3% 204% Male Threaded Connector for Reliable Pipe Joint Applications

Understanding 3% 204% Male Threaded Coupling An Overview

In the world of plumbing, construction, and mechanical engineering, the importance of properly connecting different components cannot be overstated. One of the most significant connections in these fields involves male threaded couplings, specifically those classified as 3% 204%. This article will explore what 3% 204% male threaded coupling is, its applications, benefits, and the importance of correct usage in various systems.

Definition and Specifications

A male threaded coupling is a fitting used to connect two female-threaded pipes or fittings. It has external threads on one or both ends, which allows it to screw into female threads. The designation 3% 204% refers to specific measurements and standards that apply to these couplings. The 3% may indicate the diameter of the threads, while 204% may refer to the material composition or strength of the coupling. Understanding these specifications is essential for engineers and plumbers to ensure compatibility with existing systems.

Applications

3% 204% male threaded couplings are widely used in various industries, including

1. Plumbing and Water Supply They are essential in connecting pipes that transport water in residential and commercial settings. Ensuring a tight seal is crucial to prevent leaks and maintain water pressure.

2. Oil and Gas Industry These couplings are used in pipelines to connect different sections and maintain the flow of crude oil, natural gas, and refined products. They must withstand high pressures and corrosive environments.

3. HVAC Systems In heating, ventilation, and air conditioning systems, these couplings help connect refrigerant lines and ensure efficient heat exchange.

4. Industrial Machinery Many machines require the transfer of fluids or gases, and the 3% 204% male threaded coupling plays a vital role in creating secure connections.

Benefits

The use of 3% 204% male threaded couplings offers several advantages

3 4 male threaded coupling

2. Easy Installation The threaded design simplifies the installation process. Professionals can quickly connect or disconnect components, minimizing downtime during repairs or upgrades.

3. Leak Prevention Properly installed couplings provide a tight seal, reducing the risk of leaks that can lead to costly damage and repairs.

4. Versatility Available in various sizes and materials, 3% 204% male threaded couplings can be used in numerous applications across different industries.

Importance of Correct Usage

Despite their benefits, the effectiveness of 3% 204% male threaded couplings largely depends on correct usage. Here are some key considerations

1. Thread Compatibility Always ensure that the threads of the coupling match the female threads of the components being connected. Mismatched threads can lead to ineffective seals and leaks.

2. Material Suitability Different environments require different materials; for instance, stainless steel couplings may be needed in corrosive environments, while plastic couplings may suffice in less harsh settings.

3. Torque Specifications Following the manufacturer’s torque specifications is crucial during installation. Over-tightening can damage the coupling, while under-tightening can lead to leaks.

4. Regular Maintenance Regular inspections and maintenance of threaded connections can help identify potential issues before they exacerbate, thus ensuring the longevity and reliability of the systems in which they are used.

Conclusion

In conclusion, 3% 204% male threaded couplings are essential components across various industries for creating reliable connections between pipes and fittings. Their durability, ease of installation, and versatility make them an invaluable asset in plumbing, oil and gas, HVAC, and industrial settings. Understanding their specifications and proper usage is crucial for ensuring that these couplings perform effectively, contributing to the overall efficiency and safety of the systems they serve. Engaging with these components knowledgeably can lead to more efficient project executions and minimize the risk of costly downtimes. As industry standards continue to evolve, staying informed about the latest developments in coupling technology will be key for professionals in the field.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

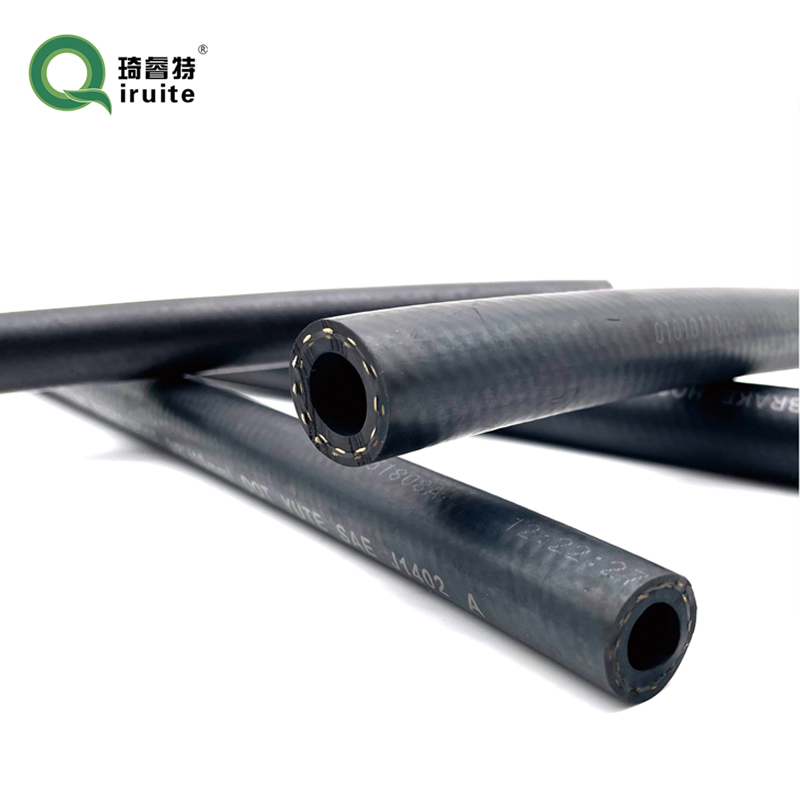

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025