hose pipe coupling joint

Understanding Hose Pipe Coupling Joints A Comprehensive Overview

Hose pipe coupling joints are essential components in various industries, facilitating the connection between hoses and ensuring a seamless flow of fluids or gases. These couplings are crucial for applications in agriculture, construction, manufacturing, and even in home gardening. As such, understanding the different types of hose pipe coupling joints, their applications, and maintenance practices is vital for anyone working with fluid transfer systems.

Types of Hose Pipe Coupling Joints

There are several types of hose pipe coupling joints, each designed for specific applications. The most common types include

1. Cam Lock Couplings Widely used in agriculture and industrial applications, cam lock couplings allow quick disconnection and reconnection of hoses. The couplings feature levers that securely lock the hose in place, providing an efficient and reliable solution for fluid transfer.

2. Hose Barb Fittings These fittings are designed for permanent connections. A hose barb fitting fits inside the hose, and when clamped, it forms a tight seal. They are commonly used in situations where hoses will not be frequently disconnected.

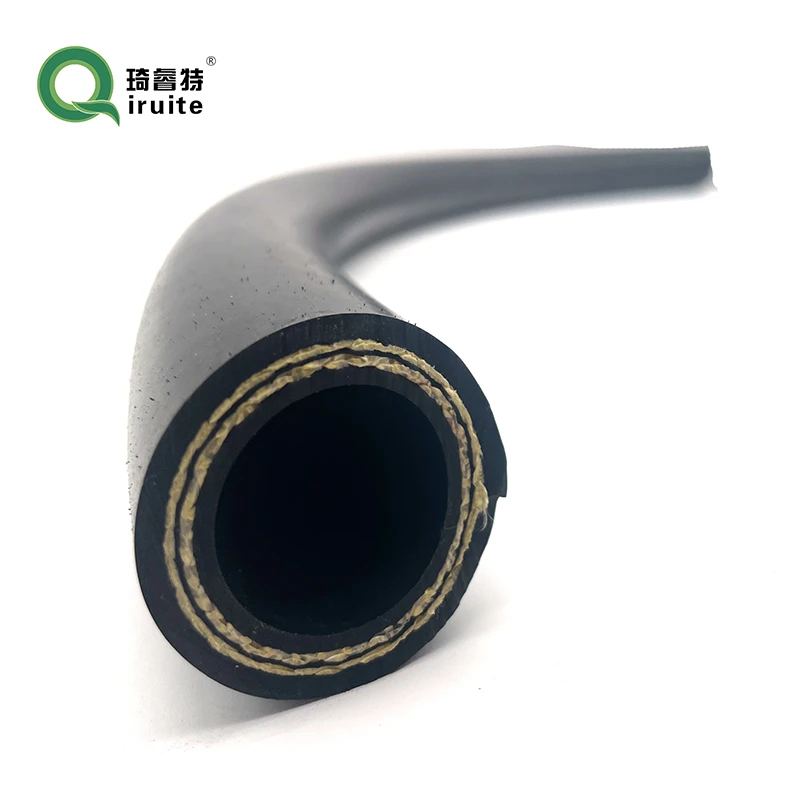

3. Threaded Couplings These can be male or female and feature screw threads that allow for secure attachment. Threaded couplings are often used in situations requiring high-pressure applications, such as in hydraulic systems.

hose pipe coupling joint

4. Quick Connect Couplings Ideal for applications requiring frequent changes of hoses, quick connect couplings allow for swift disconnections without the need for tools.

Applications in Various Industries

Hose pipe coupling joints find applications in numerous settings. In agriculture, they facilitate the transfer of water and fertilizers, ensuring efficient irrigation. In construction, these couplings are vital for transferring liquids such as concrete and cleaning agents. Similarly, industries that require fluid transfer, like chemical manufacturing, utilize these couplings for process efficiency.

Maintenance and Best Practices

To ensure the longevity and reliability of hose pipe coupling joints, regular maintenance is essential. Inspecting couplings for signs of wear and tear, ensuring proper alignment during connections, and using the appropriate types of seals and clamps can prevent leaks and failures. It is also crucial to choose the right material for the coupling joint, considering factors like pressure, temperature, and the type of fluid being transported.

In conclusion, hose pipe coupling joints are indispensable in modern-day fluid transfer systems. By understanding their types, applications, and maintenance practices, users can ensure optimal performance and safety in their applications. Whether in agriculture, construction, or any other industry, the right coupling can make all the difference in efficiency and reliability.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025