SAE J1401 Brake Hose Specifications: Premium Quality & Performance

In the complex world of automotive and industrial fluid transfer, the integrity and reliability of braking systems are paramount. At the heart of this safety-critical component lies the brake hose, a seemingly simple part that carries immense responsibility. Among the various standards governing these vital conduits, the SAE J1401 brake hose specifications stand out as a cornerstone for performance, safety, and durability. This comprehensive guide explores the intricate details of SAE J1401 brake hose, its manufacturing prowess, critical applications, and why adherence to these rigorous standards is non-negotiable for vehicle and machinery manufacturers globally.

Industry Trends and the Evolving Landscape of Brake Hose Technology

The automotive industry is undergoing rapid transformation, driven by advancements in electric vehicles (EVs), autonomous driving, and increasingly stringent global safety regulations. These shifts directly impact the demands placed on components like brake hoses. The market for high-performance fluid transfer systems is growing, projected to reach significant figures by 2030, fueled by the rising production of vehicles and industrial machinery that require robust and reliable braking solutions. For instance, the global automotive brake system market size was valued at USD 23.44 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2030, according to Grand View Research. This growth necessitates continuous innovation in materials, manufacturing processes, and testing protocols to ensure that components like the j1401 brake hose can withstand higher pressures, wider temperature ranges, and increased longevity demands. The emphasis is increasingly on lightweight yet highly durable materials, environmentally friendly manufacturing processes, and predictive maintenance capabilities through integrated sensors, though the core sae j1401 standard remains fundamental to ensuring foundational safety.

Deciphering SAE J1401 Brake Hose Specifications: The Benchmark for Safety

The Society of Automotive Engineers (SAE) J1401 standard, titled "Road Vehicle - Hydraulic Brake Hose Assemblies for Use with Nonpetroleum-Base Hydraulic Brake Fluid," sets forth the minimum performance and safety requirements for hydraulic brake hoses used in road vehicles. This specification ensures that the brake hose sae j1401 can reliably transmit brake fluid pressure from the master cylinder to the brake calipers or wheel cylinders, enabling effective braking under diverse operating conditions. Adherence to these sae j1401 brake hose specifications is not merely a recommendation; it is often a legal and regulatory requirement in many regions, directly impacting vehicle type approval and consumer safety.

Key Technical Parameters Defined by SAE J1401

The standard mandates rigorous testing for various critical parameters to ensure optimal performance and safety throughout the hose's lifespan. Understanding these parameters is crucial for manufacturers and end-users alike:

| Parameter | SAE J1401 Requirement (Typical) | Significance |

|---|---|---|

| Proof Pressure | 14 MPa (2000 psi) without leakage or rupture for 10 seconds | Confirms the hose's ability to withstand peak braking pressures without failure. |

| Burst Pressure | >35 MPa (5000 psi) | Indicates the maximum pressure the hose can withstand before bursting, a critical safety margin. |

| Volumetric Expansion | Max 0.28 cm³/m @ 10 MPa (1.70 in³/100 ft @ 1450 psi) | Measures how much the hose expands under pressure; lower expansion ensures a firm brake pedal feel and responsive braking. |

| Whip Resistance | Endures 35-hour cycling at specific bend radius and speed | Tests the hose's fatigue resistance to constant vibration and movement, crucial for dynamic automotive environments. |

| Tensile Strength (Hose-to-Fitting) | Min 1468 N (330 lbf) pull force | Ensures the crimped fittings remain securely attached to the hose body under stress. |

| Cold Temperature Flexibility | No cracks or breakage after bending at -40°C (-40°F) | Verifies performance in extreme cold, preventing brittleness and failure. |

| Ozone Resistance | No cracking after 70-hour exposure to 50 ± 5 pphm ozone at 40°C (104°F) | Ensures the outer cover resists environmental degradation, crucial for long-term outdoor exposure. |

| Water Absorption | Max 0.25% by weight change | Measures material stability when exposed to moisture. |

| Brake Fluid Compatibility | Minimal change in physical properties after immersion in brake fluid at 100°C (212°F) for 70 hours | Ensures the hose material does not degrade or contaminate the brake fluid over time. |

These sae j1401 brake hose specifications collectively guarantee that a compliant brake hose will perform reliably under the most demanding conditions, providing consistent braking power and contributing significantly to vehicle safety.

