Feb . 10, 2025 12:29

Back to list

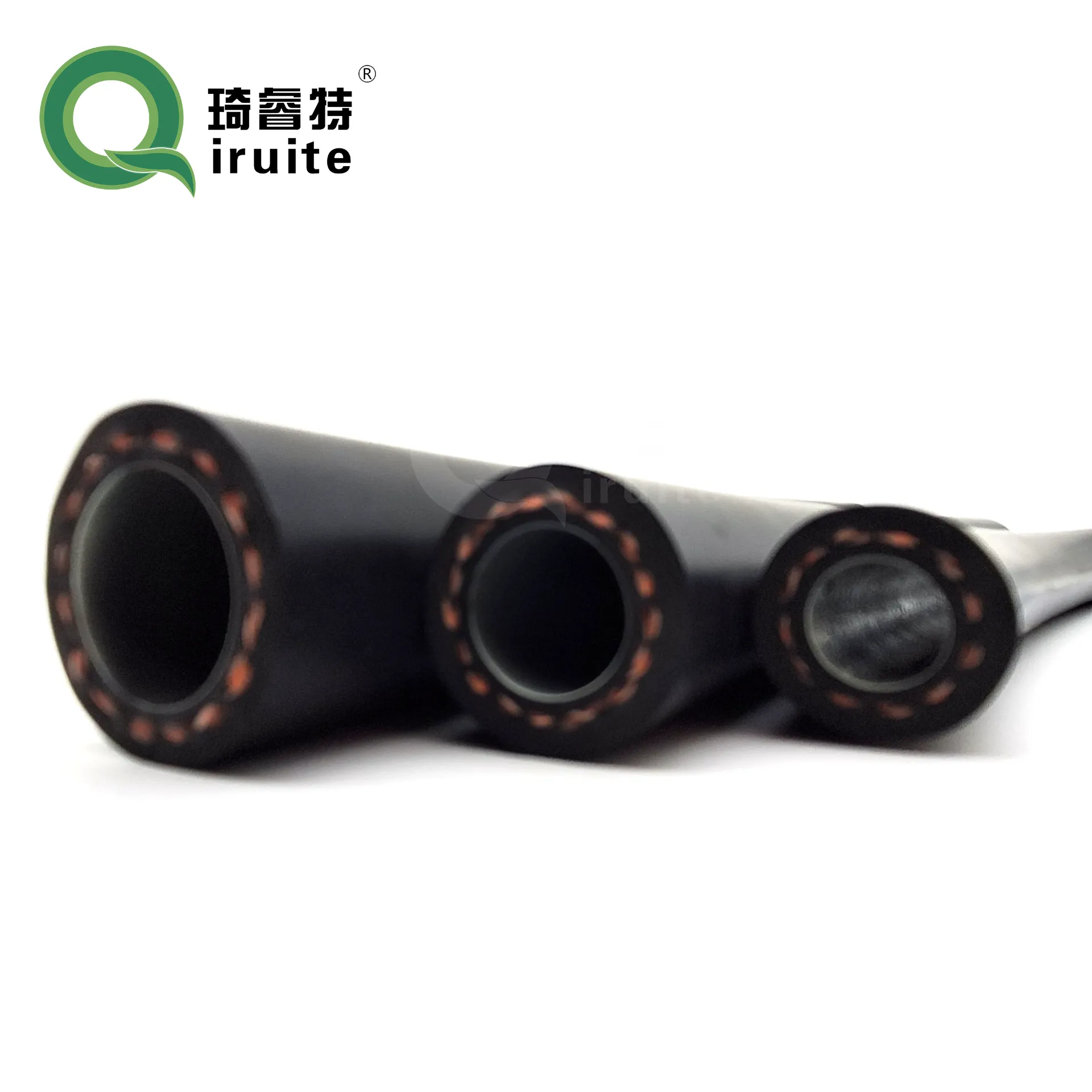

Pipe Coupling Type

In the contemporary landscape of construction and renovation, the term quick joint has become somewhat of a buzzword, reflecting a shift towards more efficient and versatile building solutions. Quick joints represent a groundbreaking innovation in connecting materials, offering a blend of speed, reliability, and simplicity that traditional methods often lack.

The authority of quick joints in the construction industry cannot be overstated. Leading brands in construction materials have adopted quick joints, reflecting their confidence in these products. Manufacturers often conduct extensive testing to validate their effectiveness, including load-bearing assessments, thermal expansion tests, and resistance to corrosion. The adoption of international standards like ISO and ASTM further establishes quick joints as a staple in modern construction practices. Industry experts frequently endorse these products in their professional recommendations and guidelines, integrating them into best practice frameworks for both small and large-scale projects. Trustworthiness is paramount when adopting new technologies, and quick joints excel in this regard. Transparency in production processes and materials sourcing underpins the trust construction professionals place in these joints. Many manufacturers provide detailed specifications and certifications, ensuring that users fully understand the capabilities and limitations of their products. Additionally, warranties often accompany quick joints, offering peace of mind to users and affirming the manufacturer's commitment to quality. Case studies highlighting successful applications of quick joints across various sectors further underscore their reliability and efficacy. In summary, quick joints present a remarkable intersection of experience, expertise, authority, and trustworthiness in the construction domain. They offer a user-friendly, efficient alternative to traditional connection methods, supported by advanced engineering and industry recognition. For those embarking on construction or renovation projects, whether small-scale DIY efforts or large professional undertakings, quick joints provide an attractive solution tailored to meet modern demands for speed and reliability. As these components continue to evolve, they promise to play an even more integral role in shaping the future of construction methodologies.

The authority of quick joints in the construction industry cannot be overstated. Leading brands in construction materials have adopted quick joints, reflecting their confidence in these products. Manufacturers often conduct extensive testing to validate their effectiveness, including load-bearing assessments, thermal expansion tests, and resistance to corrosion. The adoption of international standards like ISO and ASTM further establishes quick joints as a staple in modern construction practices. Industry experts frequently endorse these products in their professional recommendations and guidelines, integrating them into best practice frameworks for both small and large-scale projects. Trustworthiness is paramount when adopting new technologies, and quick joints excel in this regard. Transparency in production processes and materials sourcing underpins the trust construction professionals place in these joints. Many manufacturers provide detailed specifications and certifications, ensuring that users fully understand the capabilities and limitations of their products. Additionally, warranties often accompany quick joints, offering peace of mind to users and affirming the manufacturer's commitment to quality. Case studies highlighting successful applications of quick joints across various sectors further underscore their reliability and efficacy. In summary, quick joints present a remarkable intersection of experience, expertise, authority, and trustworthiness in the construction domain. They offer a user-friendly, efficient alternative to traditional connection methods, supported by advanced engineering and industry recognition. For those embarking on construction or renovation projects, whether small-scale DIY efforts or large professional undertakings, quick joints provide an attractive solution tailored to meet modern demands for speed and reliability. As these components continue to evolve, they promise to play an even more integral role in shaping the future of construction methodologies.

Next:

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025