7 8 pipe coupling

Understanding 7 8 Pipe Coupling A Guide

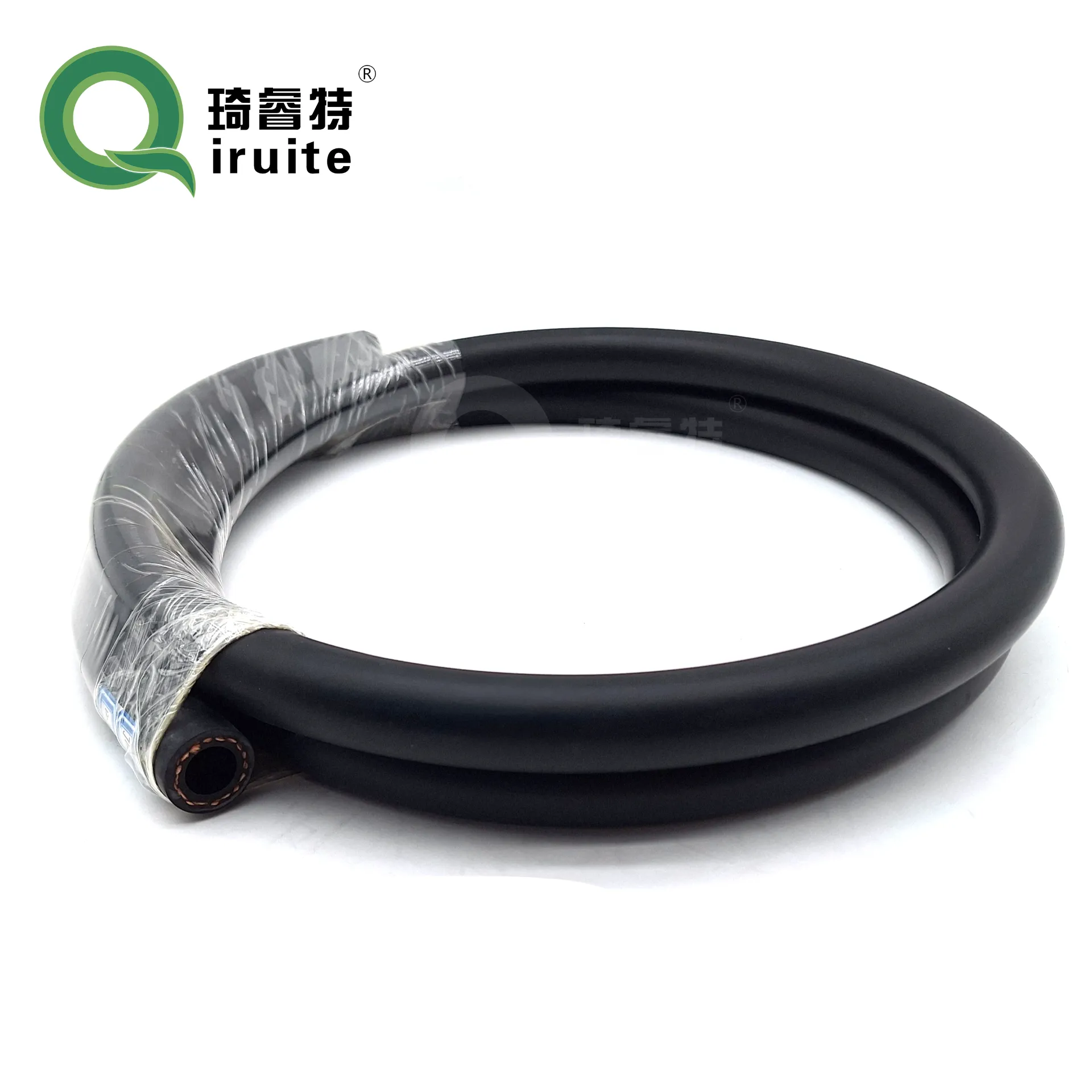

In the realm of plumbing and pipeline construction, the importance of high-quality fittings cannot be overstated. One such fitting is the pipe coupling, specifically one designed to meet the criteria of 7 8% pipe coupling. This term refers to a specific size and thread type used in various piping systems.

What is Pipe Coupling?

A pipe coupling is a mechanical device that connects two pieces of pipe together. It can serve as an extension, allowing for the seamless joining of pipes that may be of the same or different diameters. The pipeline infrastructure relies on couplings to ensure that the flow of liquids or gases is uninterrupted. They can be made from various materials such as metals, plastics, and composites to suit different application needs.

The Specifications of 7 8% Couplings

The designation 7 8% indicates specific measurements or specifications for a coupling. To delve deeper into the specifics, the numbers typically refer to the pipe size and corresponding fittings. For instance, the first number (7) might denote a nominal pipe size, while the second number (208) could specify the type of threading or pressure rating.

These couplings are often used in situations requiring a robust and leak-proof connection, such as in water supply systems, gas pipelines, and even in industrial applications. They are designed to withstand significant pressure and prevent any form of leakage, making them crucial in maintaining the integrity of the entire piping system.

Types of Pipe Couplings

There are several types of pipe couplings available, each serving a unique purpose. Here are some common types relevant to the 7 8% specifications

7 8 pipe coupling

1. Rigid Couplings These are designed for permanent connections where flexibility is not needed. They provide strong and robust connections, ideal for situations where the pipes will not experience movement.

2. Flexible Couplings These allow for a small degree of movement between the joined pipes, making them suitable for areas where thermal expansion can occur.

3. Reducing Couplings These are used to connect pipes of differing diameters. They come in handy in systems where transitions between pipe sizes are necessary.

4. Compression Couplings These fittings enable a secure connection through compression, which can be advantageous in situations requiring frequent disassembly and reassembly.

Applications of 7 8% Couplings

The applications for pipe couplings running under the 7 8% specifications are vast. They can be found in residential plumbing systems for connecting pipes under sinks or in bathrooms. In industrial settings, they are vital for connecting larger pipes used in transporting water, oil, or chemicals.

Moreover, the compatibility of 7 8% couplings with different materials and sizes makes them versatile for various engineering applications. Environments such as oil and gas exploration, manufacturing plants, and even agricultural irrigation systems often rely on these couplings for optimal performance and safety.

Conclusion

The effective utilization of 7 8% pipe coupling is essential for any piping system aiming for efficiency and reliability. As industries vary in their demands, understanding the specifications and types of couplings allows for informed decisions when designing or maintaining a piping network. As technology continues to evolve, so too will the materials and designs of pipe couplings, further enhancing their capacity to meet modern engineering challenges. By investing in high-quality pipe couplings, companies can ensure longevity and safety in their piping infrastructure.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025