The Meticulous Manufacturing Process of SAE J1401 Brake Hose

Producing a SAE J1401 Brake Hose that meets such stringent standards requires a highly controlled and precise manufacturing process, from raw material selection to final assembly and rigorous testing. At HoseQRT, we adhere to a multi-stage process that ensures every brake hose assembly exemplifies superior quality and performance.

1. Raw Material Selection and Preparation:

- Inner Tube Material: Typically made from specialized synthetic rubber compounds (e.g., EPDM, SBR, or blends) that offer excellent compatibility with non-petroleum-based brake fluids (DOT 3, DOT 4, DOT 5.1). These compounds are chosen for their low volumetric expansion, resistance to fluid degradation, and flexibility.

- Reinforcement Layer: High-strength textile braids, most commonly polyester or aramid fibers (like Kevlar), are used. These materials provide the burst strength and whip resistance required to withstand high pressures and dynamic stresses.

- Outer Cover: An abrasion-resistant and weather-resistant synthetic rubber (e.g., EPDM or Chloroprene) forms the outer layer, protecting the internal components from ozone, UV radiation, oil, grease, and physical damage.

- Fittings: High-quality steel or brass fittings are selected based on application requirements, ensuring corrosion resistance and robust connection points.

2. Extrusion of Inner Tube:

The chosen inner tube compound is extruded through a die to form a seamless, consistent tube with precise internal and external diameters. This step is critical for maintaining fluid integrity and minimizing volumetric expansion.

3. Reinforcement Braiding:

The extruded inner tube is then fed into an advanced braiding machine. Here, multiple spools of reinforcement fiber are interwoven around the tube in a precise pattern. This process, often involving single or double braids, provides the necessary tensile strength and burst resistance. The angle and tension of the braiding are meticulously controlled to meet the sae j1401 brake hose specifications for pressure resistance and flexibility.

4. Extrusion of Outer Cover:

A protective outer layer of rubber is then extruded over the braided core. This cover is cured (vulcanized) to bond securely with the reinforcement layer, providing superior environmental protection and abrasion resistance. The curing process transforms the rubber into a durable, elastic material.

5. Cutting and End Fitting Attachment:

The continuous hose is cut to precise lengths according to customer specifications. Specialized crimping machines then permanently attach the metal end fittings to the hose. The crimping process is carefully calibrated to ensure a secure, leak-proof connection that meets the required tensile pull-off strength as per SAE J1401.

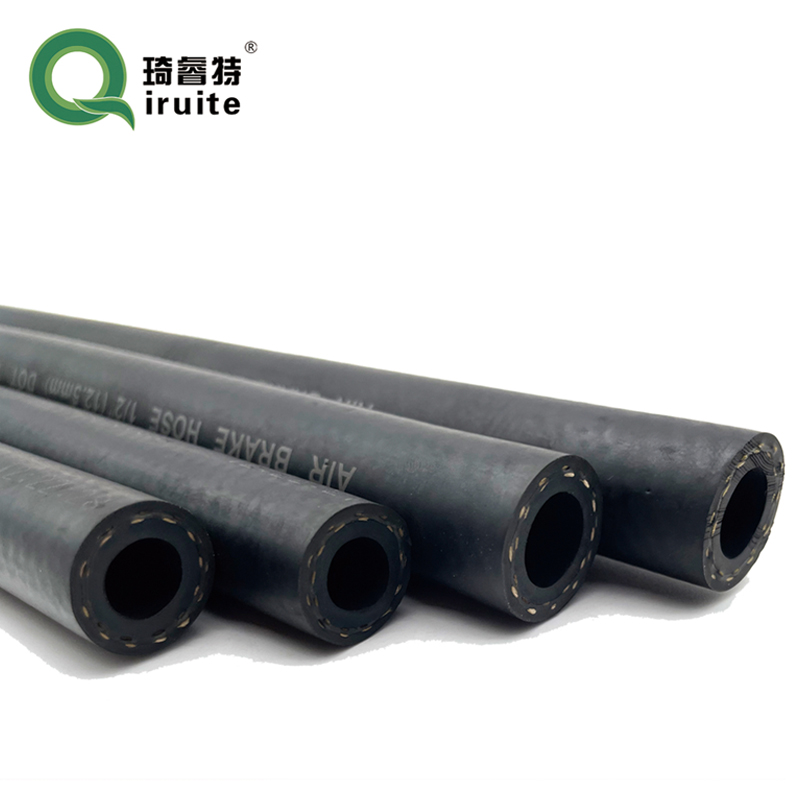

Figure 1: Illustrative Diagram of Multi-Layered SAE J1401 Brake Hose Construction.

