6 Inch Threaded Pipe Connector for Heavy-Duty Plumbing Applications and Installations

Understanding 6-Inch Threaded Pipe Couplings A Comprehensive Guide

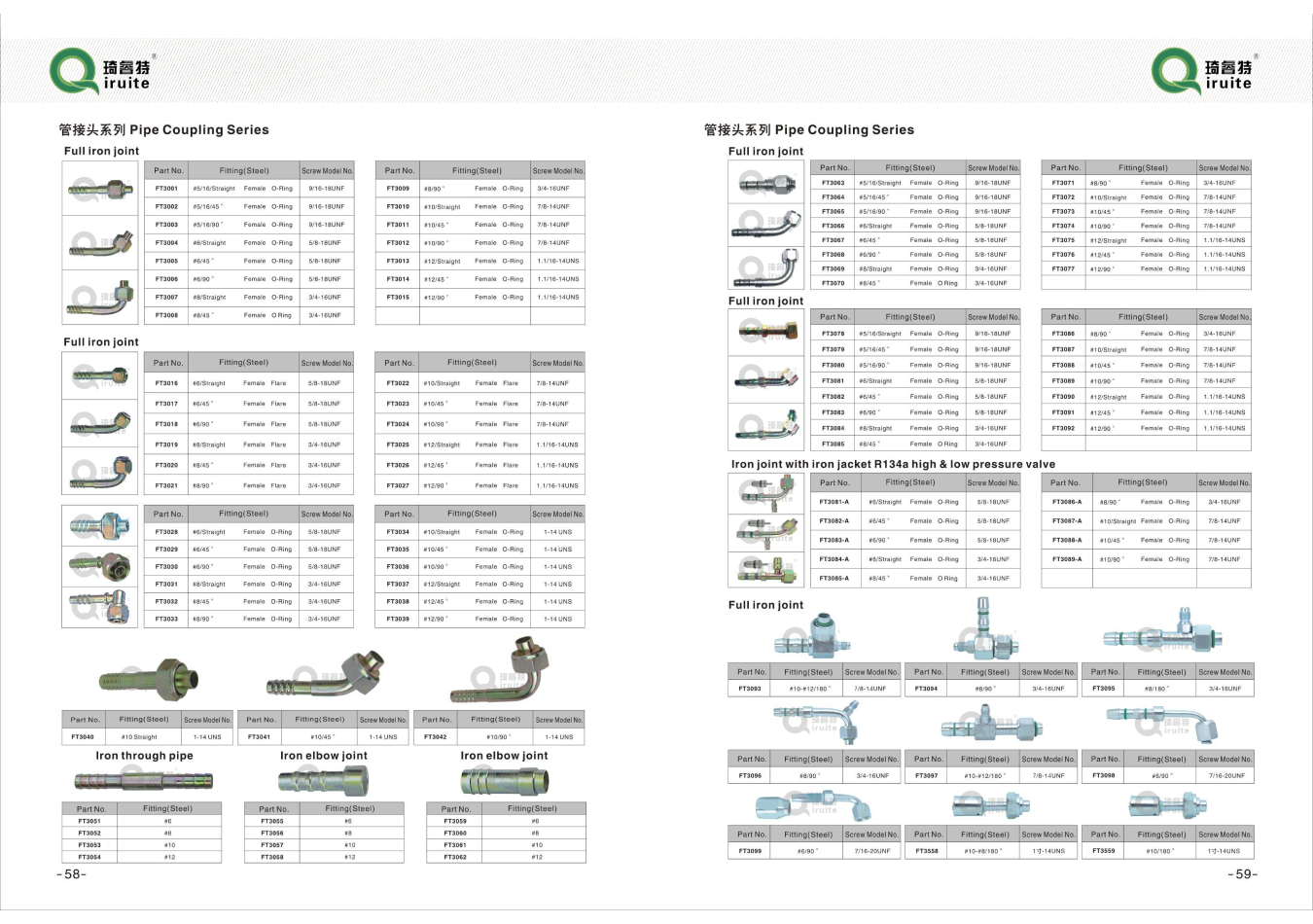

In the world of plumbing and piping systems, threaded pipe couplings play a critical role in ensuring that pipes connect securely and efficiently. Among the various sizes available, the 6-inch threaded pipe coupling is a common choice for a wide range of applications, especially in industrial settings, commercial constructions, and even residential plumbing systems.

What is a Threaded Pipe Coupling?

A threaded pipe coupling is a fitting that joins two lengths of pipe together. Typically made from metals such as steel, brass, or PVC, these couplings incorporate a threaded interior, allowing the two pipes to be screwed into the coupling. The threaded design is essential as it provides a strong and leak-resistant connection, making it ideal for high-pressure applications.

Applications of 6-Inch Threaded Pipe Couplings

The versatility of 6-inch threaded pipe couplings allows them to be used in various industries and applications. Some common uses include

1. Water Supply Systems Many municipal water systems utilize 6-inch threaded pipe couplings to connect pipes that transport potable water. Their robust design ensures that there are minimal risks of leaks over time.

2. Sewer and Drainage Systems In wastewater management, these couplings connect larger pipes efficiently, maintaining the structural integrity and flow of the system.

4. HVAC Systems In heating, ventilation, and air conditioning systems, 6-inch threaded pipe couplings are sometimes used to connect ducts and pipes carrying air or refrigerants.

6 inch threaded pipe coupling

Benefits of Using 6-Inch Threaded Pipe Couplings

1. Easy Installation and Maintenance One of the primary advantages of threaded couplings is their ease of use. They can be installed quickly without the need for specialized tools or techniques. This ease also extends to maintenance and disassembly, as threaded connections can be easily unscrewed when repairs or adjustments are necessary.

2. Durability Most materials used in making 6-inch threaded pipe couplings are resistant to corrosion, heat, and pressure. This ensures a long-lasting performance, making them an economical choice over time.

3. Leak Resistance Properly installed threaded couplings form a tight seal, reducing the risk of leaks. This is critical in systems where even a small leak can result in significant losses, environmental hazards, or safety issues.

4. Versatility These couplings are available in various materials and thread types, allowing them to be used in different environments and with various types of pipes.

Installation Tips

When installing 6-inch threaded pipe couplings, it’s essential to follow certain best practices to ensure a secure and leak-free connection

- Inspect Pipe Ends Ensure that the pipe ends are threaded correctly and free from debris or damage. - Use Thread Sealant Apply an appropriate thread sealant or Teflon tape to the threads before screwing the pipes into the coupling. This adds an extra layer of protection against leaks. - Do Not Over-tighten While it may be tempting to tighten the connection as much as possible, over-tightening can damage the threads and lead to leaks. A firm, yet careful approach is advisable.

Conclusion

The 6-inch threaded pipe coupling is a vital component in many piping systems, providing the necessary connections for safe and efficient operation. By understanding its applications, benefits, and installation procedures, both professionals and DIY enthusiasts can ensure that their plumbing and piping systems function seamlessly. In choosing the right couplings and using them properly, you can avoid costly repairs and maintain the integrity of your piping systems for years to come.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025