Understanding Pipe Couplings and Their Fittings for Effective Connecting Solutions

Understanding Pipe Coupling Fittings An Essential Component for Fluid Transfer

Pipe coupling fittings are vital components in various plumbing and industrial systems, serving as connectors between two or more sections of pipe. These fittings play a crucial role in ensuring that fluids can move through piping networks efficiently and safely. Understanding the different types of pipe coupling fittings and their applications is essential for anyone involved in plumbing, construction, or maintenance.

There are several types of pipe coupling fittings, each designed to connect pipes with specific characteristics. The most common types include slip couplings, threaded couplings, and compression couplings. Slip couplings are typically used to join two sections of pipe while allowing for slight adjustments in length. This flexibility makes them ideal for repair work or installations where precise alignment is necessary.

Threaded couplings come with internal threads that enable them to connect pipes with external threads securely. These fittings are commonly found in applications requiring a tight seal, such as gas and water lines. They are available in various materials, including metal and plastic, catering to different environmental conditions and fluid types.

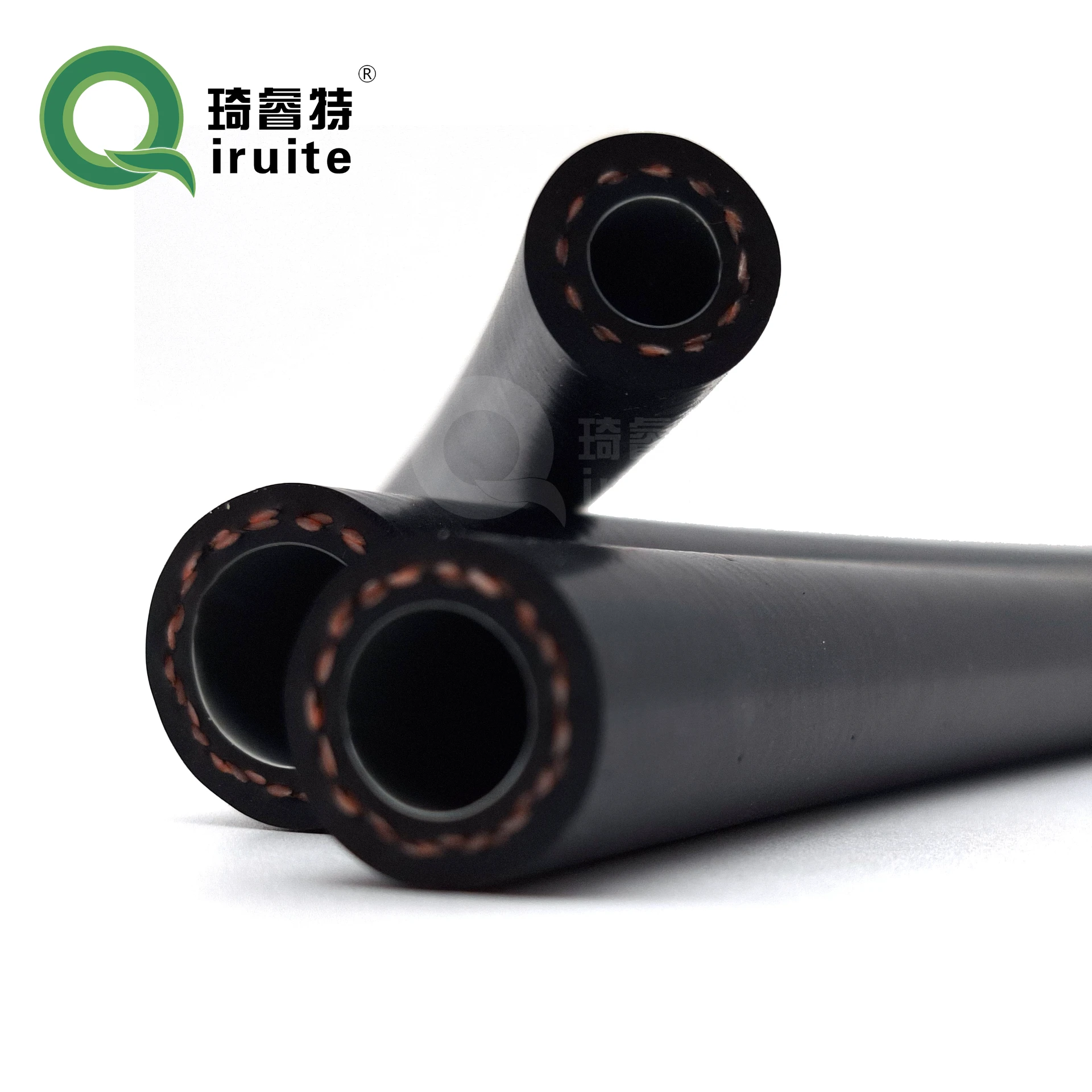

pipe coupling fitting

Compression couplings offer another alternative, especially for connecting pipes made of different materials. They work by compressing a rubber ring against the pipe ends, creating a leak-proof seal. This type of fitting is beneficial in applications where disassembly may be required, as they can be easily taken apart without damaging the pipes.

In addition to their practical uses, pipe coupling fittings come in various sizes and materials to meet specific needs. Steel, brass, PVC, and polyethylene are common materials used in pipe coupling fittings, each with its own advantages in terms of strength, corrosion resistance, and flexibility. Choosing the right material is crucial for ensuring the longevity and reliability of the piping system.

Furthermore, understanding the application of different coupling fittings is essential for effective project execution. For instance, in water supply systems, choosing fittings that can withstand pressure and corrosion is vital. Similarly, in industrial settings, compatibility with the transported fluids and the surrounding environment can dictate the choice of fittings.

In summary, pipe coupling fittings are indispensable components that facilitate the effective transfer of fluids in various systems. By understanding their types, materials, and applications, professionals can make informed decisions that enhance the functionality and longevity of piping systems, ensuring smooth and safe operations across various industries.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025