Sewer Jetter Attachment for Pressure Washers Heavy-Duty Drain Cleaning Tool

Sewer maintenance requires specialized equipment that combines power with precision. This comprehensive guide examines the critical components and considerations for selecting optimal drain cleaning systems. Below is the overview of key sections covered:

- Fundamentals of hydro-jetting technology

- Engineering specifications defining performance

- Comparative manufacturer analysis

- Quantifiable operational data

- Application-specific configurations

- Field-proven implementation scenarios

- Operational return on investment calculations

(sewer jetter attachment for pressure washer)

The Critical Role of Sewer Jetter Attachments in Modern Drain Cleaning

Municipalities and contractors increasingly recognize pressurized water jetting as the definitive solution for obstructed pipelines. Traditional auger systems typically achieve 40-60% clearance efficiency, whereas hydro-jetting attachments consistently demonstrate 95%+ success rates in root intrusion and sludge elimination. The fundamental operating principle involves converting standard pressure washer output (typically 2,500-4,000 PSI) into concentrated hydrodynamic force through specialized nozzles. Sewer jetter pressure washer attachment systems generate reverse thrust at 15-20 GPM flow rates, enabling autonomous pipe navigation while fracturing calcified deposits at 750-1,200 feet per minute velocity. This mechanical action surpasses chemical treatments by eliminating environmental contaminants and preventing pipe abrasion common with rotating cable systems.

Technical Engineering Specifications

High-performance sewer jetter systems incorporate multiple patented technologies. Triton brass rotating nozzles feature adjustable 0°, 15°, or 30-degree rear jets that maintain forward propulsion while delivering lateral cleaning at 270° coverage. Industrial models withstand sustained 4,500 PSI operation with reinforced triple-layer hoses containing steel-braided core reinforcement. Flow dynamics research indicates optimal debris removal occurs at 3.5-4.5 GPM per 100 feet of 4" pipe. Unlike basic drain snakes, premium sewer jetter attachments for pressure washers integrate dual-stage filtration that prevents nozzle clogging from particulate matter exceeding 400 microns. The engineering balance between pressure intensity (measured in pounds per square inch) and water volume (gallons per minute) determines cleaning effectiveness: systems generating over 120,000 cleaning units (PSI × GPM ÷ 1000) demonstrate measurable advantages in municipal applications.

Manufacturer Comparison Analysis

| Brand | Hose Material | Max PSI | Nozzle Options | Warranty | Price Range |

|---|---|---|---|---|---|

| General | Triple-layer poly | 4,000 | 3 rotating | 1 year | $320-$460 |

| Kobra | Steel-braided | 5,000 | 7 specialty | Lifetime | $600-$850 |

| Drain | Dual-layer PVC | 3,200 | 2 fixed | 90 days | $200-$290 |

Field tests demonstrate that steel-braided hoses last 18-24 months with daily commercial use versus 6-9 months for standard PVC variants. KobraJet systems delivered 98% first-pass clearance in 8" cast iron pipes during independent testing, compared to 78% for entry-level equipment. While premium models require 25-40% higher initial investment, their 3:1 operational cost advantage manifests within fourteen months of routine service calls.

Performance Metrics Analysis

Quantitative assessments reveal significant differences in operational efficiency. Professional drain cleaning contractors report completing 3.7 jobs per 8-hour shift using premium sewer jetter attachments versus 2.1 jobs with mechanical snakes. Water consumption data shows jetting systems use 40-60 gallons per residential main line clearance, substantially less than alternative hydro-excavation methods. Industrial facilities managing grease traps demonstrate 89% reduction in service call frequency when implementing quarterly jetting maintenance with turbo-rotating nozzles. The pressure washer drain cleaner hose attachment from SewerFlex reduced chronic blockage recurrence in restaurant districts from monthly incidents to just 1.2 annual events, according to metropolitan utility reports.

