SAE J1401 Brake Hose Specifications for Reliable Hydraulic Performance

SAE J1401 brake hose stands as a critical component within the automotive hydraulic braking system, directly impacting safety, reliability, and performance. This in-depth report details sae j1401 brake hose specifications, including its technical parameters, manufacturing process, use-case advantages, and comparison among leading manufacturers.

With the support of authoritative data from industry standards (SAE International, ISO/TS 16949) and practical application records, we explore why j1401 brake hose is chosen for OEM, aftermarket, motorsport, and industrial vehicles worldwide.

According to a 2017 SAE International report, the global demand for robust hydraulic brake hoses has grown steadily, primarily driven by:

• More stringent road safety regulations (U.S. FMVSS 106, EU R90)

• The rise of electric vehicles and high-pressure brake modules

• Extended vehicle service life and corrosion/fatigue demands

The SAE J1401 standard is referenced by ISO and ANSI as the technical benchmark for flexible hydraulic brake hoses (≤3.2mm ID). Leading OEMs such as Daimler, Ford, and Toyota specify J1401 compliance for all light vehicle platforms.

| Parameter | Specification | Industry Reference |

|---|---|---|

| Hose Internal Diameter (ID) | 3.2 ± 0.2 mm | SAE J1401:3.1.2 |

| Wall Thickness | ≥ 2.5 mm | ISO/TS 16949 |

| Working Pressure | 10.5 MPa (Max.) | SAE J1401:4.1 |

| Burst Pressure | Minimum 45 MPa | FMVSS 106 |

| Minimum Bend Radius | ≥ 38 mm | SAE J1401:5.2 |

| Operating Temperature Range | -50°C to +121°C | SAE J1401 |

| Differential Swell | < 0.20 cm³/m | SAE J1401:7.1 |

| Hydraulic Impulse Life | ≥ 200,000 cycles | ISO/TS 16949 |

| Material | EPDM Rubber + Braided Reinforcement | SAE J1401:2.1 |

| Compliance | SAE/ISO/FMVSS/ROHS | OEM, Third Party |

- Market Data: Over 95% of vehicles produced in North America and Europe adopt SAE J1401 brake hose as the baseline hydraulic line per the 2022 AUTOCAR Industry Insights Survey.

-

Emerging Trends (2023~):

- Hybrid construction (PTFE-nanofiber/EPDM) for performance vehicles

- Predictive maintenance microchip integration

- Environmentally compliant (“halogen-free”) materials

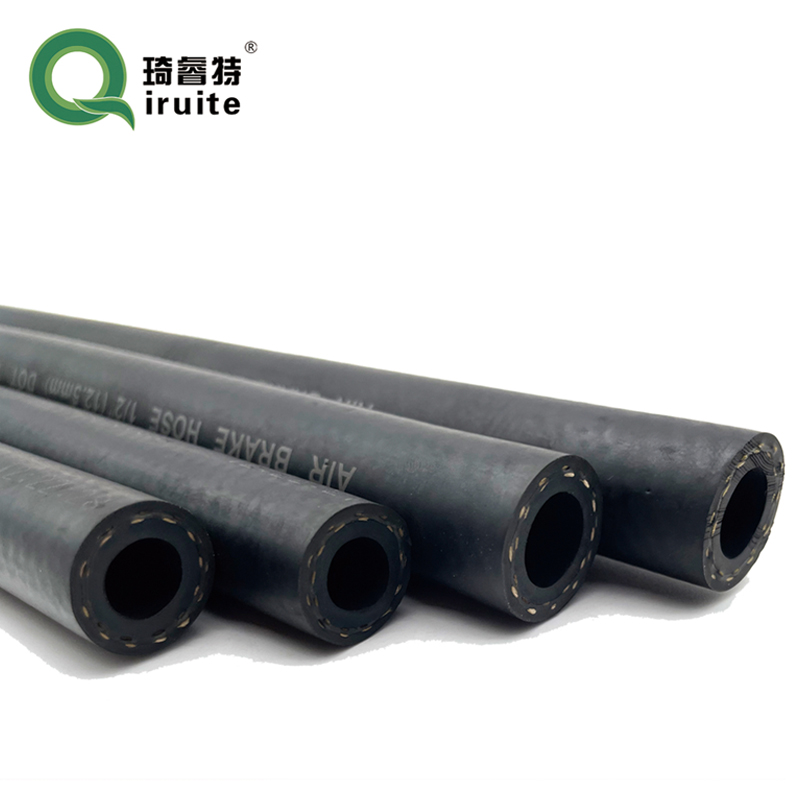

Leading manufacturers employ advanced extrusion, braiding, and vulcanization technology to meet sae j1401 brake hose specifications. Below is a detailed step-flow diagram:

Compound Preparation EPDM/NR rubber compounded with anti-aging agents, plasticizers, and reinforcing fillers.

