មករា . 09, 2025 12:22

Back to list

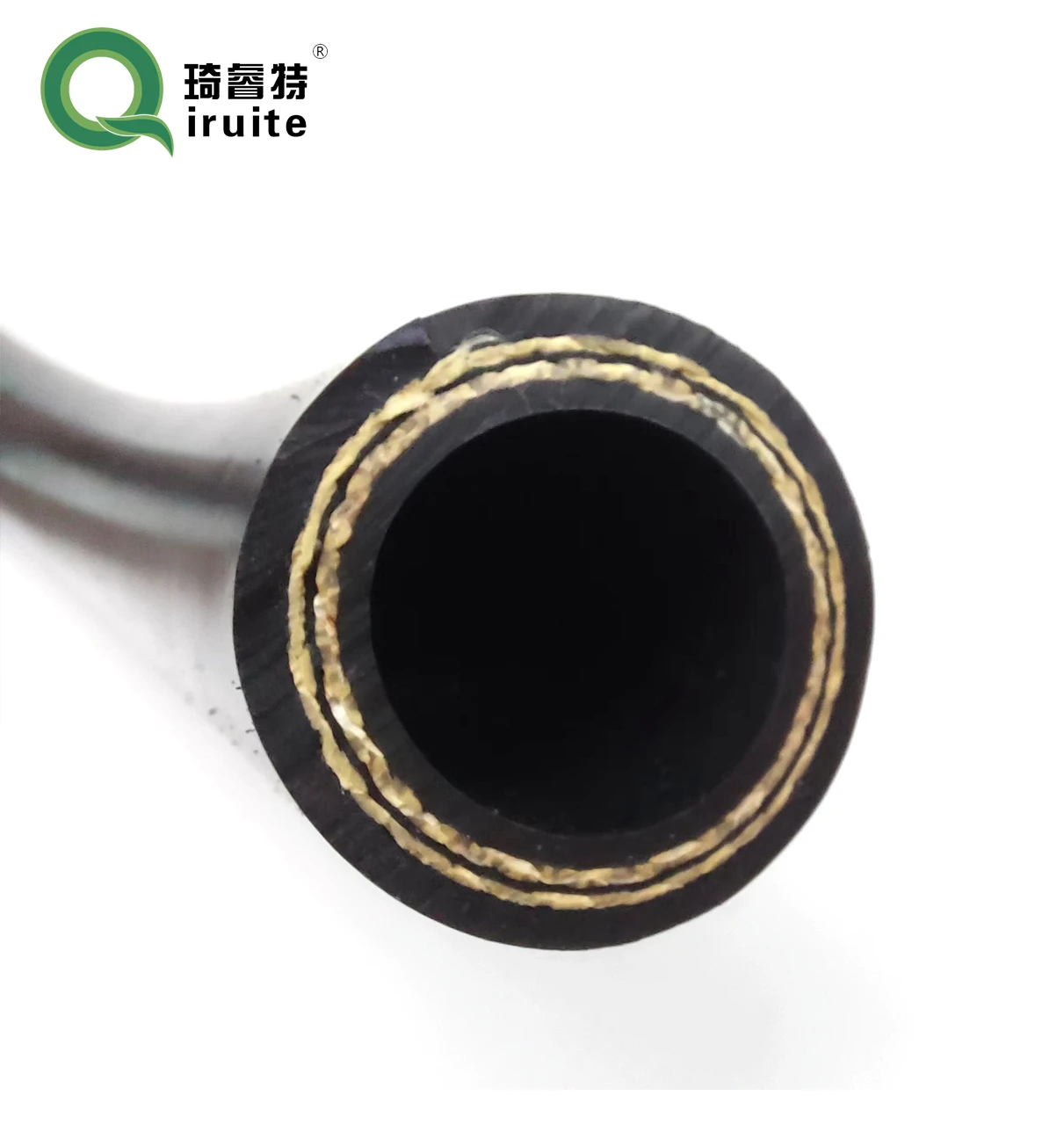

air conditioning pipe

The air conditioning pipe, an often-overlooked component of HVAC systems, is integral to the efficiency, performance, and longevity of the entire setup. This essential component acts as the lifeline of any air conditioning system, facilitating the transportation of refrigerant and ensuring optimal thermal exchange. Drawing from numerous experiences as a professional in HVAC installation and maintenance, this discussion will delve into the intricacies of air conditioning pipes, offering unique insights into their types, materials, and maintenance.

For installations where flexibility is key, synthetic materials like PVC or PEX offer unparalleled versatility. These materials are notably easier to install and adapt to varying layouts, making them ideal for retrofits or complex custom installations. However, they generally underperform in thermal conduction when compared to metal counterparts and might be unsuitable for high-load applications. Proper maintenance of air conditioning pipes is crucial for preventing refrigerant leaks, which can lead to inefficiency or system breakdown. Routine inspections, conducted by certified professionals, should focus on identifying potential weak spots prone to wear or damage. It is highly recommended to engage certified HVAC technicians for regular diagnostics and upkeep, as they bring a wealth of expertise and can provide invaluable advisory on potential enhancements or necessary replacements. In terms of authority and trustworthiness, choosing a reputable brand and ensuring proper installation are vital for maximizing the efficiency and durability of air conditioning pipes. Products from established manufacturers come with rigorous testing standards and certifications, providing peace of mind and assurance of quality. To sum up, the air conditioning pipe might not be the most visible component but is undeniably central to the functionality and efficiency of HVAC systems. Engaging with experienced professionals and selecting the appropriate materials tailored to specific environmental and usage needs ensures not only optimal performance but also extends the lifespan of the air conditioning system. This combination of careful selection, diligent maintenance, and the right expertise elevates the reliability and effectiveness of these crucial systems within both residential and commercial environments.

For installations where flexibility is key, synthetic materials like PVC or PEX offer unparalleled versatility. These materials are notably easier to install and adapt to varying layouts, making them ideal for retrofits or complex custom installations. However, they generally underperform in thermal conduction when compared to metal counterparts and might be unsuitable for high-load applications. Proper maintenance of air conditioning pipes is crucial for preventing refrigerant leaks, which can lead to inefficiency or system breakdown. Routine inspections, conducted by certified professionals, should focus on identifying potential weak spots prone to wear or damage. It is highly recommended to engage certified HVAC technicians for regular diagnostics and upkeep, as they bring a wealth of expertise and can provide invaluable advisory on potential enhancements or necessary replacements. In terms of authority and trustworthiness, choosing a reputable brand and ensuring proper installation are vital for maximizing the efficiency and durability of air conditioning pipes. Products from established manufacturers come with rigorous testing standards and certifications, providing peace of mind and assurance of quality. To sum up, the air conditioning pipe might not be the most visible component but is undeniably central to the functionality and efficiency of HVAC systems. Engaging with experienced professionals and selecting the appropriate materials tailored to specific environmental and usage needs ensures not only optimal performance but also extends the lifespan of the air conditioning system. This combination of careful selection, diligent maintenance, and the right expertise elevates the reliability and effectiveness of these crucial systems within both residential and commercial environments.

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025