Understanding the Importance of Pipe Coupling in Plumbing and Piping Systems

Understanding Pipe Couplings A Key Component in Piping Systems

Pipe couplings are essential components in various piping systems, serving as straightforward yet vital connectors between two pipe lengths. They play a crucial role in industrial, residential, and commercial applications, ensuring the effective transport of fluids, gases, and other materials. This article delves into the significance of pipe couplings, their types, applications, and installation methods.

What is a Pipe Coupling?

A pipe coupling is a fitting that joins two sections of a pipe, allowing for the continuation of the pipeline. It provides a sealed connection to prevent leaks and ensure fluid integrity during transportation. Couplings can be made from various materials, including metal, plastic, and rubber, each suitable for different applications based on pressure, temperature, and environmental conditions.

Types of Pipe Couplings

There are several types of pipe couplings, each designed for specific needs

1. Compression Couplings These are used to connect two pipes without soldering or welding. They consist of a hollow cylinder tightened by a nut, which compresses a rubber gasket around the pipe, creating a tight seal.

2. Screw Couplings Often used in smaller diameter pipes, these couplings feature threads that allow them to be screwed onto the pipe ends, creating a strong and leak-proof joint.

3. Welded Couplings Typically employed in high-pressure systems, these couplings are welded onto the pipe ends, creating a continuous and robust bond. This type of coupling is common in oil and gas applications.

4. Flanged Couplings These consist of two flanges that are bolted together, providing easy access for maintenance and facilitating disassembly. Flanged couplings are often used in large industrial systems.

5. Flexible Couplings Designed to accommodate slight misalignments between pipes, flexible couplings can absorb vibrations and movements. They are commonly used in sewer systems and HVAC piping.

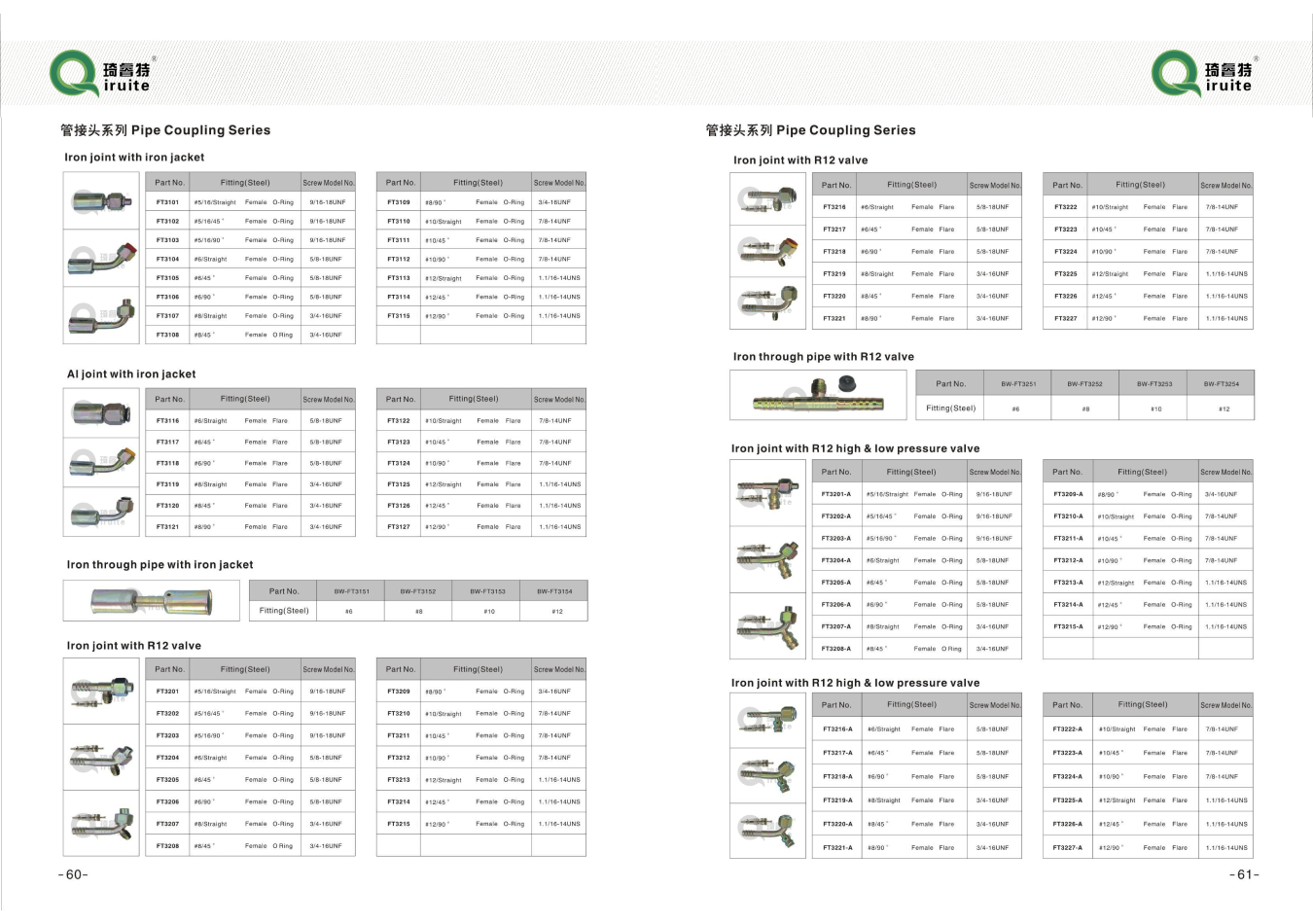

pipe coupling

Applications of Pipe Couplings

Pipe couplings are ubiquitous in various industries, including

- Water Supply Systems They connect lengths of pipes in municipal water supply and irrigation systems, ensuring the safe transport of drinking water and agricultural resources.

- Oil and Gas Couplings in these industries must withstand high pressures and corrosive substances, facilitating the safe transportation of crude oil and natural gas.

- HVAC Systems In heating, ventilation, and air conditioning systems, couplings are essential for connecting various ductwork and plumbing components.

- Chemical Processing Chemical companies utilize specialized couplings that can handle corrosive materials, maintaining the integrity of the production process.

Installation and Maintenance

Proper installation of pipe couplings is crucial to ensure their functionality and longevity. It typically involves measuring the pipe length, cutting the pipes to the correct size, and securely fitting the coupling. Depending on the type of coupling, this may require tools such as wrench sets for screws or welding equipment for traditional welded connections. Regular maintenance checks should be conducted to inspect for wear, damage, or leaks, especially in high-stress environments.

Conclusion

In conclusion, pipe couplings are a fundamental aspect of piping systems across various sectors. Understanding the different types, applications, and proper installation practices can significantly impact the efficiency, safety, and maintenance of any plumbing or industrial system. Whether in water distribution, chemical processing, or HVAC systems, these small yet powerful components are vital for seamless operations.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025