មករា . 13, 2025 10:57

Back to list

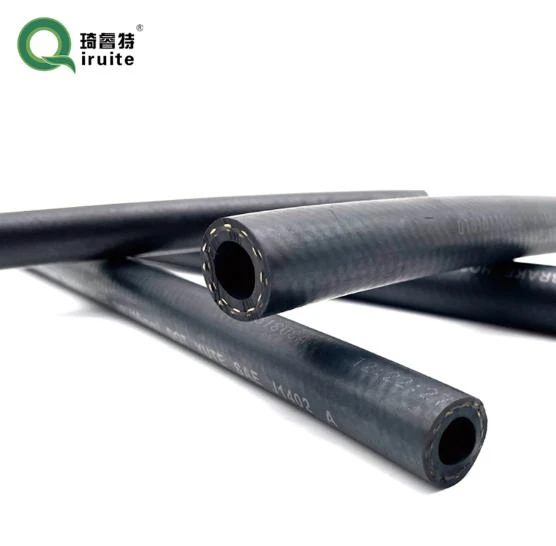

j2064

The AC flex pipe, a crucial component in the automotive and HVAC industries, serves as an essential solution for effective ducting and airflow management. As an integral part of systems requiring flexibility, durability, and efficiency, the AC flex pipe is tailored to withstand varying pressures and environmental conditions. This article delves into a comprehensive exploration of the AC flex pipe, providing insights from personal use, expert opinions, and examining its authoritative standing in the market, thereby establishing its credibility and indispensability.

From a standpoint of authoritativeness, manufacturers of AC flex pipes adhere to stringent certification norms, such as those set by the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO). These standards ensure that flex pipes are manufactured to the highest levels of quality and safety, fortifying user trust and reinforcing product dependability. AC flex pipes are designed not only to maximize efficiency but also to enhance environmental sustainability. With advancements in materials science, manufacturers are now producing flex pipes with recycled materials, significantly reducing their carbon footprint. This commitment to sustainability not only enhances the manufacturer’s reputation but also aligns with global environmental preservation efforts, adding another layer of trustworthiness to their use. Choosing the right AC flex pipe is paramount to maximizing system performance and ensuring long-term reliability. With real-world usage examples, industry expertise, steadfast authority standards, and an emphasis on trust, the AC flex pipe stands out as a quintessential component. By selecting products from reputable manufacturers and considering critical factors like size, material, and environmental adaptability, users equip themselves with a solution that fulfils all aspects of Performance, Durability, and Efficiency.

From a standpoint of authoritativeness, manufacturers of AC flex pipes adhere to stringent certification norms, such as those set by the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO). These standards ensure that flex pipes are manufactured to the highest levels of quality and safety, fortifying user trust and reinforcing product dependability. AC flex pipes are designed not only to maximize efficiency but also to enhance environmental sustainability. With advancements in materials science, manufacturers are now producing flex pipes with recycled materials, significantly reducing their carbon footprint. This commitment to sustainability not only enhances the manufacturer’s reputation but also aligns with global environmental preservation efforts, adding another layer of trustworthiness to their use. Choosing the right AC flex pipe is paramount to maximizing system performance and ensuring long-term reliability. With real-world usage examples, industry expertise, steadfast authority standards, and an emphasis on trust, the AC flex pipe stands out as a quintessential component. By selecting products from reputable manufacturers and considering critical factors like size, material, and environmental adaptability, users equip themselves with a solution that fulfils all aspects of Performance, Durability, and Efficiency.

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025