ഫെബ്രു . 10, 2025 11:10

Back to list

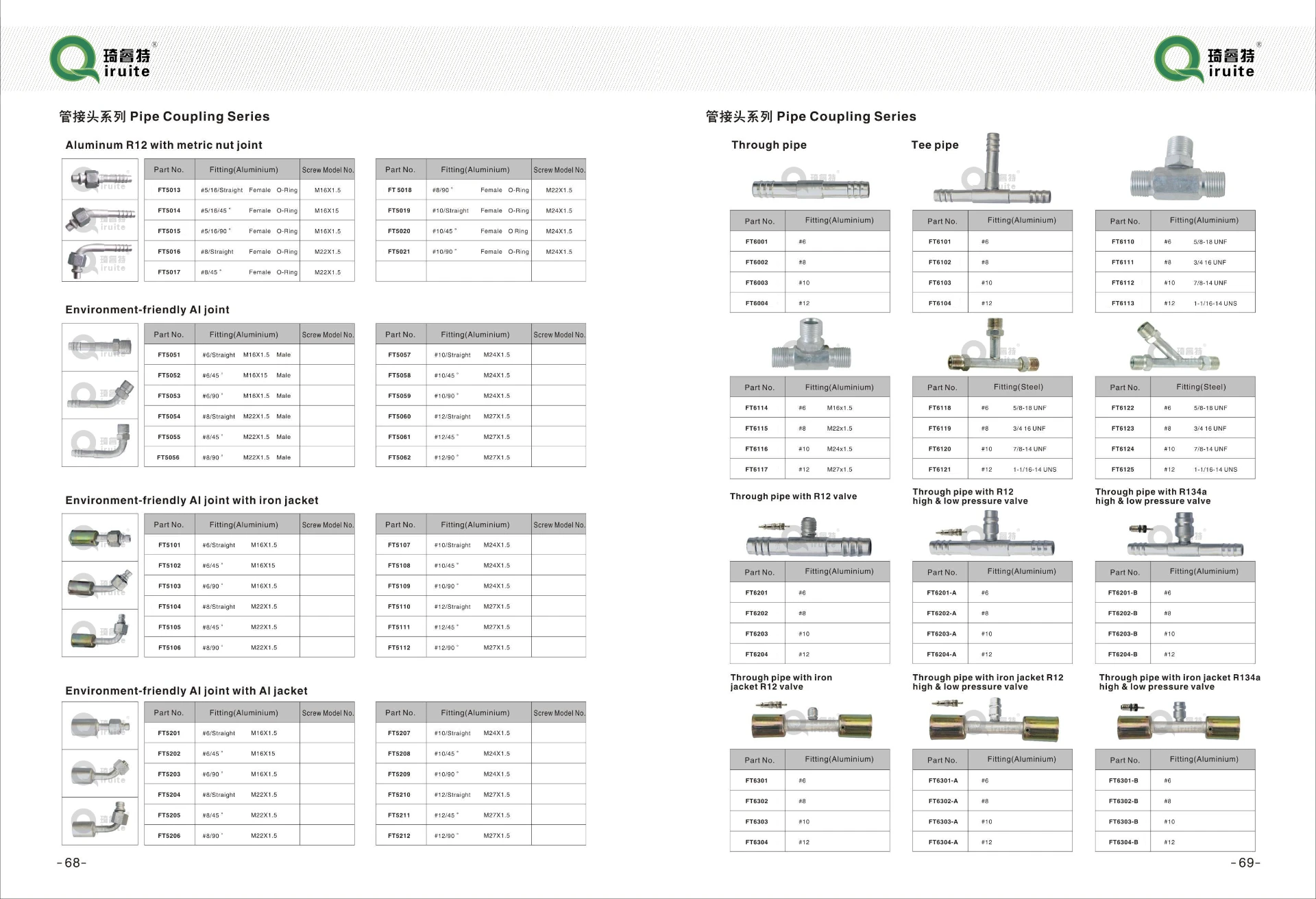

pipe connector price

Pipe connectors, often overlooked yet essential components of plumbing and industrial projects, play a crucial role in ensuring seamless connectivity within piping systems. The quest for the right pipe connector, while seeking optimum prices, involves understanding the factors influencing cost and their impact on the project's overall efficiency and safety.

Expertise in leveraging technology and market trends can also yield cost benefits. Adopting CAD software facilitates precise measurement and compatibility assessments, reducing waste and errors during installation. Furthermore, staying abreast of market trends can unveil opportunities to procure connectors in bulk or during promotional periods, offering substantial financial savings. Trustworthiness in the selection of pipe connectors is fortified through partnerships with reputable manufacturers and suppliers. Engaging with well-established brands known for quality and service excellence assures the procurement of authentic parts, free from defects, and backed by warranties. Such collaborations enhance project credibility and secure the integrity of piping systems, a non-negotiable in safeguarding both human and environmental safety. Furthermore, user and industry reviews offer valuable insights, revealing practical experiences that can guide purchasing decisions. Peer experiences shed light on the real-world performance of connectors, their resilience in diverse conditions, and the support offered by manufacturers, thereby reducing the uncertainty typically associated with new acquisitions. In conclusion, while the initial financial outlay for pipe connectors can vary widely, a holistic approach considering the interplay of material selection, design complexity, manufacturing standards, and supplier reliability can streamline costs effectively. Prioritizing long-term value over short-term savings not only enhances project efficiency but also fortifies the foundation of trust and safety, essential for any structural endeavor. By embracing an informed, strategic approach to purchasing pipe connectors, one can adeptly navigate the balance between cost and quality, ensuring robust and reliable piping networks.

Expertise in leveraging technology and market trends can also yield cost benefits. Adopting CAD software facilitates precise measurement and compatibility assessments, reducing waste and errors during installation. Furthermore, staying abreast of market trends can unveil opportunities to procure connectors in bulk or during promotional periods, offering substantial financial savings. Trustworthiness in the selection of pipe connectors is fortified through partnerships with reputable manufacturers and suppliers. Engaging with well-established brands known for quality and service excellence assures the procurement of authentic parts, free from defects, and backed by warranties. Such collaborations enhance project credibility and secure the integrity of piping systems, a non-negotiable in safeguarding both human and environmental safety. Furthermore, user and industry reviews offer valuable insights, revealing practical experiences that can guide purchasing decisions. Peer experiences shed light on the real-world performance of connectors, their resilience in diverse conditions, and the support offered by manufacturers, thereby reducing the uncertainty typically associated with new acquisitions. In conclusion, while the initial financial outlay for pipe connectors can vary widely, a holistic approach considering the interplay of material selection, design complexity, manufacturing standards, and supplier reliability can streamline costs effectively. Prioritizing long-term value over short-term savings not only enhances project efficiency but also fortifies the foundation of trust and safety, essential for any structural endeavor. By embracing an informed, strategic approach to purchasing pipe connectors, one can adeptly navigate the balance between cost and quality, ensuring robust and reliable piping networks.

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025