មីនា . 06, 2025 11:28

Back to list

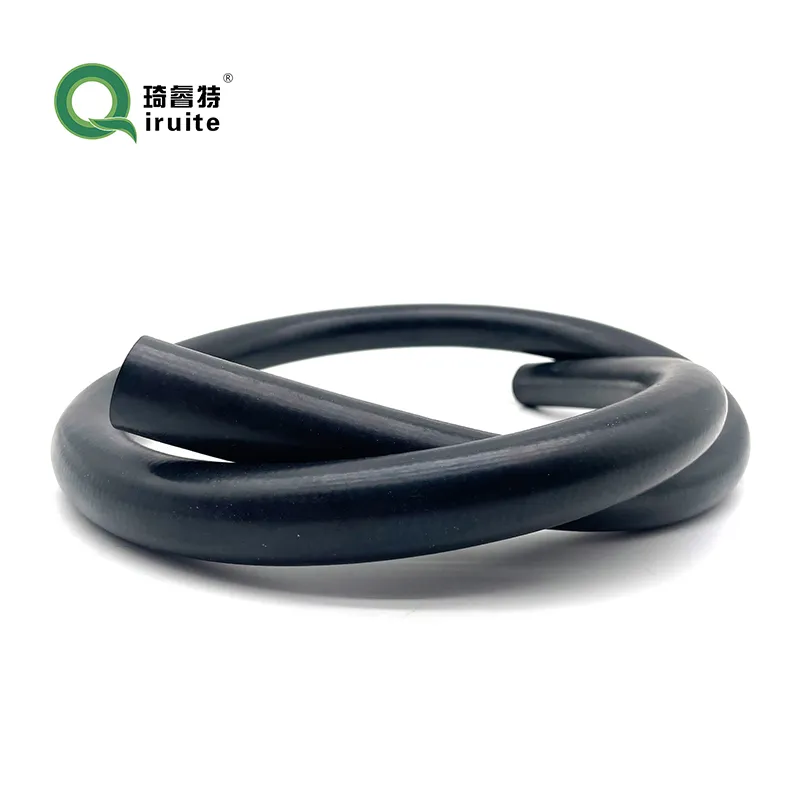

making power steering hoses

Building power steering hoses is a meticulous process that combines precision engineering with a deep understanding of automotive mechanics. This critical component ensures that steering a vehicle is both smooth and responsive, making it an essential aspect of car maintenance and performance enhancement. To create power steering hoses that stand above the rest, several elements of expertise, authority, and trustworthiness come into play, ensuring optimal performance and safety.

The trustworthiness of a power steering hose manufacturer is often reflected in their adherence to international standards such as ISO 9001 or IATF 16949, certifications that assure quality management practices are upheld. These standards demonstrate a commitment to continuous improvement and customer satisfaction, providing peace of mind to consumers and mechanics alike. Collaboration with automotive manufacturers provides a further layer of authority. Trusted hose suppliers often work directly with vehicle manufacturers to develop bespoke solutions tailored to specific models, ensuring that each hose integrates seamlessly with the vehicle's steering system for optimal performance and longevity. Consumer trust is further bolstered by thorough aftercare services and warranties offered by manufacturers. By offering extended warranties and robust customer service options, manufacturers demonstrate confidence in their products, reassured by their investment in research and development, quality materials, and precision manufacturing techniques. Advanced innovations like electronically-controlled variable assist steering further underscore the importance of high-quality power steering hoses. As automotive technology evolves toward more sophisticated systems, the role of these hoses becomes even more crucial in ensuring that drivers maintain control and safety behind the wheel. In summary, the process of manufacturing power steering hoses blends solid engineering expertise with authoritative quality control and earns customer trust through reliable performance and consistent adherence to high standards. Each component, from the materials chosen to the manufacturing techniques employed, reflects a deep understanding of both traditional mechanics and cutting-edge technology. The result is a product that not only meets but exceeds expectations, delivering safe and effortless steering control for drivers worldwide.

The trustworthiness of a power steering hose manufacturer is often reflected in their adherence to international standards such as ISO 9001 or IATF 16949, certifications that assure quality management practices are upheld. These standards demonstrate a commitment to continuous improvement and customer satisfaction, providing peace of mind to consumers and mechanics alike. Collaboration with automotive manufacturers provides a further layer of authority. Trusted hose suppliers often work directly with vehicle manufacturers to develop bespoke solutions tailored to specific models, ensuring that each hose integrates seamlessly with the vehicle's steering system for optimal performance and longevity. Consumer trust is further bolstered by thorough aftercare services and warranties offered by manufacturers. By offering extended warranties and robust customer service options, manufacturers demonstrate confidence in their products, reassured by their investment in research and development, quality materials, and precision manufacturing techniques. Advanced innovations like electronically-controlled variable assist steering further underscore the importance of high-quality power steering hoses. As automotive technology evolves toward more sophisticated systems, the role of these hoses becomes even more crucial in ensuring that drivers maintain control and safety behind the wheel. In summary, the process of manufacturing power steering hoses blends solid engineering expertise with authoritative quality control and earns customer trust through reliable performance and consistent adherence to high standards. Each component, from the materials chosen to the manufacturing techniques employed, reflects a deep understanding of both traditional mechanics and cutting-edge technology. The result is a product that not only meets but exceeds expectations, delivering safe and effortless steering control for drivers worldwide.

Latest news

-

Understanding Power Steering Tube ReplacementNewsApr.16,2025

-

SAE J1401 Brake Hoses: A Critical Component for Vehicle SafetyNewsApr.16,2025

-

Pipe Couplings: Essential Components for Effective Plumbing and Fluid SystemsNewsApr.16,2025

-

Hose Guard Solutions for Every NeedNewsApr.16,2025

-

Effective Spiral Protection SolutionsNewsApr.16,2025

-

Effective Sewer Cleaning SolutionsNewsApr.16,2025