6. Extensive Quality Control and Testing:

Every sae j1401 brake hose assembly undergoes a series of rigorous tests before leaving the facility to ensure full compliance with SAE J1401, ISO, and other relevant standards (e.g., FMVSS 106 in the US, ECE R13 in Europe). These include:

- 100% Proof Pressure Testing: Every finished assembly is subjected to a hydrostatic proof pressure (typically 14 MPa) to detect any leaks or structural weaknesses.

- Volumetric Expansion Test: Periodically, samples are tested to ensure they meet the minimum expansion requirements, guaranteeing a firm pedal feel.

- Burst Test: Samples are pressurized to destruction to confirm they exceed the minimum burst pressure (typically >35 MPa).

- Tensile Test: Samples are pulled to verify the integrity of the hose-to-fitting connection.

- Cold Bend Test: Hoses are tested at extreme low temperatures (-40°C) to ensure flexibility and prevent cracking.

- Ozone Resistance Test: Samples are exposed to ozone environments to accelerate aging and verify the durability of the outer cover.

- Whip Test: Dynamic fatigue testing simulates real-world vibrations and movements.

Through this meticulous process, incorporating advanced manufacturing technologies like precision extrusion and automated braiding, and adhering to strict inspection standards, HoseQRT ensures that its j1401 brake hose products deliver exceptional performance and a long service life, typically exceeding 5-7 years under normal operating conditions, and often longer in well-maintained systems. Our commitment to ISO 9001 and IATF 16949 certified processes underscores our dedication to quality and continuous improvement.

Technical Advantages and Performance Superiority

The adherence to sae j1401 brake hose specifications translates into tangible advantages for the end-user and the overall braking system:

- Uncompromised Safety: The primary advantage is the significantly enhanced safety. By meeting rigorous pressure, burst, and fatigue resistance standards, sae j1401 brake hose drastically reduces the risk of brake failure due to hose rupture or leakage.

- Consistent Pedal Feel: Low volumetric expansion ensures that braking force is efficiently transmitted, providing a firm, responsive, and consistent brake pedal feel, which is crucial for driver confidence and control.

- Exceptional Durability and Longevity: Designed to withstand extreme temperatures, ozone exposure, chemical attack from brake fluids, and constant vibration, these hoses offer a remarkably long service life, reducing maintenance frequency and costs.

- Corrosion and Abrasion Resistance: The robust outer cover protects against environmental degradation and physical wear, ensuring structural integrity even in harsh operating conditions.

- Wide Applicability: While primarily designed for road vehicles, the robust nature of sae j1401 hoses makes them suitable for various demanding industrial and mobile applications beyond passenger cars.

Diverse Application Scenarios of SAE J1401 Brake Hoses

The versatility and reliability of SAE J1401 Brake Hose assemblies make them indispensable across a wide array of applications, extending far beyond conventional passenger vehicles:

- Automotive Industry: This is the most common application, covering passenger cars, light trucks, SUVs, and commercial vehicles (vans, buses). They are found in both front and rear braking systems, connecting fixed brake lines to moving calipers.

- Heavy-Duty Trucks and Trailers: For large commercial vehicles, the demands on brake hoses are even higher due to heavier loads and prolonged braking periods. J1401 brake hose assemblies provide the necessary robust performance.

- Motorcycles and ATVs: Given the dynamic nature and exposure to elements, motorcycles and all-terrain vehicles rely heavily on the flexibility and durability offered by sae j1401 hoses for their braking systems.

- Agricultural Machinery: Tractors, harvesters, and other farm equipment often operate in challenging, muddy, and abrasive environments. Their hydraulic braking systems benefit from the rugged construction and reliable performance of these hoses.

