កុម្ភៈ . 08, 2025 07:40

Back to list

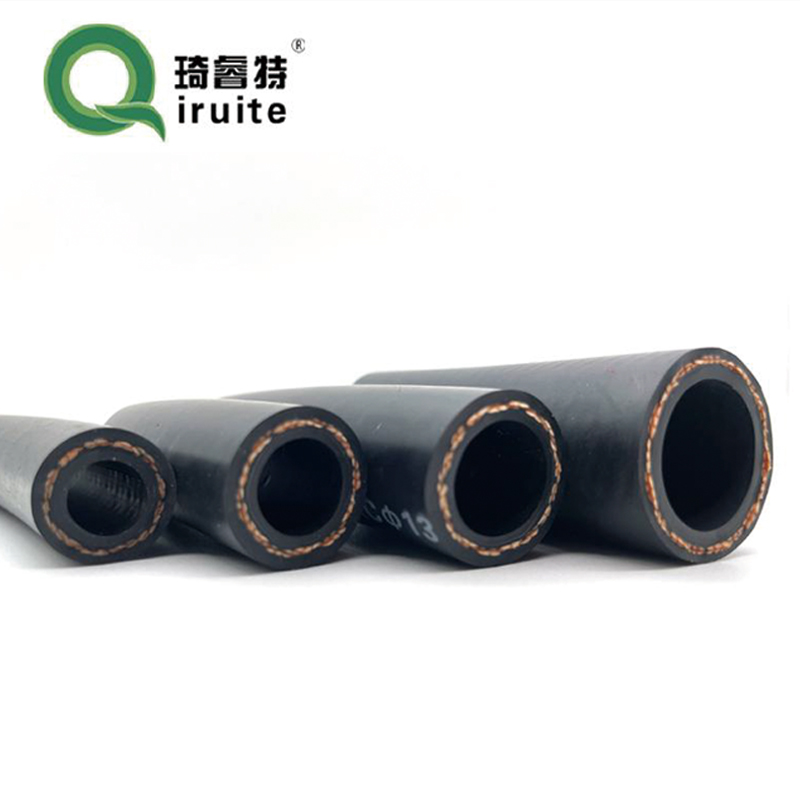

Sewer cleaning hose (sewer cleaning & jetting hose)

Navigating the complex terrain of high-pressure pipe couplings requires an understanding that blends real-world experience with precise technical expertise. In industries ranging from oil and gas to chemical processing, these components are not merely an accessory but a vital component that can drastically impact safety and performance.

Trustworthiness not only involves the technical specifications but also encompasses reliability of service and support. Leading manufacturers provide comprehensive customer support, ensuring that technical guidance is available at every step, from selection to installation and maintenance. This support builds trust, making clients confident that they have a backup in case of any query or mishap. Case studies from major undertakings offer insights into the successful application of high-pressure pipe couplings. In petroleum extraction, for example, companies have successfully deployed these components in challenging offshore environments where pressure and corrosive elements pose significant risks. Feedback from engineers in such cases consistently underscores the importance of precise engineering and quality materials in ensuring system integrity. Further validating the critical role of high-pressure pipe couplings, industry experts often highlight their cost-efficiency over time. By preventing system failures and minimizing maintenance costs, these components provide a substantial return on investment. Correctly installed, they form a robust part of the fluid handling system that requires minimal intervention, which further emphasizes their economic benefit. Emphasizing trustworthiness, experts commonly recommend regular inspections and proactive maintenance as part of a comprehensive pipeline management strategy. It's not just about installing the right coupling but also about ensuring it remains in optimal condition throughout its service life. Advanced diagnostic technologies and routine checks can preemptively identify wear or degradation, thus avoiding unscheduled downtimes. Ultimately, high-pressure pipe couplings represent a significant intersection of engineering excellence and practical application. Their role is essential across multiple sectors and they continue to evolve, integrating new materials and designs that respond to emerging industrial challenges. Professionals leveraging the latest developments in coupling technology often gain a competitive advantage, underscoring their commitment to operational excellence and safety.

Trustworthiness not only involves the technical specifications but also encompasses reliability of service and support. Leading manufacturers provide comprehensive customer support, ensuring that technical guidance is available at every step, from selection to installation and maintenance. This support builds trust, making clients confident that they have a backup in case of any query or mishap. Case studies from major undertakings offer insights into the successful application of high-pressure pipe couplings. In petroleum extraction, for example, companies have successfully deployed these components in challenging offshore environments where pressure and corrosive elements pose significant risks. Feedback from engineers in such cases consistently underscores the importance of precise engineering and quality materials in ensuring system integrity. Further validating the critical role of high-pressure pipe couplings, industry experts often highlight their cost-efficiency over time. By preventing system failures and minimizing maintenance costs, these components provide a substantial return on investment. Correctly installed, they form a robust part of the fluid handling system that requires minimal intervention, which further emphasizes their economic benefit. Emphasizing trustworthiness, experts commonly recommend regular inspections and proactive maintenance as part of a comprehensive pipeline management strategy. It's not just about installing the right coupling but also about ensuring it remains in optimal condition throughout its service life. Advanced diagnostic technologies and routine checks can preemptively identify wear or degradation, thus avoiding unscheduled downtimes. Ultimately, high-pressure pipe couplings represent a significant intersection of engineering excellence and practical application. Their role is essential across multiple sectors and they continue to evolve, integrating new materials and designs that respond to emerging industrial challenges. Professionals leveraging the latest developments in coupling technology often gain a competitive advantage, underscoring their commitment to operational excellence and safety.

Next:

Latest news

-

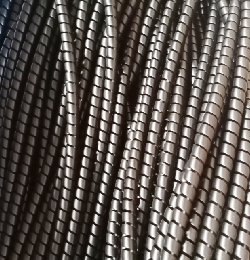

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025