metal hose guard

Understanding Metal Hose Guards Protection and Durability

Metal hose guards are essential components in various industrial and commercial applications, designed to protect hoses from environmental wear and tear while enhancing safety. These protective coverings are engineered to mitigate damage to hoses caused by abrasion, impact, and extreme temperatures, making them vital in industries such as manufacturing, construction, and mining.

The Importance of Hose Protection

Hoses are pivotal in transferring fluids, gases, and other materials in countless applications. However, they are often exposed to harsh conditions, such as sharp edges, heavy machinery, and abrasive surfaces. This exposure can lead to premature wear, leaks, or even catastrophic failures. Metal hose guards act as a robust barrier, shielding hoses from physical damage, which can extend their operational lifespan and reduce maintenance costs.

Materials and Design

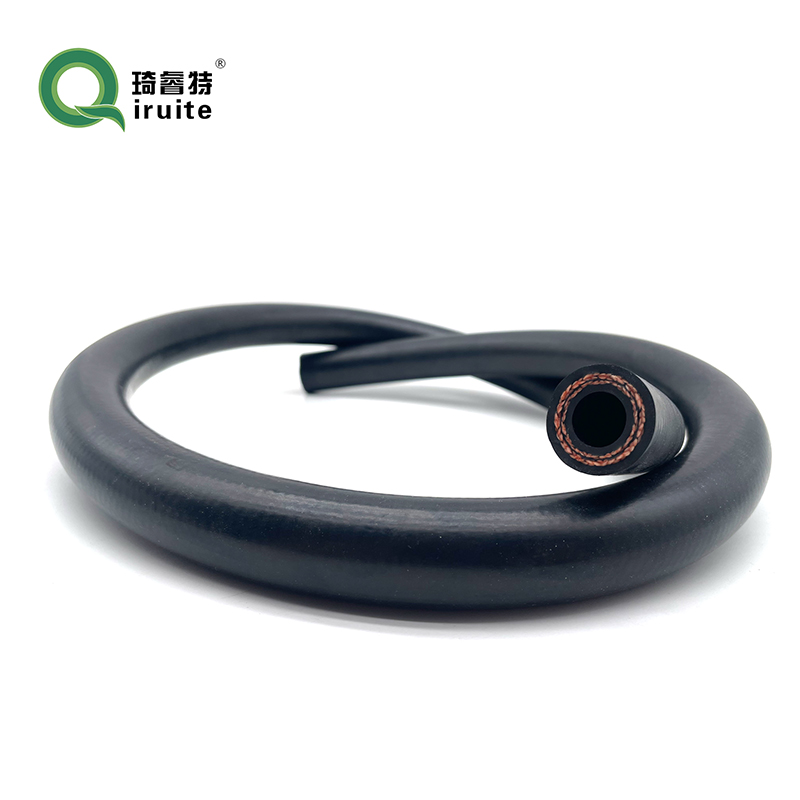

Typically constructed from durable materials like stainless steel or galvanized steel, metal hose guards are engineered to withstand various environmental factors. Stainless steel is particularly favored for its corrosion resistance, making it ideal for industries dealing with chemicals or moist environments. The design of these guards often incorporates features such as spiral wrapping or protective sleeves, which enhance their ability to absorb shocks and disperse impact forces.

Moreover, metal hose guards can be designed for specific applications. For example, heavy-duty models are used in mining operations where hoses might come into contact with sharp rocks and debris, whereas lighter models might be adequate for less abrasive environments.

Safety Benefits

metal hose guard

In addition to protecting hoses, metal hose guards contribute significantly to workplace safety

. By preventing hose damage, they also minimize the risk of spills and leaks, which can pose safety hazards such as slips or chemical exposure. The presence of a hose guard alerts employees to the potential risks associated with hoses, encouraging them to practice caution when moving near these areas.Furthermore, metal hose guards can be equipped with warning signs and labels, enhancing visibility and reminding workers to adhere to safety protocols. This added layer of security is crucial in maintaining a safe working environment, particularly in industries where heavy machinery and high-pressure systems are common.

Installation and Maintenance

Installing metal hose guards is generally a straightforward process, but proper installation is crucial for maximizing their protective capabilities. It’s important to ensure that the guards fit snugly around the hoses and are secured to prevent movement during operation. Regular inspections should also be conducted to identify any signs of wear or damage to the guards themselves, as well as the hoses they protect.

Maintenance of metal hose guards involves cleaning to remove debris and corrosion, which can be particularly important in environments exposed to harsh chemicals or saltwater. A well-maintained guard can effectively extend the life of the hose and ensure ongoing protection.

Conclusion

In conclusion, metal hose guards play a vital role in the longevity and safety of hose operations across various industries. Their ability to protect hoses from physical damage, reduce maintenance costs, and enhance workplace safety makes them an indispensable component in any setting where hoses are utilized. Investing in high-quality metal hose guards can lead to significant long-term benefits, making them an essential consideration for businesses aiming to optimize their operations and ensure the safety of their workforce.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025