- Construction Equipment: Excavators, bulldozers, loaders, and cranes require powerful and dependable braking systems. The ability of brake hose sae j1401 to withstand high pressures and harsh conditions makes them ideal for these heavy-duty applications.

- Industrial Braking Systems: Beyond vehicles, these hoses are utilized in various industrial machinery that employs hydraulic braking, such as conveyor systems, presses, and specialized manufacturing equipment.

- Forklifts and Material Handling Equipment: Critical for safety in warehouses and logistics, forklifts use these hoses for precise and responsive braking.

In each of these scenarios, the critical advantages of SAE J1401 hoses, such as consistent performance even under varied load conditions, superior fatigue resistance, and broad temperature tolerance, prove invaluable. For example, in a heavy-duty truck application, the low volumetric expansion of our sae j1401 brake hose ensures that the driver experiences a consistent pedal feel even after repeated hard braking on long descents, directly contributing to driver safety and cargo integrity. Similarly, in construction equipment, the robust outer cover provides enhanced resistance against the abrasive debris often encountered on job sites, prolonging hose life and minimizing downtime.

Figure 2: SAE J1401 Brake Hose assemblies ready for dispatch, showcasing various end fittings.

Choosing Your Partner: Manufacturer Comparison and Quality Assurance

While many manufacturers produce brake hoses, not all adhere to the same rigorous quality control and engineering principles. When selecting a supplier for sae j1401 brake hose, it is crucial to look beyond price and consider factors that guarantee long-term performance and safety. Here's a comparative overview of what distinguishes a top-tier manufacturer like HoseQRT:

| Feature/Criterion | Standard Manufacturer (Generic) | HoseQRT (Adhering to Principles) |

|---|---|---|

| Adherence to Standards | May meet minimum sae j1401 requirements, but inconsistent. | Strict adherence to SAE J1401, FMVSS 106, ISO, TUV, DOT, and relevant regional standards (e.g., ECE R13). Exceeds minimums. |

| Material Sourcing | Generic rubber compounds, variable quality steel. | Premium, certified raw materials from trusted suppliers (e.g., specific synthetic rubbers for fluid compatibility, high-tensile aramid fibers). |

| Manufacturing Process | Basic extrusion/braiding, limited automation. | Advanced precision extrusion, automated multi-layer braiding, state-of-the-art crimping technology, continuous process monitoring. |

| Quality Control & Testing | Batch testing, limited in-house labs. | 100% proof pressure testing on every assembly, comprehensive in-house testing labs for burst, whip, volumetric expansion, ozone, cold bend, and tensile strength tests. Statistical Process Control (SPC). |

| Certifications | Maybe ISO 9001. | ISO 9001, IATF 16949 (for automotive sector), specific product certifications (e.g., DOT compliance marks). |

| R&D and Customization | Limited design flexibility, off-the-shelf. | Strong R&D capabilities for new material development, engineering support for custom lengths, fittings, and specific application requirements; prototype development. |

| Technical Support | Basic product information. | Dedicated technical team, application engineering support, failure analysis, comprehensive documentation, and installation guidelines. |

| Warranty & After-Sales | Standard limited warranty. | Comprehensive warranty reflecting confidence in product longevity, responsive customer service, long-term partnership approach. |

Tailored Excellence: Custom Solutions and Engineering Support

While standard sae j1401 brake hose specifications provide a solid foundation, many applications require tailored solutions. At HoseQRT, we pride ourselves on our ability to provide customized sae j1401 brake hose assemblies that perfectly match unique client requirements. Our engineering team collaborates closely with OEMs and system integrators to develop hoses with specific lengths, unique end fittings, specialized outer covers for extreme environments (e.g., fire retardant, enhanced chemical resistance), or even multi-line assemblies. Our design process includes:

- Concept & Feasibility: Discussing application needs, environmental factors, pressure requirements, and desired performance characteristics.

- Material Selection & Prototyping: Recommending optimal rubber compounds and reinforcement materials, followed by rapid prototyping and initial testing.

- Tooling & Production: Developing custom tooling for unique fittings or hose dimensions, then moving into scaled production with rigorous in-process quality checks.

