air pipe coupling

Understanding Air Pipe Couplings An Essential Component in Fluid Systems

Air pipe couplings are critical components used in various fluid systems to connect pipes and facilitate the transportation of air and other gases. These couplings provide a secure and leak-free connection, ensuring the efficient flow of air in industrial, commercial, and residential applications. This article explores the design, types, applications, and importance of air pipe couplings in contemporary engineering systems.

What are Air Pipe Couplings?

Air pipe couplings are fittings that join two segments of piping or tubing, allowing for the flow of air while maintaining the structural integrity of the system. They come in various shapes and sizes, suited for different pipe diameters and pressure ratings. Couplings play an integral role in creating a seamless transition between pipe sections in systems ranging from simple home HVAC setups to complex industrial pneumatic systems.

Types of Air Pipe Couplings

1. Threaded Couplings These couplings are designed with internal threads that allow two pipes to be screwed together. They are widely used due to their ease of installation and ability to create a robust seal.

2. Slip-on Couplings Slip-on couplings are slid over the ends of two pipes and can be welded or clamped in place. Their design makes them suitable for quick installations, particularly in temporary setups.

3. Flanged Couplings Flanged couplings feature flat surfaces with bolt holes that join two pipe ends with flanges. This type is prevalent in larger pipe systems as it can handle high pressure and provides easy access for maintenance.

4. Compression Couplings These couplings use mechanical force to secure the connection. They are particularly effective for connecting pipes made from different materials, ensuring a leak-proof seal.

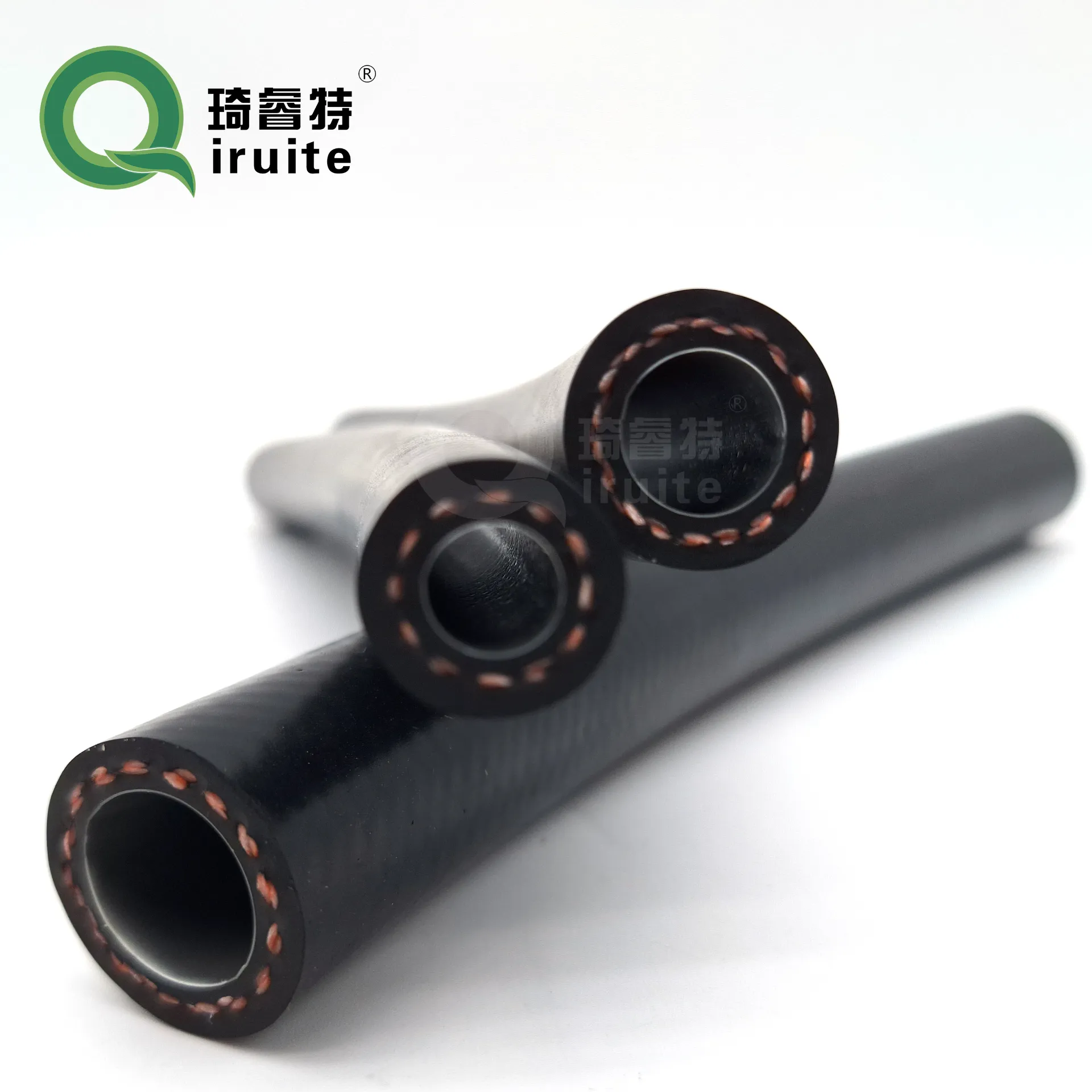

5. Flexible Couplings Designed to accommodate misalignment between pipes, flexible couplings are made from materials like rubber or elastomers, allowing for slight movements without compromising the integrity of the system.

air pipe coupling

Applications of Air Pipe Couplings

Air pipe couplings find extensive use in numerous sectors

- HVAC Systems In heating, ventilation, and air conditioning systems, couplings ensure proper airflow and efficiency. They connect ducts, enabling the smooth transportation of conditioned air throughout a building.

- Industrial Pneumatic Systems Many manufacturing processes involve pneumatic tools that rely on pressurized air. Couplings in these systems are crucial for connecting air hoses and ensuring consistent air delivery to pneumatic machinery.

- Compressed Air Applications Couplings are often utilized in various compressed air setups, such as air compressors and pneumatic lines, helping to manage pressure and flow rates effectively.

- Automotive and Aerospace In automotive applications, air pipe couplings are used in brake systems, fuel delivery, and exhaust setups, where secure connections are paramount for safety and performance.

Importance of Quality in Air Pipe Couplings

The choice of air pipe couplings can significantly impact the efficiency and reliability of fluid systems. High-quality couplings can withstand temperature fluctuations, pressure variations, and corrosive environments, ensuring longevity and reducing maintenance costs. Engineers must carefully consider materials, designs, and compatibility with existing systems when selecting couplings for their applications.

Conclusion

Air pipe couplings are vital components in various fluid systems, facilitating the efficient flow of air and other gases. Their diverse types and applications make them indispensable in modern engineering. By ensuring secure, leak-proof connections, air pipe couplings contribute to the overall performance and reliability of systems in numerous industries. As technology advances and the demand for efficient fluid transportation continues to grow, the importance of quality air pipe couplings will remain a pivotal focus for engineers and manufacturers alike. Investing in high-quality couplings is not just a matter of compliance but a strategic choice that can lead to improved operational efficiency and reduced long-term costs.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025