Brake Hose Safety and Replacement Insights

A vehicle’s braking system is a marvel of engineering, relying on precision components like the brake hose, brake line fitting, and durable hydraulic lines to ensure safety. When any part of this system fails, the consequences can be catastrophic. Understanding the role of these components, their maintenance needs, and the brake line replacement price is critical for every vehicle owner. This article explores how brake hoses and fittings function, factors affecting replacement costs, and practical tips to keep your braking system in optimal condition.

The Vital Role of Brake Hoses in Vehicle Safety

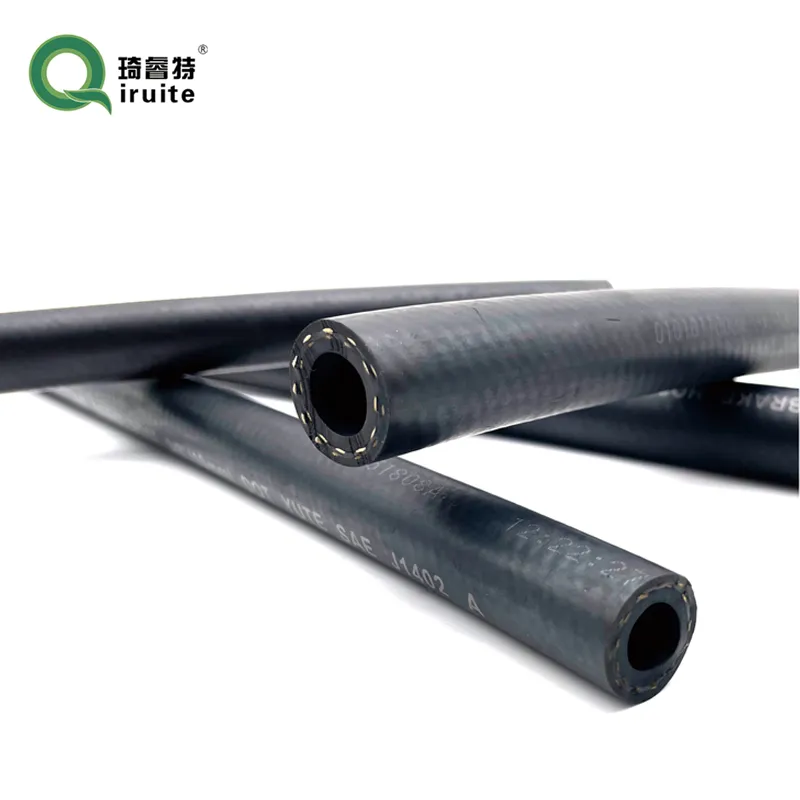

The brake hose is a flexible, reinforced rubber or thermoplastic tube that connects the brake calipers or wheel cylinders to the vehicle’s stationary metal brake lines. Its primary function is to transmit hydraulic pressure from the master cylinder to the brakes, allowing them to engage when the pedal is pressed. Over time, brake hoses can degrade due to heat, moisture, or physical wear, leading to cracks, bulges, or leaks.

A failing brake hose compromises braking efficiency, often resulting in a spongy pedal feel or uneven braking. Regular inspections are essential, especially in older vehicles or those driven in harsh conditions. Replacing a damaged brake hose promptly prevents brake fluid loss and ensures consistent pressure delivery.

Brake Line Fittings: Types, Functions, and Maintenance

Brake line fittings are small but crucial connectors that join sections of brake lines or attach hoses to other components. Made from materials like steel or brass, these fittings ensure airtight seals to maintain hydraulic pressure. Common types include flare fittings, compression fittings, and banjo bolts, each designed for specific applications.

Corrosion is the primary enemy of brake line fittings. Rust or debris can compromise their integrity, leading to leaks or sudden failures. During brake line replacement, technicians often inspect fittings for wear and replace them if necessary. Using high-quality fittings during repairs ensures longevity and reduces the risk of future issues.

Understanding Brake Line Replacement Price Factors

The brake line replacement price varies widely depending on several factors. Labor costs typically account for 50–70% of the total expense, as accessing and replacing brake lines can be time-consuming, especially in vehicles with complex routing. Material costs also play a role: stainless steel lines last longer but cost more than standard steel.

Vehicle make and model influence pricing too. Luxury or rare vehicles may require custom parts, increasing the brake line replacement price. Geographic location matters as well—labor rates differ between urban and rural areas. To avoid surprises, always request a detailed estimate that breaks down parts, labor, and potential additional fees.

Maximizing Brake System Longevity: Brake Hoses, Fittings, and Costs

Proactive maintenance is the best way to minimize brake line replacement price overhauls. Regularly inspect brake hoses for cracks or soft spots and check fittings for corrosion. Flushing brake fluid every two years prevents moisture buildup, which can corrode metal lines and fittings.

When replacements are unavoidable, opt for OEM or high-quality aftermarket parts. While cheaper alternatives might reduce upfront costs, they often fail sooner, leading to higher long-term expenses. Prioritize safety over savings—never delay repairs if your braking system shows signs of wear.

Brake Hose FAQs

What are the warning signs of a failing brake hose?

A deteriorating brake hose may cause a spongy brake pedal, visible fluid leaks, or uneven braking. If the pedal sinks to the floor or the vehicle pulls to one side during stops, inspect the brake hoses immediately.

How do brake line fittings affect overall brake performance?

Brake line fittings ensure leak-free connections between brake components. Damaged or corroded fittings can lead to pressure loss, reducing braking power and increasing the risk of brake line replacement down the line.

Why does brake line replacement price vary between shops?

Labor rates, part quality, and vehicle complexity all influence the brake line replacement price. Shops in high-cost areas or those specializing in luxury vehicles often charge more.

Can I replace a brake hose myself to save money?

While DIY brake hose replacement might lower labor costs, improper installation can cause brake failure. Unless you’re experienced, leave this task to professionals to ensure safety.

How often should brake line fittings be inspected?

Inspect brake line fittings during routine maintenance or whenever brake work is performed. Address corrosion or leaks immediately to avoid costly brake line replacement price surprises.

Your vehicle’s braking system is only as reliable as its weakest component. By understanding the roles of brake hoses, fittings, and the factors influencing replacement costs, you can make informed decisions that prioritize safety and value. Regular inspections, timely repairs, and investing in quality parts will keep your brakes functioning flawlessly for years to come.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightžiniosNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapžiniosNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionžiniosNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurabležiniosNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StabležiniosNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurabležiniosNov.10,2025