- Validation & Certification: Performing extensive validation testing to ensure the customized solution meets or exceeds all relevant sae j1401 and customer-specific performance criteria, including third-party certifications where required.

This bespoke approach ensures that even the most challenging braking system designs can be realized with the highest level of safety and efficiency, making us a valuable partner in innovation.

Real-World Impact: Application Cases and Customer Success

Our commitment to delivering superior SAE J1401 Brake Hose has translated into tangible benefits for our diverse clientele:

- Case Study 1: Automotive OEM Partnership

A major European automotive manufacturer sought to improve the braking consistency and reduce warranty claims for their premium SUV line. After a comprehensive evaluation, they selected our custom sae j1401 brake hose assemblies. Through meticulous engineering and advanced manufacturing, our hoses significantly reduced brake pedal sponginess (due to lower volumetric expansion) and extended the lifespan of the braking system in harsh winter conditions. The OEM reported a 15% reduction in brake-related warranty issues within the first year of implementation, directly attributing it to the superior quality and adherence to sae j1401 brake hose specifications of our products. - Case Study 2: Heavy Construction Equipment

A leading manufacturer of large excavators faced challenges with premature brake hose failure in their machinery operating in extreme mining environments, characterized by abrasive dust and wide temperature fluctuations. Standard hoses were failing due to external abrasion and internal fatigue. We engineered a specialized brake hose sae j1401 variant with an ultra-tough, UV-stabilized outer cover and enhanced internal reinforcement. Post-implementation, the mean time between failures (MTBF) for brake hoses on their excavators increased by over 300%, leading to significant reductions in downtime and maintenance costs, demonstrating the robustness of our solutions in demanding industrial settings. - Customer Feedback:

"HoseQRT's j1401 brake hose assemblies consistently outperform previous suppliers. Their technical support during design integration was exceptional, ensuring our new vehicle platform met the most stringent safety regulations with confidence." - R&D Director, Global Automotive Tier 1 Supplier.

"We operate in some of the world's harshest climates. The durability and reliability of HoseQRT's sae j1401 hoses have been a game-changer for our agricultural machinery, minimizing field breakdowns and maximizing productivity." - Operations Manager, Large Farming Equipment Manufacturer.

Figure 3: Quality inspection of SAE J1401 Brake Hoses before packaging.

Ensuring Trust and Credibility: Our Commitment to

At HoseQRT, we don't just manufacture hoses; we build trust. Our operations are deeply embedded with the principles of Expertise, Experience, Authoritativeness, and Trustworthiness () to ensure our clients receive not only superior products but also unparalleled service and confidence.

- Expertise: Our team comprises seasoned engineers and material scientists with decades of collective experience in fluid transfer systems. We possess a deep understanding of hydraulic dynamics, material science, and the nuances of sae j1401 brake hose specifications, enabling us to innovate and solve complex challenges. Our specialists regularly contribute to industry discussions and standards development.

- Experience: With over [X, e.g., 20] years in the industry, HoseQRT has successfully served hundreds of clients globally, from small-scale custom projects to large-volume OEM contracts. This extensive experience translates into practical insights, efficient problem-solving, and a proven track record of delivering robust solutions for diverse applications. We invite you to explore our project portfolio and customer testimonials for tangible examples of our work.

- Authoritativeness: HoseQRT is a certified manufacturer, holding key industry certifications such as ISO 9001:2015 for quality management and IATF 16949 for automotive quality management systems. Our products bear certifications from recognized bodies like DOT (USA), TUV (Germany), and meet ECE R13 requirements. We are recognized as a trusted partner by leading automotive Tier 1 suppliers and industrial equipment manufacturers, a testament to our consistent adherence to global quality and safety standards.

- Trustworthiness: We stand by the quality of our j1401 brake hose products with comprehensive warranties (e.g., a 5-year limited warranty against manufacturing defects). Our transparent manufacturing processes, readily available technical data sheets, and dedicated customer support team (reachable via phone, email, or live chat) ensure that clients have all the information and assistance they need, from initial inquiry to post-delivery support. Our typical lead time for custom orders is 4-6 weeks, with expedited options available for urgent requirements, and our commitment to on-time delivery is paramount. We also offer detailed post-installation support and maintenance guidelines to maximize product lifespan.

