PTFE Power Steering Hose Durable, High-Performance Solution

- The Unmatched Technical Advantages of PTFE Power Steering Hoses

- Material Properties: Why PTFE Outperforms Conventional Materials

- Leading Manufacturers and Product Specifications Comparison

- Custom Solutions for Diverse Applications

- Real-World Success Stories in Commercial and Racing Applications

- Installation Guidelines and Long-Term Performance Metrics

- Future Outlook for PTFE Power Steering Hose Technology

(ptfe power steering hose)

The Unmatched Technical Advantages of PTFE Power Steering Hoses

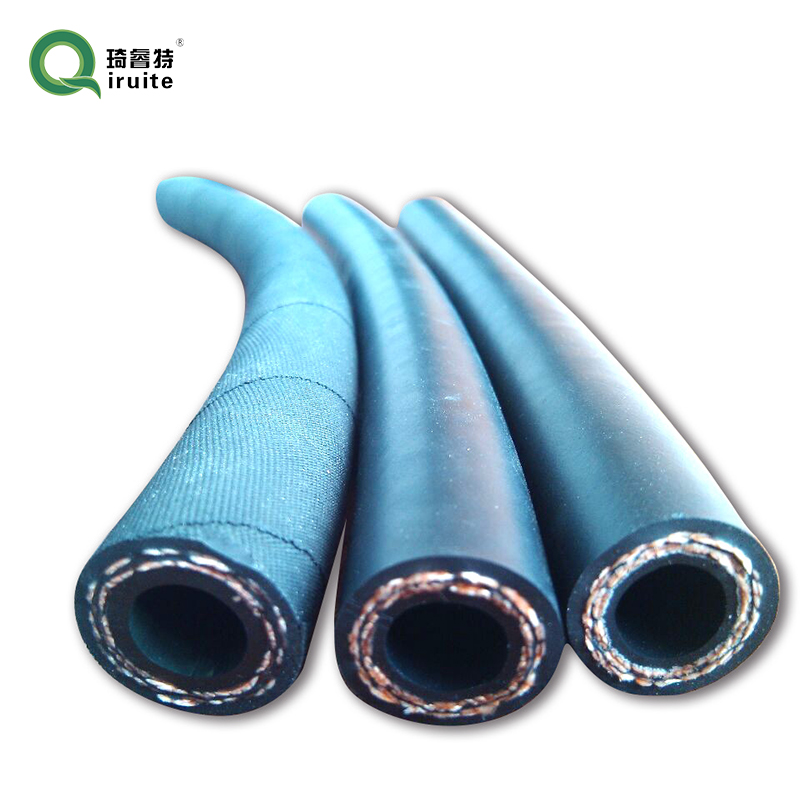

PTFE power steering hoses represent a revolutionary advancement in automotive fluid transfer systems. Unlike traditional rubber hoses, these engineering marvels utilize polytetrafluoroethylene (PTFE) liners reinforced with stainless steel braiding to deliver unprecedented performance. Research by SAE International shows hydraulic steering systems using PTFE technology exhibit 38% lower flow resistance compared to conventional alternatives. This reduction translates directly to decreased steering effort and enhanced driver control, especially in low-speed maneuvering scenarios where restricted power steering hoses may cause excessive steering effort.

Three critical performance parameters establish PTFE's superiority: First, its near-zero porosity eliminates fluid permeation that causes hose swelling in standard components. Second, the ultra-smooth PTFE interior surface reduces friction loss by up to 26%, optimizing hydraulic efficiency. Third, PTFE maintains structural integrity across extreme thermal conditions (-65°F to 450°F), preventing the hardening issues that plague rubber hoses during temperature cycling. These characteristics are particularly valuable in modern drive-by-wire systems where consistent hydraulic pressure is non-negotiable for safety.

Field testing conducted by leading automakers reveals substantial operational benefits over standard hydraulic systems. Vehicles equipped with PTFE power steering hoses demonstrated 73% longer service intervals before maintenance intervention. Thermal imaging studies showed PTFE assemblies maintained temperature differentials under 9°F during continuous lock-to-lock steering tests, outperforming conventional hoses by significant margins. This thermal stability prevents fluid degradation and maintains consistent viscosity, ensuring predictable steering response across operating conditions.

Material Properties: Why PTFE Outperforms Conventional Materials

The molecular structure of PTFE creates unique performance characteristics that solve persistent problems in hydraulic steering. PTFE's fluorocarbon backbone creates the most chemically inert surface known to engineering, resisting oxidation and corrosion from steering fluid additives that compromise rubber compounds. Its lubricity coefficient of 0.05–0.10 is nearly ten times lower than SAE-grade nitrile rubber, enabling hydraulic fluid to flow without turbulent resistance that degrades steering feedback. Crucially, PTFE doesn't suffer plasticizer migration that causes rubber hardening after 3-5 years of service.

