professional r134a manifold gauge set

Understanding the Professional R134A Manifold Gauge Set

In the realm of HVAC (Heating, Ventilation, and Air Conditioning) systems, maintaining optimal performance and efficiency is paramount. One of the essential tools for any HVAC technician is the manifold gauge set, particularly the R134A version, which is designed for use with R134A refrigerant. This article delves into the components, functions, and importance of the professional R134A manifold gauge set in the HVAC industry.

What is a Manifold Gauge Set?

A manifold gauge set is a critical diagnostic tool used in refrigeration and air conditioning systems to measure the pressure of refrigerants circulating through the system. It consists of three main components two pressure gauges, a manifold block, and hoses. The gauges display the high side (discharge) and low side (suction) pressures of the system, while the manifold block connects the gauges to the refrigerant lines.

Components of the R134A Manifold Gauge Set

1. Pressure Gauges The gauges on the manifold set are calibrated specifically for R134A refrigerant. The high side gauge typically indicates pressures ranging from 0 to about 500 psi, while the low side gauge usually ranges from 0 to 100 psi. These gauges allow technicians to determine the operational state of the HVAC system.

2. Manifold Block The manifold block is the central feature that connects the gauges to the refrigerant system. It contains valves that can open and close to isolate the system from the gauges, allowing for safe measurements and maintenance.

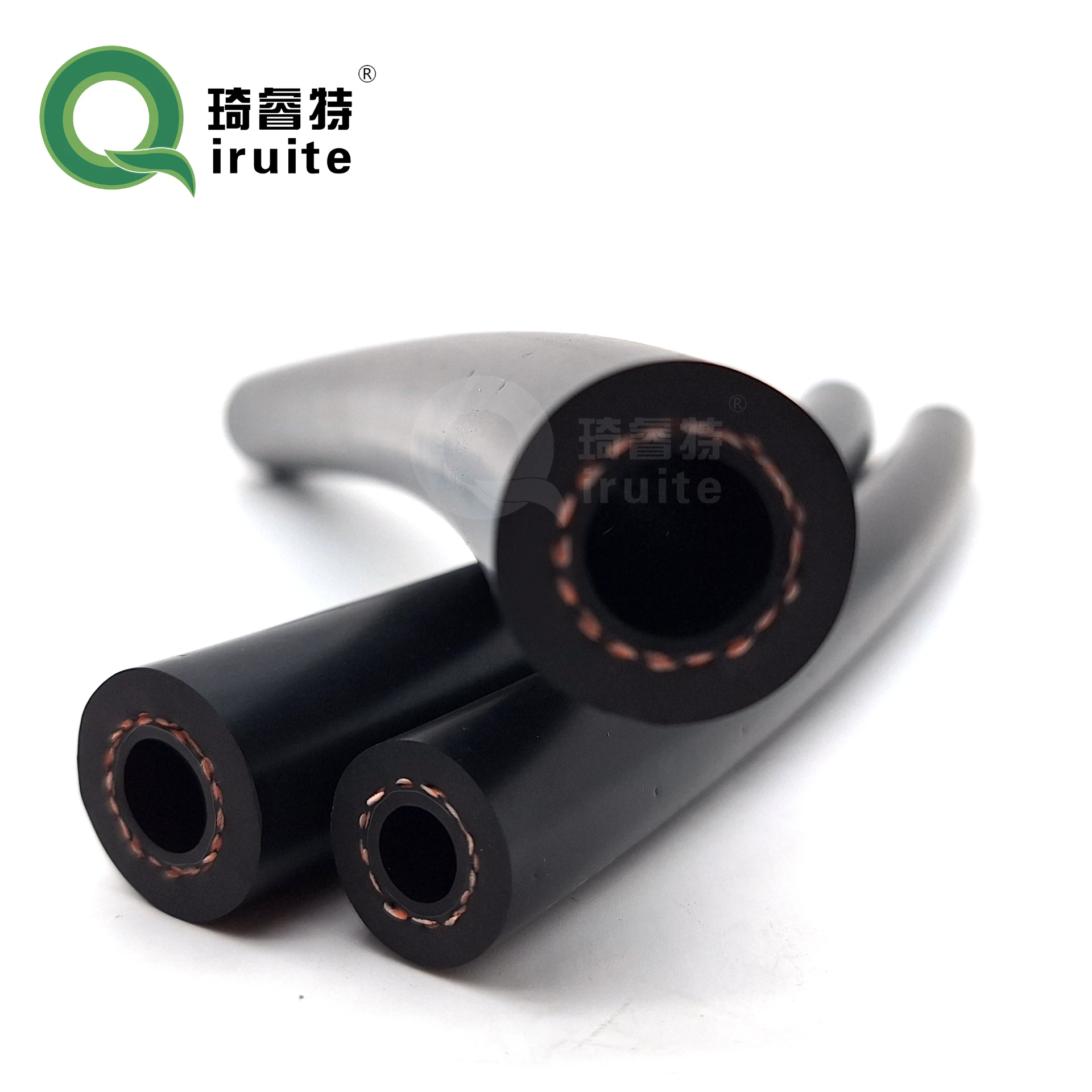

3. Hoses The hoses are color-coded for easy identification usually blue for the low side, red for the high side, and yellow for the refrigerant recovery or charging line. These hoses are designed to handle high pressures and are equipped with specialized fittings to prevent leaks.

professional r134a manifold gauge set

Functions and Applications

The primary function of the R134A manifold gauge set is to diagnose and troubleshoot air conditioning systems. By checking the pressure readings on the gauges, technicians can assess the system's performance and identify issues such as

- Refrigerant Leaks Unusually low pressures may indicate a refrigerant leak, necessitating further investigation. - Overcharging or Undercharging Correct refrigerant levels are crucial for system efficiency. The gauges help identify if the system has too much or too little refrigerant. - Blockages or Restrictions Discrepancies between the high and low side pressures can indicate blockages in the system, such as a clogged expansion valve or receiver drier. - System Efficiency Consistent monitoring of pressures can help technicians optimize the system's performance, ensuring it operates within the manufacturer's specifications.

Importance of Proper Calibration and Use

For accurate readings and effective troubleshooting, it is vital that the manifold gauge set is properly calibrated. Regular maintenance and checks ensure that the gauges provide precise measurements, which are critical for diagnosing issues accurately. Additionally, technicians should be trained in the correct usage techniques to avoid potential hazards, such as refrigerant exposure or system damage.

Conclusion

The professional R134A manifold gauge set is an indispensable tool for HVAC technicians. Its accuracy in measuring the pressures of the refrigerant system directly influences the efficiency and longevity of air conditioning and refrigeration units. By understanding the components, functions, and importance of this gauge set, technicians are better equipped to maintain and repair HVAC systems effectively. As the HVAC industry evolves, the significance of reliable tools like the R134A manifold gauge set remains constant, ensuring optimal performance and sustainability in cooling technology. Whether you are a seasoned technician or a newcomer to the field, mastering the use of this essential tool will enhance your skills and contribute to successful HVAC service and repair.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025