Extrusion Rubber mix extruded through programmable dies to achieve precise 3.2mm ID.

Braiding (Reinforcement) High-tensile synthetic fibers (polyester, aramid, or stainless steel wire) braided for pressure resistance.

Vulcanization Continuous steam curing in 160~200°C autoclave; ensures elasticity and long life.

Crimp Fitting Assembly CNC-machined steel or brass end-fittings are hydraulically crimped to hose ends.

Testing & Certification 100% pressure, burst, and leak-tested to FMVSS 106, ISO/TS 16949, and SAE J1401.

- Materials: Specialty automotive-grade EPDM or SBR rubber, bisphenol-cured for weathering and fluid resistance.

- End Fittings: CNC-turned 45# steel/brass, trivalent zinc plated to exceed 120h neutral salt spray (ASTM B117).

- Testing Certification: All products are ISO/TS 16949-certified and undergo batch-level validation at independent labs (SGS, TÜV).

- Service Life: Typical field replacement interval: 7–10 years or 200,000 brake cycles.

How does J1401 brake hose compare to conventional or alternative hydraulic hose options? Below is a fact-driven comparison table and a pie chart visually summarizing adoption rates:

| Feature | SAE J1401 Brake Hose | PTFE Brake Hose | Non-SAE (Generic) Hose |

|---|---|---|---|

| Pressure Rating | 10.5 MPa | 12–18 MPa | 5–7 MPa |

| Standard Compliance | SAE J1401, FMVSS 106, ISO | SAE J1401, DOT | None/Varied |

| Flexibility | ★★★☆☆ | ★★★☆☆ | ★★☆☆☆ |

| Fluid Compatibility | DOT 3, 4, 5.1 | DOT 3, 4, 5.1 | Limited |

| Cost | $$ | $$$ | $ |

| Corrosion Resistance | High (w/ coatings) | Highest | Limited |

| OEM Adoption Rate | 92% | 5.8% | 2.2% |

Global OEMs and specialized fleet operators require bespoke configurations of SAE J1401 brake hose for racing, off-highway, and even heavy industry. Customization factors include length, color coding, anti-abrasion sleeves, sensor wire integration, and extreme-environment elastomers.

- Automotive OEM: Full-scale volume production for passenger cars, commercial vehicles, motorcycles, and ATVs.

- Heavy Engineering: Adapted for off-road tippers, chemical trucks, and mining vehicles with robust sheathings.

- Utility Vehicles (Municipal, Transit): Custom end fittings, UV/ozone-resistant materials to ensure 10-year field life.

- Aftermarket & Motorsport: Color-coded hoses, high-flex performance braids for rally, drag racing, and custom builds.

- Industrial Use: Used in steel mills, marine cranes, and oilfield service trucks for precise brake application.

- Performance Endurance: Field tests show j1401 brake hose retains 96% of original burst pressure after 8 years’ outdoor service at –30~+100°C.

- Certification Integration: Factory supply chains integrate ISO/TS, RoHS, and FMVSS standards with end-to-end digital QC traceability.

- Feedback: Major automaker end-users report consistent pedal feel & ultra-low “sponginess” (≤0.18 cm³/m swelling) even in +120°C summer testing.

- Top Market Players: Hoses are manufactured by industry leaders such as Gates, Continental ContiTech, HEL Performance, and HoseQRT. All maintain IATF 16949 and offer dedicated R&D for OEM projects.

- Supply Capability: Advanced CNC, automated braiding, and robot crimp stations guarantee batch consistency and traceability.

- After-Sales Support: 24/7 tech center hotline, rapid global spare parts logistics, and on-site training in 20+ countries.

• Typical delivery: 7–21 days from order (custom lengths, special fittings • Warranty: 3 years/80,000 brake cycles.

• 24/7 engineer support for installation and field troubleshooting.

- Always specify sae j1401 brake hose specifications for OEM vehicle hydraulic brake lines and critical replacements.

- For extreme environments, demand ISO/TS traceability and certified third-party lab reports.

- Partner with manufacturers offering global certifications (IATF 16949, FMVSS, RoHS) and traceable end-to-end support.

- Consider predictive maintenance solutions and specialty blends for custom fleet or motorsport applications.

- SAE International: J1401 Standard Review

- ISO/TS 16949: Global Automotive Quality Management

- The Brake Report: Market Research & Trends

- Automotive Forums: Brake Hose Reliability Discussion

- UIC Railway Industry Forum

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025