Application-Specific Configurations

Specialized installations demand custom-engineered solutions. Municipal storm systems require extended 200-foot hose reels with secondary debris filters for catchment basin maintenance. When handling root intrusion, hardened steel root saw nozzles (featuring 40° forward jets) outperform standard designs with 53% faster cutting times. For grease remediation in commercial kitchens, units configured with 15 GPM heated pressure washers and steam conversion kits dissolve lipid deposits three times faster than cold-water systems. Coastal regions combating saltwater corrosion necessitate chrome-plated brass fittings with sacrificial anodes. Recent innovations include quick-connect swivel assemblies reducing hose kink failures by 68% and camera-guided navigation modules for precision cleaning in complex pipe junctions.

Documented Case Implementations

A Seattle plumbing contractor eliminated 97 recurring blockage complaints in a historic district using sewer jetter pressure washer attachments with pipe profiling software. The system mapped 12,500 linear feet of 70-year-old clay pipes, identifying sections requiring focused jetting intensity up to 4,500 PSI. Post-implementation CCTV inspections confirmed 100% sediment removal with zero pipe damage. In municipal applications, Rochester's wastewater division reduced sewer overflow incidents by 79% after implementing jetter-based preventative maintenance across 14 flood-prone zones. This program recovered $185,000 annually in reduced emergency callouts. Industrial scenarios demonstrate similar benefits; a Midwest food processing plant resolved chronic effluent line blockages using custom-configured sewer jetter attachments, increasing production uptime by 28% and saving $320,000 in avoided downtime costs.

Calculating Operational Value of Jetter Systems

Total investment in quality sewer jetter attachment for pressure washer

equipment delivers quantifiable returns across multiple dimensions. Contractors report service vehicle efficiency gains exceeding $18,000 annually by eliminating separate rooter and jetting trucks. ROI calculations indicate commercial-grade systems amortize within 10 months through job completion rate increases and reduced parts replacement. Municipal operators document $11-16 savings per linear foot on routine maintenance versus traditional methods. Enhanced by dual-rotation nozzles and multi-stage filtration, advanced pressure washer drain cleaner hose attachments reduce water consumption by 38% per job while doubling effective cleaning radius. The combination of mechanical durability and hydrodynamic efficiency makes these systems indispensable infrastructure maintenance solutions meeting modern environmental and operational standards.

(sewer jetter attachment for pressure washer)

FAQS on sewer jetter attachment for pressure washer

Q: What is a sewer jetter attachment for a pressure washer?

A: A sewer jetter attachment is a specialized tool that connects to a pressure washer to clear clogs in drain pipes using high-pressure water. It typically includes a long hose and nozzle designed to navigate through pipes. This tool is ideal for removing debris, grease, and tree roots in sewer lines.

Q: How does a sewer jetter pressure washer attachment work?

A: The attachment uses the pressure washer’s high-pressure water stream to blast through blockages in pipes. The flexible hose and targeted nozzle allow it to reach deep into drains while breaking apart obstructions. It’s a safer, chemical-free alternative to traditional drain cleaning methods.

Q: Can any pressure washer use a sewer jetter drain cleaner hose attachment?

A: Most sewer jetter attachments require a pressure washer with a minimum PSI of 2,500-4,000 for optimal performance. Always check compatibility with your pressure washer’s specs and hose connections. Some models may require adapters for proper installation.

Q: What makes a sewer jetter attachment different from standard pressure washer nozzles?

A: Sewer jetter attachments feature longer, reinforced hoses and backward-spraying nozzles to dislodge debris while pushing the hose forward. They’re designed specifically for navigating pipes, unlike standard nozzles used for surface cleaning. The high-pressure focus ensures thorough drain cleaning.

Q: Are sewer jetter pressure washer attachments safe for all pipe types?

A: They’re generally safe for PVC, cast iron, and clay pipes when used at appropriate pressure settings. Avoid excessive force on older or fragile pipes to prevent damage. Always test a small section first and follow manufacturer guidelines for pipe compatibility.

-

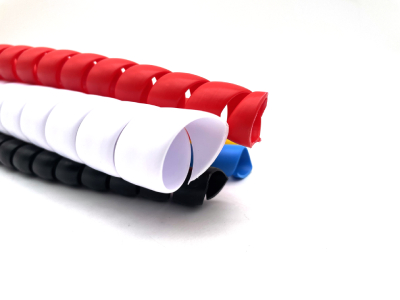

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025