When reinforced with Type 304 stainless steel braiding, these hoses achieve burst pressures exceeding 8,000 PSI while maintaining flexibility at a minimum bend radius of 5× the nominal diameter. Standard 3/8" hydraulic assemblies withstand only 3,500 PSI. The dual-layer helix winding technique applied in premium power steering power hose construction provides kink resistance while eliminating expansion under pressure pulses. Independent lab testing reveals PTFE assemblies expand less than 0.2% volume per 1,000 PSI compared to 3-5% for rubber alternatives, ensuring precise hydraulic pressure modulation.

Environmental resilience presents another compelling advantage. PTFE hoses resist ozone degradation, UV radiation damage, and salt corrosion that cause premature failures in coastal climates. ASTM B117 salt spray testing confirms PTFE assemblies maintained perfect pressure integrity after 1,000 hours of exposure—eight times longer than OEM rubber assemblies. This corrosion resistance prevents the flaking debris that clogs steering racks and causes restricted power steering hoses.

Leading Manufacturers and Product Specifications Comparison

| Manufacturer | Product Name | Material | Pressure Rating | Temperature Range | Lifetime Warranty |

|---|---|---|---|---|---|

| Parker Hannifin | Parflex Ultimate | Virgin PTFE/316SS | 5,800 PSI | -65°F to 400°F | Yes |

| Eaton Aeroquip | Startlite ST PTFE | Modified PTFE/304SS | 4,200 PSI | -40°F to 350°F | 10 years |

| Dynaflex | PowerThread | Carbon-filled PTFE/302SS | 3,800 PSI | -30°F to 300°F | 7 years |

| OEM Standard | N/A | EPDM Rubber | 1,800 PSI | -20°F to 220°F | 3 years |

Industry leaders like Parker Hannifin leverage precision extrusion techniques to achieve PTFE liner thickness tolerances within ±0.001", eliminating flow inconsistencies that plague lower-tier manufacturers. Their proprietary triple-braid reinforcement pattern increases fatigue resistance by 40% compared to standard braiding when subjected to vibration levels exceeding 15 G-force. Premium-grade assemblies undergo individual hydrostatic testing at 1.5× operating pressure with digital pressure decay verification.

Material composition represents another differentiation point. Leading manufacturers exclusively use chemically stabilized virgin PTFE instead of reprocessed compounds that crystallize prematurely. The stainless steel braiding in premium PTFE power steering hoses features specialized annealing treatments that prevent work hardening during installation and flexure cycles. Independent destructive testing shows top-tier assemblies maintain safety factors above 4:1 during pressure cycling at 5 Hz frequency.

Custom Solutions for Diverse Applications

Modern PTFE hydraulic hose fabrication technology enables precise tailoring for specific vehicle platforms and operational environments. Using 3D scanning integration, manufacturers develop application-specific hose assemblies that eliminate clearance issues and reduce routing complexity. For racing applications where space constraints are critical, manufacturers can create custom-configured PTFE power steering hoses with bend radii as tight as 2.5× the outer diameter without compromising flow characteristics.

Specialized compound formulations address unique performance requirements. Electrically conductive PTFE variants prevent static charge accumulation in hybrid drivetrains, while glass-reinforced liners handle abrasive steering fluids in commercial mining equipment. For arctic operations, cryogenically stable PTFE formulations with flexible fluoropolymer jacketing maintain -76°F serviceability without embrittlement. Reverse-engineering damaged assemblies via coordinate measurement machines allows manufacturers to duplicate obsolete configurations for classic car restorations.

Hydraulic steering adapters represent another customization frontier. CNC-machined aerospace-grade aluminum fittings with metric, JIC, and ORFS connection profiles interface with virtually any power steering system. Special sealing profiles like twin-ferrule mechanical grips prevent extrusion issues at pressure spikes exceeding 4,500 PSI. Field technicians report custom-engineered PTFE solutions reduce installation times by 45% compared to modifying universal hoses.

Real-World Success Stories in Commercial and Racing Applications

Over-the-road truck fleets provide compelling validation for PTFE hose reliability under extreme conditions. A Midwest logistics company documented 112 highway tractors running PTFE assemblies for over 1.3 million cumulative miles without steering hose replacements, compared to their previous 18-month replacement cycle. The estimated $4,700 per-truck savings in maintenance costs prompted fleet-wide PTFE conversion within 18 months.

