Jan . 25, 2025 01:09

Back to list

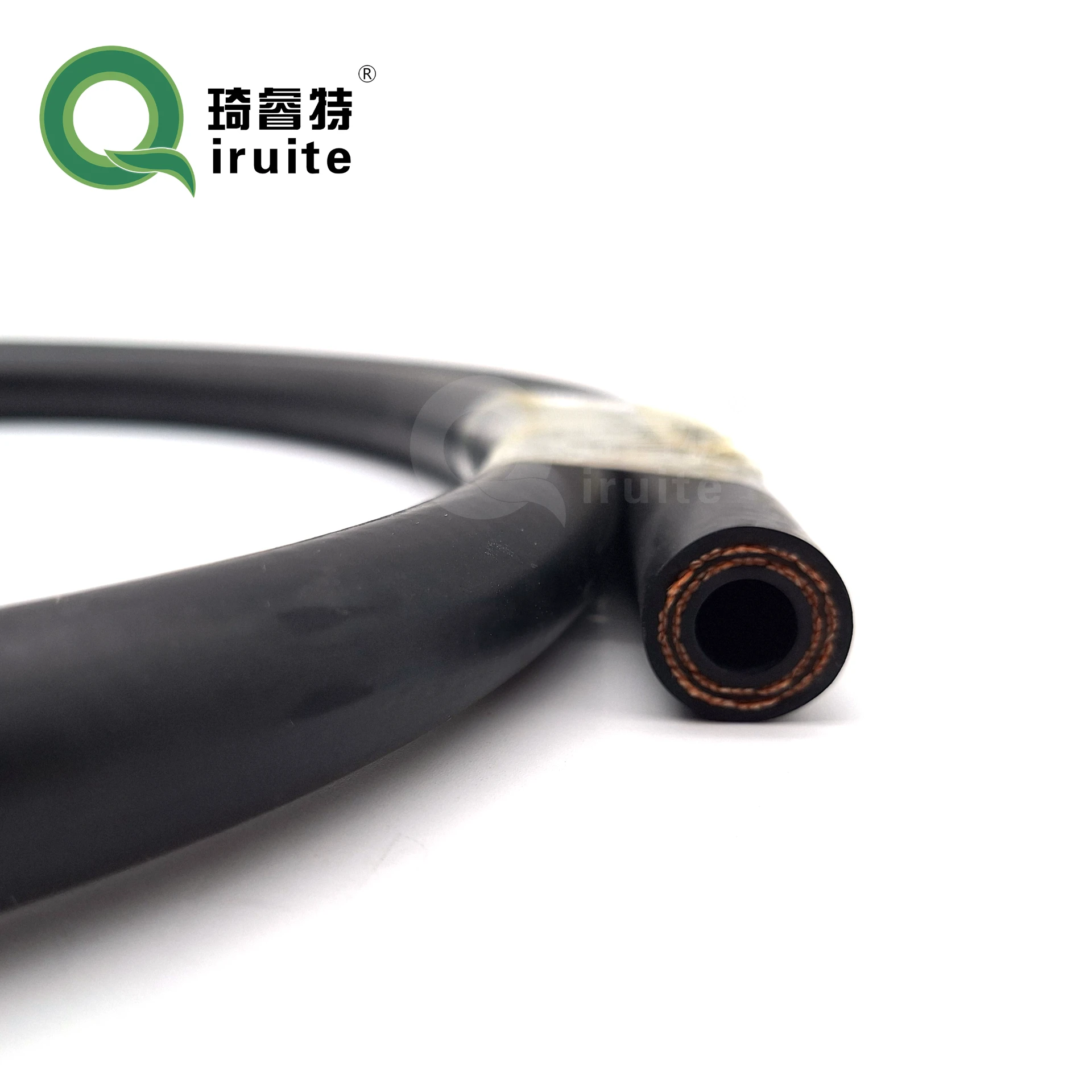

pipe coupling joint

Pipe coupling joints are a critical component in various industrial applications, ensuring the secure connection of pipes and enabling seamless flow across systems. Despite their ubiquitous presence in industries like plumbing, construction, and oil & gas, the choice of the right pipe coupling can significantly impact operational efficiency and reliability. Drawing from decades of hands-on experience and deep-seated expertise, our exploration into pipe coupling joints unveils the profound impact these mechanical marvels hold, backed by authoritative insights and trusted methodologies.

Authoritative sources within industry circles often highlight advancements in coupling technologies that enhance performance. Recent innovations include self-repairing couplings that utilize smart materials capable of responding dynamically to minor disruptions or corrosion, thus extending the service life of the pipe systems they inhabit. Such advancements demand continuous professional development and staying abreast of current research to advise optimal solutions reliably. Trustworthiness in information regarding pipe coupling joints is non-negotiable, particularly as it pertains to safety. Industry guidelines and stringent testing protocols govern the manufacture and application of coupling joints. The stamp of certification from recognized bodies assures end-users about the product's competency in delivering under specified conditions. Real-world case studies often serve as validation, sharing empirical data on coupling performance in critical environments such as underwater pipelines or high-altitude installations. In conclusion, the selection and application of pipe coupling joints command a blend of experienced insight, specialized knowledge, authoritative guidance, and trustworthy practices. Whether addressing the needs of a high-pressure system or adapting to the dynamic requirements of a new installation, the role of pipe coupling joints in ensuring operational continuity cannot be overstated. By employing a strategy rooted in comprehensive understanding and cutting-edge innovation, industry professionals can harness these components to optimize system performance while minimizing risks. Adopting a proactive approach ensures that every coupling joint employed not only meets immediate requirements but is also positioned to serve efficiently over the long term, reflecting a commitment to excellence and holistic system integrity.

Authoritative sources within industry circles often highlight advancements in coupling technologies that enhance performance. Recent innovations include self-repairing couplings that utilize smart materials capable of responding dynamically to minor disruptions or corrosion, thus extending the service life of the pipe systems they inhabit. Such advancements demand continuous professional development and staying abreast of current research to advise optimal solutions reliably. Trustworthiness in information regarding pipe coupling joints is non-negotiable, particularly as it pertains to safety. Industry guidelines and stringent testing protocols govern the manufacture and application of coupling joints. The stamp of certification from recognized bodies assures end-users about the product's competency in delivering under specified conditions. Real-world case studies often serve as validation, sharing empirical data on coupling performance in critical environments such as underwater pipelines or high-altitude installations. In conclusion, the selection and application of pipe coupling joints command a blend of experienced insight, specialized knowledge, authoritative guidance, and trustworthy practices. Whether addressing the needs of a high-pressure system or adapting to the dynamic requirements of a new installation, the role of pipe coupling joints in ensuring operational continuity cannot be overstated. By employing a strategy rooted in comprehensive understanding and cutting-edge innovation, industry professionals can harness these components to optimize system performance while minimizing risks. Adopting a proactive approach ensures that every coupling joint employed not only meets immediate requirements but is also positioned to serve efficiently over the long term, reflecting a commitment to excellence and holistic system integrity.

Next:

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025