spiral guard hose protection

The Importance of Spiral Guard Hose Protection

In many industries, the efficient operation of machinery and equipment is crucial for productivity and safety. One often-overlooked aspect of this efficiency is the protection of hoses, which are vital components in various systems, including hydraulic, pneumatic, and fluid transfer applications. Among the available protective solutions, spiral guard hose protection has emerged as a favored choice due to its effectiveness and versatility.

Understanding Spiral Guard Hose Protection

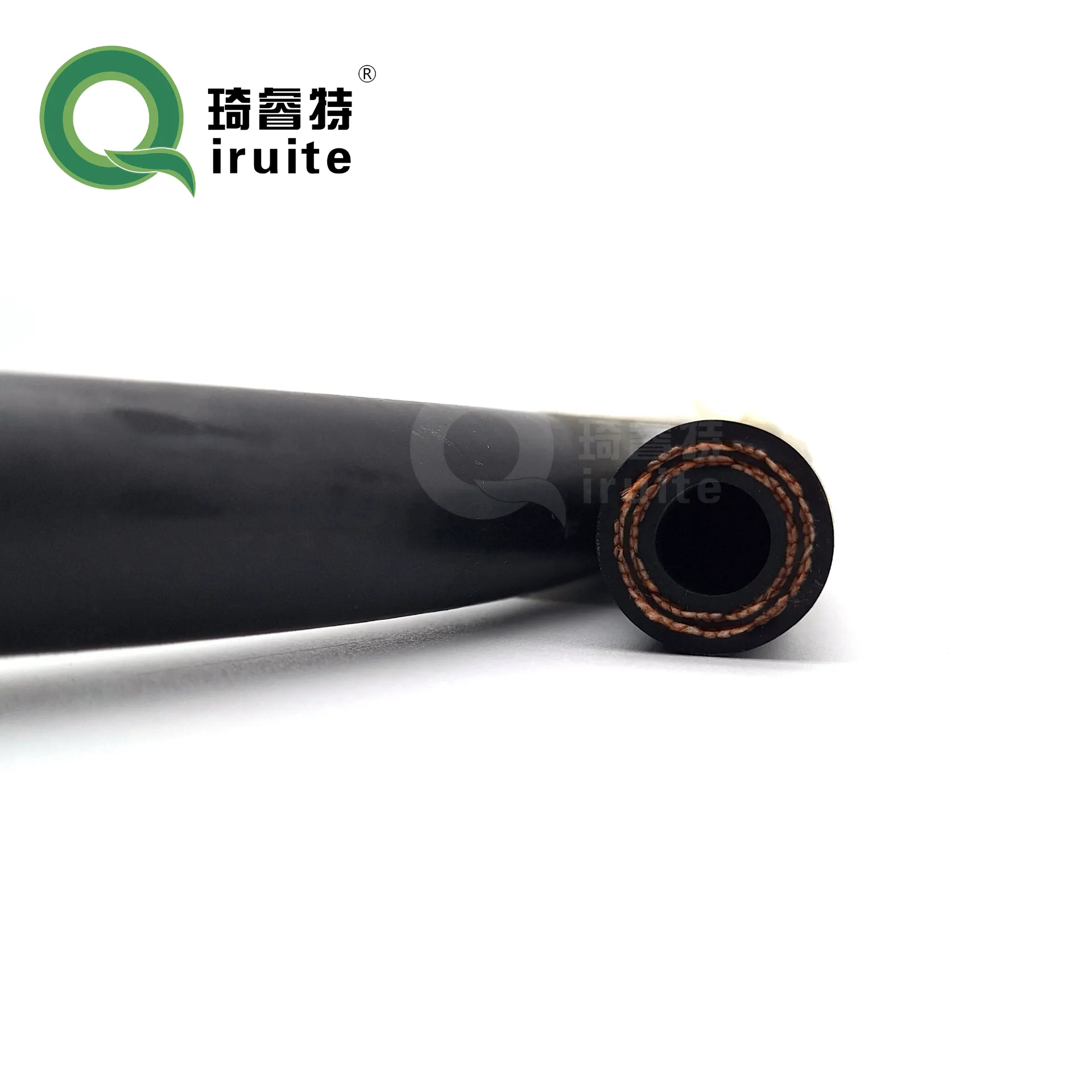

Spiral guard hose protection consists of a durable, spiral-shaped sleeve that wraps around hoses to shield them from abrasion, impacts, and environmental factors. Made from materials like polyethylene or nylon, these protective sleeves are designed for resilience, ensuring they can withstand the rigors of industrial settings. The spiral design allows for easy installation and flexibility, accommodating different hose sizes and configurations.

Key Benefits

1. Enhanced Abrasion Resistance One of the primary advantages of using spiral guard hose protection is its ability to protect hoses from abrasions caused by contact with other surfaces, machinery, or materials. Over time, these abrasions can lead to leaks, ruptures, and ultimately failure of the hose, resulting in costly downtime and repairs. The spiral guard effectively acts as a barrier, extending the life of the hose considerably.

2. Impact Protection Hoses are often subject to various impacts in busy work environments. Spiral guards provide a cushioning layer, minimizing the risk of damage from falling objects or sudden impacts. This added protection is particularly beneficial in manufacturing plants, construction sites, and other hazardous areas.

3. Environmental Protection In outdoor or harsh environments, hoses may be exposed to UV rays, chemicals, and extreme temperatures. Spiral guard hose protection helps insulate hoses from these detrimental factors, thereby maintaining their integrity and functionality over time. This is crucial for industries that rely on consistent performance, such as agriculture and oil and gas.

spiral guard hose protection

4. Improved Safety Leaking or ruptured hoses can pose significant safety risks to workers and operations. By employing spiral guard hose protection, companies can reduce the likelihood of hose failures, thereby enhancing workplace safety. This proactive measure can help prevent accidents that may arise from hose malfunctions, thus safeguarding personnel and equipment alike.

5. Aesthetic Appeal In addition to practical benefits, spiral guard hose protection can improve the aesthetic appearance of machinery and work areas. Color options allow for customization, enabling businesses to maintain a professional look while ensuring functional safety.

Easy Installation and Versatility

One of the most appealing aspects of spiral guard hose protection is its user-friendly installation process. The flexible, spiral design allows it to be easily applied to existing hoses without the need for special tools or equipment. Additionally, these protective sleeves can be cut to length, making them suitable for a vast range of applications.

This versatility extends beyond just hoses; spiral guards can be used in various settings, from automotive workshops to agriculture. Their adaptability means they can accommodate diverse hose types, diameters, and lengths, making them a valuable addition to any industrial toolkit.

Conclusion

Spiral guard hose protection is an essential investment for any operation that relies on hoses in their processes. By providing robust protection against abrasion, impact, environmental factors, and potential safety hazards, these guards help prolong the life of hoses and ensure operational efficiency. Moreover, their ease of installation and adaptability makes them an ideal choice for various applications. In today's fast-paced industrial world, prioritizing hose protection is not just a smart decision—it's a necessary one for maintaining safety, performance, and productivity.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025