water jetter hose

Understanding Water Jetter Hoses A Comprehensive Guide

Water jetting is a powerful technique employed in various industries for cleaning, maintenance, and even cutting materials. At the core of this technology is the water jetter hose, a crucial component that enables high-pressure water to be effectively directed at surfaces or through pipes. In this article, we will delve into the intricacies of water jetter hoses, their types, applications, and maintenance, offering insights to enhance your understanding and utilization of this essential tool.

What is a Water Jetter Hose?

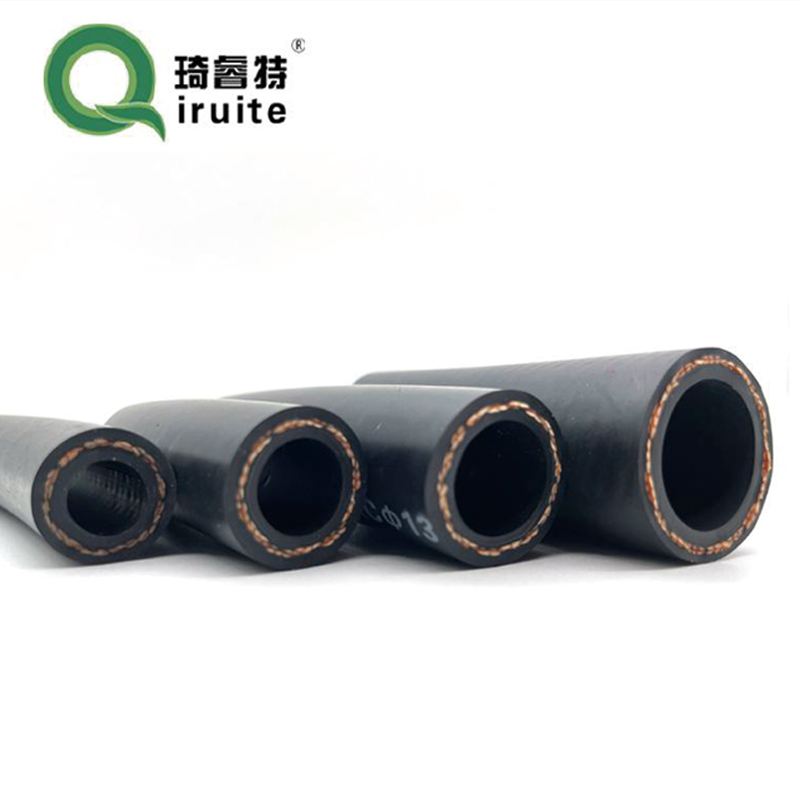

A water jetter hose is designed to withstand high pressures while delivering water for jetting applications. Typically made from durable materials such as rubber, thermoplastic, or reinforced synthetic fibers, these hoses are engineered to handle the intense pressure and wear associated with water jetting operations. They come in various sizes and lengths to accommodate different tasks, making them versatile tools for professionals in plumbing, construction, and industrial cleaning.

Types of Water Jetter Hoses

1. Standard High-Pressure Hoses These are the most common types used for general cleaning purposes. They can handle pressures ranging from 3,000 to 6,000 PSI, making them suitable for residential and commercial applications, such as drain cleaning.

2. Heavy-Duty Hoses Designed for more demanding tasks, heavy-duty hoses can operate at even higher pressures, often exceeding 8,000 PSI. They are commonly used in industrial settings where tough jobs require robust equipment.

3. Thermoplastic Hoses These hoses are lightweight and flexible, providing ease of maneuverability. They are often used in scenarios where high chemical resistance is required.

4. Reinforced Hoses These hoses are reinforced with steel or other materials, making them stronger and able to withstand extreme conditions and pressures. They are ideal for rugged environments and heavy-duty applications.

Applications

Water jetter hoses have a wide range of applications

- Drain Cleaning One of the most prevalent uses of water jetter hoses is in clearing clogged drains and sewer lines

. The high-pressure water effectively dislodges debris, grease, and other blockages.water jetter hose

- Surface Cleaning In industries such as construction and maintenance, water jetters equipped with the right hoses are used to clean surfaces, remove paint, or prepare surfaces for painting.

- Hydro Excavation In the utility sector, water jetting is often used for hydro excavation, which involves using high-pressure water to safely excavate soil. This method minimizes the risk of damaging underground utilities.

- Industrial Cleaning Water jetter hoses are also utilized in manufacturing facilities to clean equipment and machinery, ensuring optimal performance and safety.

Maintenance of Water Jetter Hoses

Proper maintenance of water jetter hoses is crucial for their longevity and effectiveness. Here are some essential tips

1. Regular Inspection Regularly check hoses for any signs of wear, punctures, or leaks. Replace any damaged hoses immediately to prevent accidents.

2. Cleaning After Use After using the hose, ensure that it is flushed with clean water to remove any debris or chemicals that may cause corrosion or wear.

3. Proper Storage Store hoses in a cool, dry place, away from direct sunlight and extreme temperatures. Use hose reels to prevent kinking and tangling.

4. Pressure Tests Periodically perform pressure tests to ensure the hose is functioning within its rated capacity.

Conclusion

Water jetter hoses are a fundamental component of effective water jetting operations. Understanding their types, applications, and maintenance can significantly enhance their effectiveness and reliability. Whether you are a professional in the industry or a DIY enthusiast, investing in high-quality water jetter hoses will yield excellent results for your cleaning and maintenance tasks. By following best practices for care and handling, you can ensure that your hose provides peak performance for years to come.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025