Creating Custom Power Steering Hoses for Enhanced Vehicle Performance and Reliability

Creating Power Steering Hoses A Comprehensive Guide

Power steering is an essential feature in modern vehicles, allowing drivers to maneuver effortlessly while maintaining control. The heart of this system lies in the power steering hoses, which transport hydraulic fluid from the pump to the steering gear, enabling the power assistance function. In this article, we’ll explore the process of making power steering hoses, outlining the materials, methods, and considerations involved.

Materials Required

To create power steering hoses, manufacturers typically use high-quality materials to ensure durability and efficiency. The primary components include

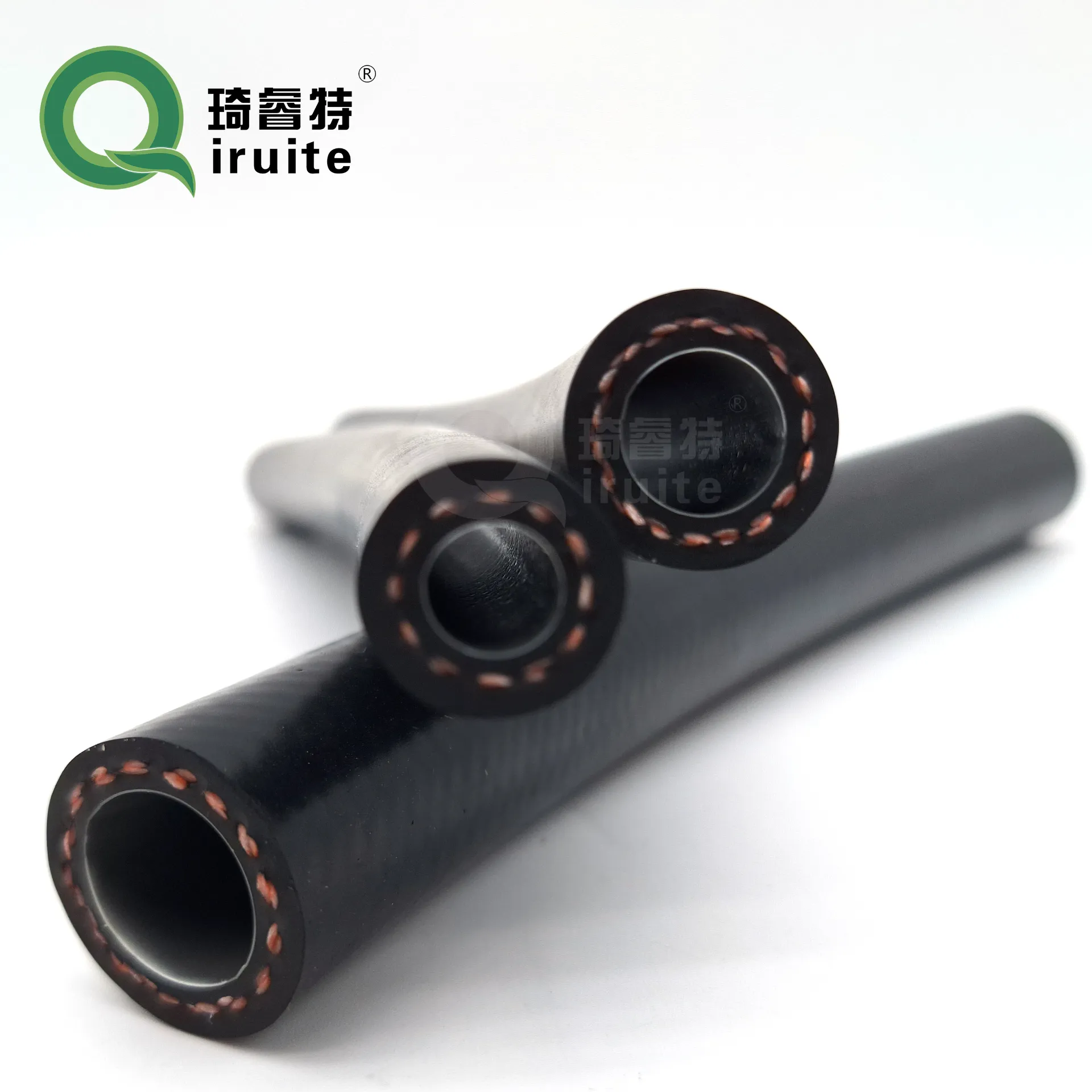

1. Hose Tubing Commonly made from rubber or reinforced synthetic materials, the tubing must withstand high pressure and resist degradation from hydraulic fluid exposure. Synthetic materials like thermoplastic rubber (TPR) or nylon are increasingly popular due to their superior performance and longevity.

2. Fittings Metal fittings, often made from aluminum or steel, are essential for connecting the hoses to the vehicle's power steering system. These fittings need to be precision-engineered to ensure leak-proof connections.

3. Reinforcement Layers In high-pressure applications, hoses may require additional reinforcement to prevent bursting. This is usually achieved through layers of braided steel or other sturdy materials that provide added strength.

4. Sealing Components O-rings and seals are crucial for preventing leaks at the connection points and ensuring the hydraulic system operates efficiently.

Manufacturing Process

The process of making power steering hoses involves several key steps

1. Design and Prototyping

The first step is designing the hose based on the vehicle’s specifications and requirements. Engineers create prototypes to test the fit and functionality within the steering system. Advanced computer-aided design (CAD) software is commonly used to optimize the dimensions and structural integrity of the hoses.

making power steering hoses

2. Cutting and Shaping

Once the designs are finalized, the hose tubing is cut to length. This process involves precise measurements to ensure that each hose fits perfectly within the given space. Tubing may also be shaped or bent to accommodate the layout of the vehicle’s components.

3. Reinforcement Application

If reinforcement is required, additional materials, such as braided steel, are applied to the exterior of the tubing. This is typically done by winding the reinforcement material around the hose and securing it with adhesives or heat, depending on the type of material used.

4. Fitting Installation

After the hoses are shaped and reinforced, the next step is to install the metal fittings. This process often involves crimping, where the fittings are pressed onto the ends of the hoses using specialized machinery. This creates a strong, permanent bond that can withstand the high pressures typically found in power steering systems.

5. Testing

Quality control is paramount in the manufacturing of power steering hoses. Each hose undergoes rigorous testing to ensure it meets industry standards for pressure and durability. This often includes hydraulic pressure testing to identify any potential leaks or weaknesses.

Quality Assurance

Manufacturers must adhere to strict quality assurance protocols throughout the production process. This includes regular inspections, testing of raw materials, and compliance with industry regulations. Certificates of compliance may be issued to ensure that the hoses meet or exceed the necessary safety and performance standards.

Conclusion

Making power steering hoses is a complex process that requires precision engineering and high-quality materials. From the initial design to the final product, every step is crucial for ensuring the performance and safety of the vehicle's steering system. As technology advances, the methods and materials used for manufacturing these hoses continue to evolve, leading to improved reliability and performance in modern automotive applications. Understanding this process is essential for anyone involved in automotive manufacturing or maintenance. Whether you are a professional mechanic, a DIY enthusiast, or simply a car owner interested in how your vehicle operates, knowing the details about power steering hoses can enhance your appreciation for this critical component of automotive engineering.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025