Hose Connection Techniques for Efficient R134a Refrigerant Handling and Maintenance Practices

Understanding R134a and Its Use in Hose Applications

R134a, or 1,1,1,2-tetrafluoroethane, is a hydrofluorocarbon (HFC) that has gained prominence as a refrigerant, especially in air conditioning systems and refrigeration applications. As environmental concerns regarding ozone depletion have intensified, R134a has emerged as a favored alternative to older refrigerants such as R12, which has been phased out due to its harmful effects on the ozone layer. This article delves into the properties, applications, and hose compatibility of R134a, providing a deeper understanding of its role in modern refrigeration systems.

Properties of R134a

R134a is a colorless, odorless gas at room temperature, and it exhibits excellent thermodynamic properties, making it highly efficient for heat transfer. One of its most notable features is its relatively low global warming potential (GWP) compared to previous refrigerants, which has made it a go-to choice in various cooling applications. R134a operates effectively across a wide range of temperatures, making it versatile for both high and low-temperature refrigeration systems. Its chemical stability ensures that it does not easily break down, further enhancing its reliability in closed-loop systems.

Applications of R134a

R134a is primarily used in automotive air conditioning systems, household refrigerators, and commercial refrigeration equipment. In the automotive industry, it serves as a crucial component in maintaining temperature control within vehicles, ensuring passenger comfort. In household appliances, R134a is integral to the functioning of refrigerators and freezers, where it contributes to food preservation and overall energy efficiency. Furthermore, its application in commercial environments, such as supermarkets and food storage facilities, underscores its importance in the global supply chain.

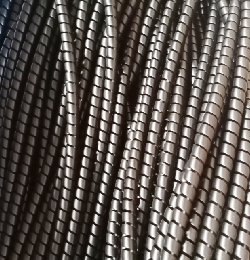

r134a with hose

Hose Compatibility with R134a

When dealing with R134a, the choice of hoses is critical for ensuring system integrity and performance. Hoses used in R134a systems must be manufactured from materials that can withstand the pressure and chemical properties of the refrigerant. Typically, hoses made from rubber composites or specific synthetic materials, such as thermoplastic elastomers, are preferred. These materials provide resistance against the permeation of refrigerants, preventing leaks that could lead to system inefficiency and environmental harm.

It is essential to ensure that hoses meet industry standards set by organizations such as the Society of Automotive Engineers (SAE). For instance, hoses must be rated for the pressures typical of R134a systems, and should show compatibility with R134a to avoid degradation over time. Additionally, the fittings and connections used with R134a hoses should also be resistant to corrosion and should create a leak-proof seal to maintain system pressure.

Conclusion

R134a has played a pivotal role in transforming the refrigeration and air conditioning landscape, serving as a reliable and environmentally friendlier alternative to older refrigerants. Understanding its properties, applications, and the importance of hose compatibility is vital for professionals working in HVAC and refrigeration. As technology continues to evolve, it is crucial to stay informed about the latest developments regarding refrigerants and components used in these systems to ensure optimal performance and adherence to environmental regulations. With its range of applications and growing significance, R134a is likely to remain a key player in the refrigeration industry for the foreseeable future.

-

Understanding Power Steering Tube ReplacementNewsApr.16,2025

-

SAE J1401 Brake Hoses: A Critical Component for Vehicle SafetyNewsApr.16,2025

-

Pipe Couplings: Essential Components for Effective Plumbing and Fluid SystemsNewsApr.16,2025

-

Hose Guard Solutions for Every NeedNewsApr.16,2025

-

Effective Spiral Protection SolutionsNewsApr.16,2025

-

Effective Sewer Cleaning SolutionsNewsApr.16,2025