Leaky Air Conditioning HosesNewsJun.05,2025

-

Powerful Sewer Jetting Solutions for Tough ClogsNewsJun.05,2025

-

Power Steering Hose Problems SolvedNewsJun.05,2025

-

Hose Protectors That Actually WorkNewsJun.05,2025

-

Essential Hose Connectors for Every HomeNewsJun.05,2025