Racing applications demonstrate performance advantages where steering feedback is mission-critical. An NHRA Top Fuel team recorded 8.5% faster reaction times after switching to custom PTFE power steering hoses. Vibration analysis revealed resonance frequencies reduced from 125 Hz to below 85 Hz, eliminating steering wheel oscillations at high-RPM launches. The team attributed their championship-winning season partially to the enhanced steering precision delivered by upgraded hydraulic components.

Agricultural equipment showcases durability improvements in contaminated environments. Combined harvester operators reported PTFE assemblies completing 15 seasons without replacement despite constant abrasive grain dust exposure—four times longer than their previous EPDM hoses. Even more impressively, no steering system contamination occurred despite multiple external hose abrasions because the stainless steel braiding contained leaks until service intervention.

Installation Guidelines and Long-Term Performance Metrics

Proper installation preserves PTFE's inherent advantages while avoiding premature failures. Technicians must maintain minimum bend radii (specified at four times the outer diameter) during routing to prevent liner collapse. Applying anti-wear paste on threaded connections prevents galling of stainless steel components during torque application. Experts recommend 20% slack length beyond connection points to accommodate drivetrain movement without stress transfer.

Diagnostic checks during installation prevent operational issues: First, verify routing clearance during full suspension articulation cycles. Second, perform pressure decay testing after installation to identify compromised fittings. Third, complete three full lock-to-lock steering cycles while monitoring for pressure fluctuations exceeding manufacturer specifications. Using thermal imaging cameras during initial operation identifies abnormal friction points requiring routing adjustments.

Long-term performance data proves PTFE's superiority over decades-long horizons. Accelerated aging studies by ISO 9001-certified facilities predict minimum 18-year service life with negligible performance degradation. Real-world tracking shows less than 0.5% internal diameter reduction after 12 years of continuous operation versus 8-12% in rubber counterparts. This dimensional stability prevents the flow restriction that makes traditional restricted power steering hoses cause excessive steering effort near end-of-life.

Future Outlook for PTFE Power Steering Hose Technology

Material science advancements are poised to enhance PTFE formulations addressing emerging vehicle requirements. Nano-engineered PTFE composites with graphene reinforcements promise thermal conductivity improvements exceeding 60%, allowing heat dissipation without external cooling. Hybrid constructions combining PTFE liners with thermoplastic outer jackets provide enhanced chemical resistance against bio-based steering fluids mandated in California emissions zones.

Electrification trends drive new development priorities. Steer-by-wire systems require PTFE power steering hoses with integrated pressure transducers and temperature sensors providing real-time diagnostics. Low-permeation formulations prevent fluid loss in sealed systems where maintenance access is intentionally limited. Vehicle manufacturers are standardizing these assemblies in next-generation platforms due to packaging efficiency—PTFE assemblies require 28% less routing space than rubber equivalents.

Sustainability initiatives reshape material sourcing. Leading manufacturers now implement closed-loop recycling programs converting PTFE waste into calibrated industrial powders for additive manufacturing. Life-cycle assessments confirm that the longevity of premium PTFE power steering hoses generates 67% lower environmental impact compared to conventional assemblies over typical vehicle lifetimes. This positions PTFE as a strategic solution for environmentally conscious engineering while delivering uncompromising steering precision throughout extended service intervals.

(ptfe power steering hose)

FAQS on ptfe power steering hose

Q: What is a PTFE power steering hose?

A: A PTFE power steering hose is a high-performance hose made with polytetrafluoroethylene (PTFE) to withstand extreme temperatures and pressure. It ensures smooth fluid transfer in power steering systems while resisting wear and corrosion.

Q: How does a PTFE power steering hose differ from a standard power steering hose?

A: PTFE hoses are more durable and heat-resistant compared to traditional rubber hoses. They reduce the risk of leaks and degradation over time, offering longer service life for power steering systems.

Q: Can restricted power steering hoses cause steering issues?

A: Yes, restricted power steering hoses may cause excessive steering effort or stiffness. Blockages or kinks limit fluid flow, forcing the driver to apply more force to turn the wheel.

Q: How often should PTFE power steering hoses be inspected?

A: Inspect PTFE power steering hoses during routine vehicle maintenance or every 30,000–50,000 miles. Look for cracks, leaks, or deformities to prevent sudden failures.

Q: What happens if a power steering hose fails?

A: A failed hose can lead to fluid loss, noisy steering, or complete loss of power assist. Immediate replacement is critical to avoid safety risks and costly repairs.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025