Plain End Pipe Connector for Secure and Efficient Piping Solutions

Understanding Plain End Pipe Couplings A Comprehensive Overview

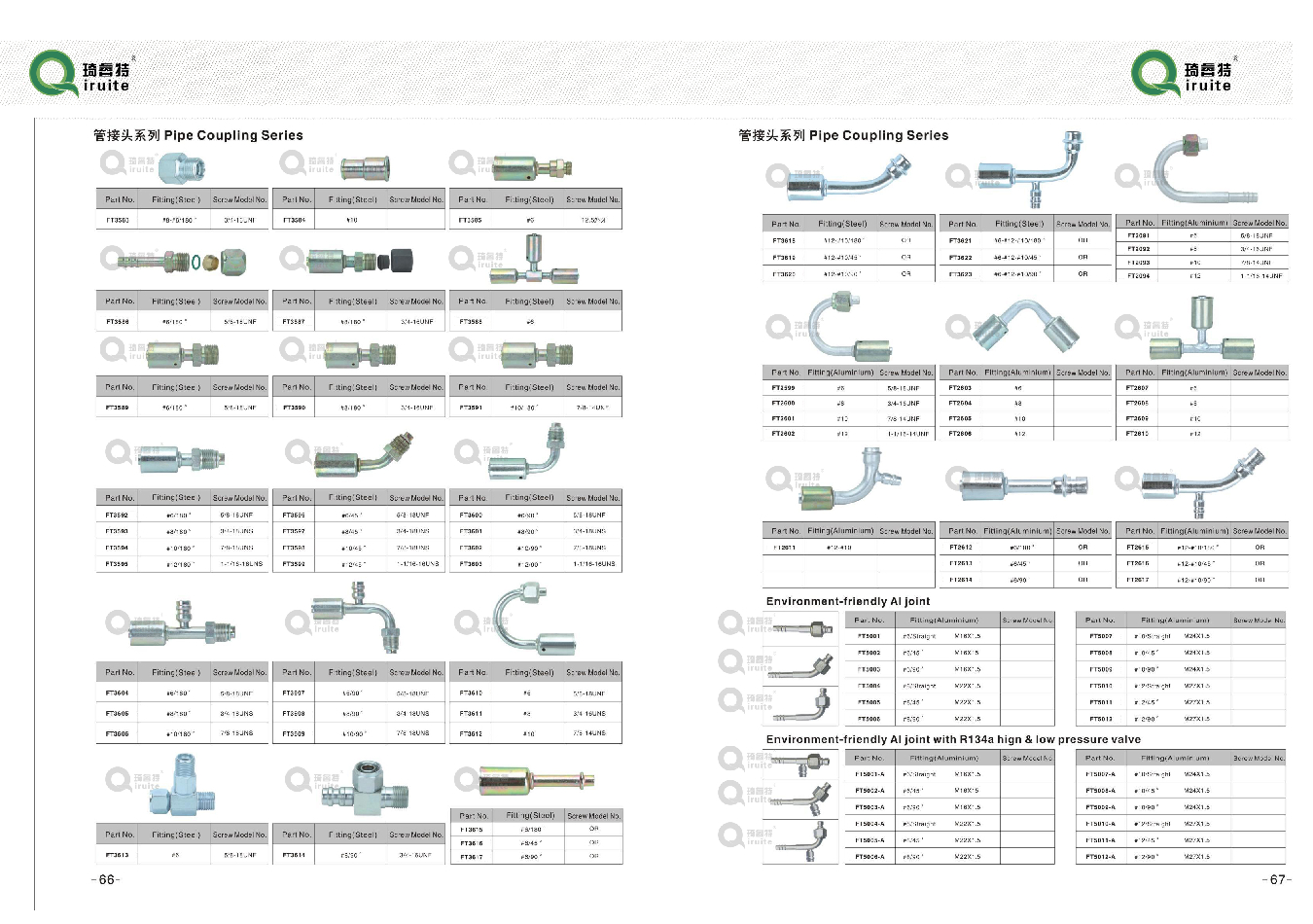

Plain end pipe couplings are pivotal components in the world of piping and plumbing. These fittings serve as essential links between two pipe sections, allowing for seamless flow of fluids and gases through various piping systems. Their simplicity and effectiveness make them widely used in a variety of industries, including construction, manufacturing, oil and gas, and water supply systems.

What is a Plain End Pipe Coupling?

A plain end pipe coupling is a device that connects two pipes with plain, or unthreaded, ends. This design is straightforward yet highly effective for several applications, especially where simple and reliable connections are necessary. These couplings can be manufactured from a wide array of materials, including metals such as steel, stainless steel, and aluminum, as well as plastics like PVC and polyethylene. Each material choice caters to different environmental conditions and requirements, such as corrosion resistance, temperature tolerance, and pressure considerations.

Types of Plain End Pipe Couplings

There are several types of plain end pipe couplings, each designed to meet specific needs

1. Sleeve Couplings These are straightforward cylindrical devices that slide over the ends of two pipes. Once in place, they are usually secured using welding, screws, or other fastening methods.

2. Reducer Couplings Designed to connect pipes of different diameters, reducer couplings facilitate the transition from a larger pipe to a smaller one. This is especially useful in systems where fluid flow needs to be controlled or varied.

3. Expansion Couplings These are used to accommodate thermal expansion in piping systems. They allow for slight movements due to temperature changes without compromising the connection or structural integrity.

4. Flexible Couplings While essentially plain end couplings, flexible couplings provide additional movement capabilities. They can absorb vibrations and misalignments, making them ideal for dynamic environments.

Advantages of Plain End Pipe Couplings

plain end pipe coupling

Plain end pipe couplings come with numerous advantages, making them a popular choice in the industry

1. Ease of Installation The design of plain end couplings allows for rapid installation. There are no threads to align or complex fittings to manage, which simplifies the construction process.

2. Versatility Because of their wide range of compatible materials, these couplings can be used in various applications, from residential plumbing to industrial piping systems.

3. Cost-effective The simplicity of plain end couplings often translates into lower manufacturing and installation costs. This affordability makes them an attractive option for many construction projects.

4. Reliability When properly installed, plain end pipe couplings provide a robust and leak-free connection. Their use in critical systems, like water supply and gas distribution, emphasizes their reliability.

Installation and Maintenance

The installation of plain end pipe couplings typically involves ensuring that the pipe ends are clean and free from debris. The coupling is then placed over the ends and secured according to the manufacturer’s guidelines. Depending on the type of coupling and the materials involved, this may involve welding, clamping, or using adhesive.

Regular inspection and maintenance are crucial for ensuring the longevity and performance of pipe coupling systems. Checking for signs of wear, corrosion, and leaks can prevent larger issues in the future. Proper maintenance schedules can help in timely repairs and replacements, thus ensuring continuous operation without costly downtimes.

Conclusion

Plain end pipe couplings are essential components in numerous piping systems across different industries. Their simplicity, ease of installation, and reliability have made them a preferred choice for many engineers and contractors. As technology advances, the materials and designs of these couplings will continue to evolve, offering even greater performance and versatility. Understanding the different types of couplings, their advantages, and maintenance requirements is vital for anyone involved in construction, plumbing, or piping management.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025