កុម្ភៈ . 03, 2025 02:49

Back to list

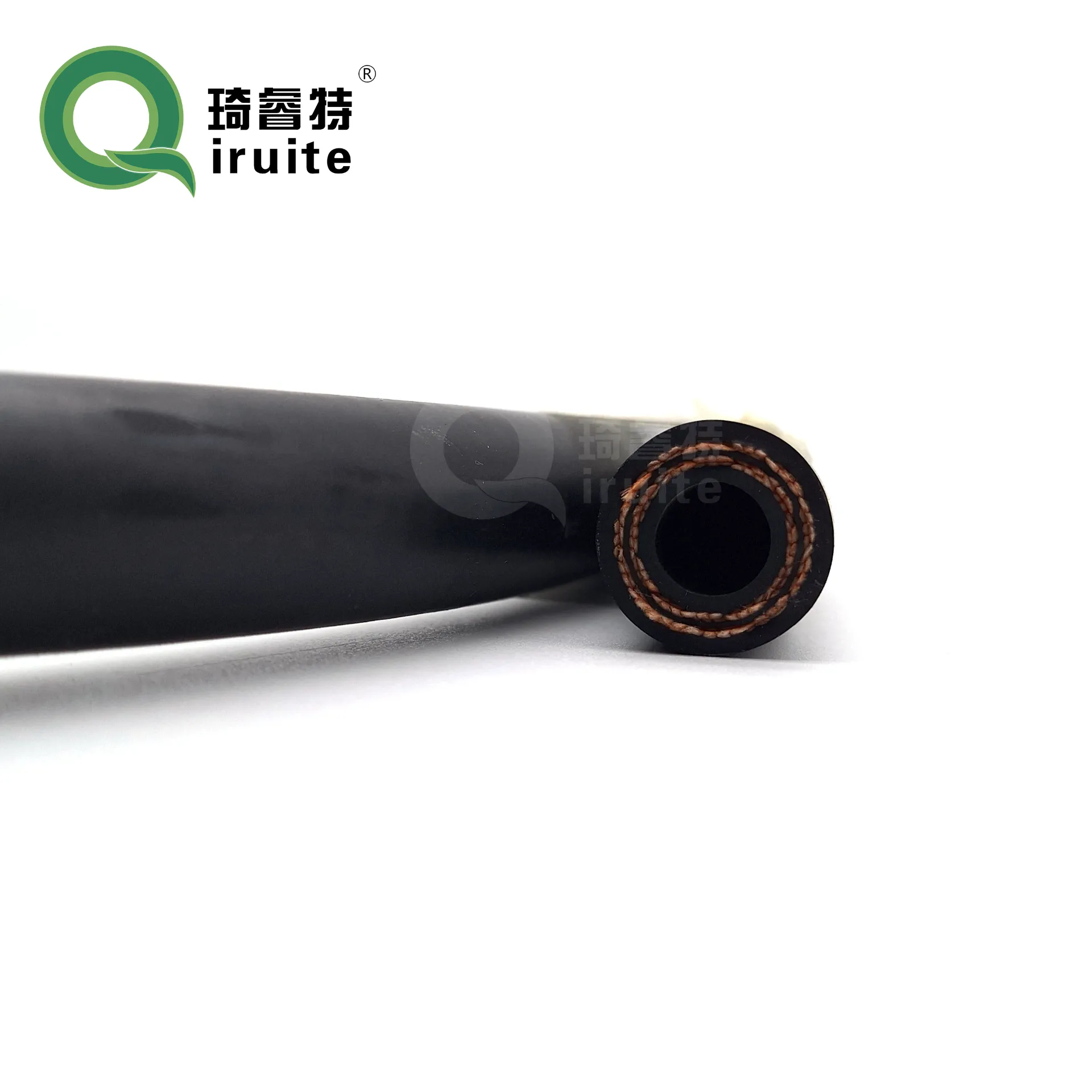

sae j2064

When it comes to enhancing the longevity and efficiency of industrial systems, the choice of components like 3 4 steel couplings plays a pivotal role. These couplings are essential for applications that require robustness and precise alignment, especially in heavy-duty frameworks where reliability is non-negotiable.

From an authoritativeness standpoint, the endorsement of 3 4 steel couplings comes from extensive case studies and technical whitepapers authored by industry experts. These documents underscore how critical these components are in optimizing the lifespan and performance of industrial machines. Such literature is indispensable for engineers and procurement specialists who prioritize reliability and sustainability in their projects. Trustworthiness is another cornerstone of the 3 4 steel coupling's reputation. Manufacturers of these couplings adhere to stringent quality control measures and international standards, ensuring consistency and integrity in every piece produced. As someone deeply embedded in the industrial procurement scene, the persistent reliability of these couplings is evident through numerous user testimonials and long-term client satisfaction. In essence, the adoption of 3 4 steel couplings is a testament to a commitment to quality and efficiency. For industries aiming to achieve optimal mechanical performance and operational excellence, investing in these couplings is a strategic decision. As the field evolves, the demands placed on industrial components will only increase, and the choice of materials like 3 4 steel will continue to play a crucial role in meeting those challenges head-on.

From an authoritativeness standpoint, the endorsement of 3 4 steel couplings comes from extensive case studies and technical whitepapers authored by industry experts. These documents underscore how critical these components are in optimizing the lifespan and performance of industrial machines. Such literature is indispensable for engineers and procurement specialists who prioritize reliability and sustainability in their projects. Trustworthiness is another cornerstone of the 3 4 steel coupling's reputation. Manufacturers of these couplings adhere to stringent quality control measures and international standards, ensuring consistency and integrity in every piece produced. As someone deeply embedded in the industrial procurement scene, the persistent reliability of these couplings is evident through numerous user testimonials and long-term client satisfaction. In essence, the adoption of 3 4 steel couplings is a testament to a commitment to quality and efficiency. For industries aiming to achieve optimal mechanical performance and operational excellence, investing in these couplings is a strategic decision. As the field evolves, the demands placed on industrial components will only increase, and the choice of materials like 3 4 steel will continue to play a crucial role in meeting those challenges head-on.

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025