Creating High-Performance Power Steering Hoses for Improved Vehicle Handling and Durability

Making Power Steering Hoses A Comprehensive Guide

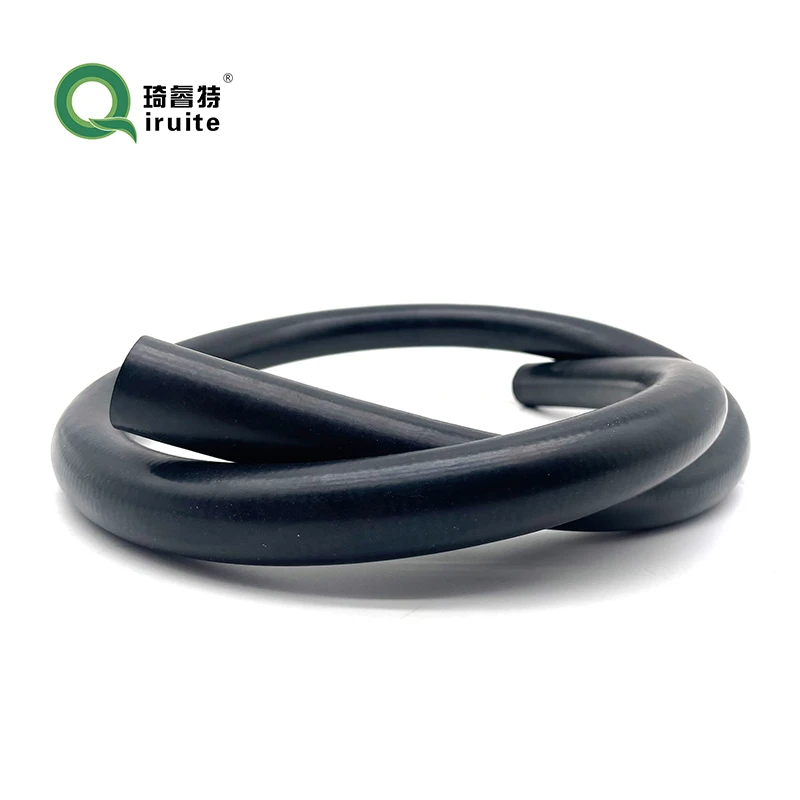

Power steering is a crucial component of modern vehicles, enhancing driver control and comfort. One of the essential parts of this system is the power steering hose, responsible for transferring hydraulic fluid between the power steering pump and the steering gear. In this article, we’ll explore the process of making power steering hoses, highlighting the materials, methods, and best practices involved in producing these vital automotive components.

Understanding Power Steering Hoses

Power steering hoses come in two main types high-pressure hoses and return hoses. High-pressure hoses connect the power steering pump to the steering gear, carrying fluid at a significant pressure, typically between 1,000 to 2,500 psi. Conversely, return hoses transport fluid back from the steering gear to the reservoir at lower pressures. The hoses must be resilient, flexible, and capable of withstanding extreme temperatures and pressures.

Materials Used in Power Steering Hoses

The production of power steering hoses involves the selection of appropriate materials, which are crucial for durability and performance. The most common materials include

1. Rubber Synthetic rubber is often used to produce the inner and outer layers of the hose due to its excellent flexibility and resistance to oils and heat.

2. Reinforcement To withstand high pressures, hoses typically incorporate reinforcement materials such as steel or textile braiding. This provides structural integrity and prevents bursting under pressure.

3. Fittings Metal fittings, usually made of aluminum or steel, are attached to the ends of the hoses for secure connections. These fittings must also be resistant to corrosion and wear.

The Manufacturing Process

The manufacturing of power steering hoses involves several key steps

1. Design and Specification The process begins with designing the hose according to the specifications required by the vehicle manufacturers. This includes determining the hose diameter, length, material composition, and pressure ratings.

2. Material Preparation The raw materials, including rubber sheets and reinforcing fibers, are prepared. Rubber is often mixed with additives to enhance its properties, such as resistance to wear and expansion.

making power steering hoses

3. Extrusion The inner tube is typically extruded using a specialized machine that shapes the rubber into the desired diameter. This step is critical, as any inconsistencies in thickness can affect performance.

4. Reinforcement Application After the inner layer is formed, the reinforcement is applied. This can involve wrapping layers of steel or textile mesh around the hose to increase its strength.

5. Outer Layer Application The outer layer of rubber is then extruded over the reinforced core. This layer protects the internal structure from environmental factors such as heat, abrasion, and chemical exposure.

6. Curing Once assembled, hoses undergo a curing (vulcanization) process in which heat and pressure are applied. This step is vital as it solidifies the rubber, enhancing its durability and flexibility.

7. Fitting Attachment After curing, metal fittings are attached to both ends of the hose. This is done using crimping machines, which ensure a secure and leak-proof connection.

8. Testing The final step in production is rigorous testing. Hoses are subjected to high-pressure and temperature tests to ensure they meet the required safety and performance standards. Any defective hoses are discarded, while those that pass inspection are prepared for shipment.

Best Practices

To ensure the highest quality of power steering hoses, manufacturers should adhere to several best practices

- Quality Control Regular inspections and testing throughout the manufacturing process help maintain quality standards.

- Material Selection Using high-grade materials increases the durability and reliability of the hoses.

- Technological Advancements Investing in modern manufacturing technologies, such as automation and precision machinery, can improve efficiency and product quality.

Conclusion

The manufacturing of power steering hoses plays a vital role in ensuring the reliability and safety of vehicle steering systems. By understanding the materials, processes, and best practices involved, manufacturers can produce hoses that meet the stringent demands of modern automotive engineering. As vehicles continue to evolve, the importance of high-quality power steering hoses remains paramount for enhancing driver experience and safety.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025