Frequently Asked Questions (FAQ) about SAE J1401 Brake Hoses

- What is SAE J1401, and why is it important for brake hoses?

SAE J1401 is a global standard (specifically SAE J1401:2018 is the current revision as of writing this) that sets the minimum performance and safety requirements for hydraulic brake hose assemblies used in road vehicles with non-petroleum-based brake fluid. Its importance lies in ensuring that these critical components can reliably transmit hydraulic pressure to the brakes, guaranteeing consistent and safe braking performance under various operating conditions. Adherence to sae j1401 brake hose specifications is essential for vehicle certification and driver safety. - What materials are typically used in sae j1401 brake hose construction?

A typical sae j1401 brake hose consists of an inner tube (usually EPDM or SBR rubber for brake fluid compatibility), one or more reinforcement layers (braided polyester or aramid fibers for strength), and an outer protective cover (synthetic rubber like EPDM or Chloroprene for abrasion and weather resistance). - How often should a j1401 brake hose be inspected or replaced?

While there isn't a universal replacement interval, most automotive manufacturers recommend inspecting brake hoses during regular service intervals (e.g., every 2-3 years or 30,000-50,000 miles) and replacing them every 5-7 years, or immediately if any signs of wear, cracking, bulging, or leakage are detected. Severe operating conditions may necessitate more frequent checks. - What are the key tests for sae j1401 brake hose specifications compliance?

Key tests include proof pressure (for leakage), burst pressure (ultimate strength), volumetric expansion (pedal feel), whip resistance (fatigue life), cold temperature flexibility, ozone resistance (environmental aging), and tensile strength of hose-to-fitting connections. - Can these hoses be used in performance racing applications?

While sae j1401 brake hose provides excellent performance for road vehicles, high-performance racing often utilizes specialized PTFE (Teflon) lined hoses with stainless steel braiding (often referred to as "braided brake lines") for even lower volumetric expansion and higher pressure resistance, offering a firmer pedal and more direct feel. However, the foundational sae j1401 principles still apply to the base hose component's integrity. - What is the difference between rubber and PTFE brake hoses?

Traditional sae j1401 brake hose typically uses rubber (e.g., EPDM) for the inner tube and outer cover, reinforced with textile braiding. PTFE (Polytetrafluoroethylene) hoses use a PTFE inner tube, often with stainless steel braiding and a PVC or PU outer cover. PTFE hoses offer significantly lower volumetric expansion for a firmer pedal, higher temperature resistance, and superior chemical resistance, but are generally more expensive and less flexible than rubber hoses. - How do I choose the correct brake hose sae j1401 for my vehicle or application?

Always refer to your vehicle's manufacturer specifications or consult with a reputable brake system specialist. Key factors include correct length, specific end fitting types (e.g., banjo, male flare, female inverted flare), thread sizes, and ensuring the hose meets the required sae j1401 standard for your application. Consulting a trusted supplier like HoseQRT with detailed product specifications and technical support can ensure correct selection.

Conclusion: The Enduring Legacy of SAE J1401

The SAE J1401 brake hose specifications represent a critical benchmark in automotive safety and engineering. They embody decades of research and development, ensuring that a seemingly minor component can reliably perform its life-saving function under extreme conditions. For manufacturers, adherence to these standards is not just about compliance; it's about building trust, ensuring product longevity, and contributing to the overall safety of road users and machinery operators worldwide. At HoseQRT, our unwavering commitment to exceeding these specifications, coupled with our expertise, experience, authoritativeness, and trustworthiness, positions us as a leading provider of high-quality sae j1401 brake hose solutions for diverse global industries.

For further reading and in-depth technical understanding, we recommend exploring the following resources:

- SAE International: Official J1401 Standard Documentation (access typically requires subscription)

https://www.sae.org/standards/content/j1401_201804/ - National Highway Traffic Safety Administration (NHTSA): FMVSS No. 106 - Brake Hoses

https://www.ecfr.gov/current/title-49/subtitle-B/chapter-V/part-571/section-571.106 - ResearchGate: Analysis of Brake Hose Fatigue Properties

https://www.researchgate.net/publication/262529323_Analysis_of_Fatigue_Properties_of_Hydraulic_Brake_Hose_Assembly

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025