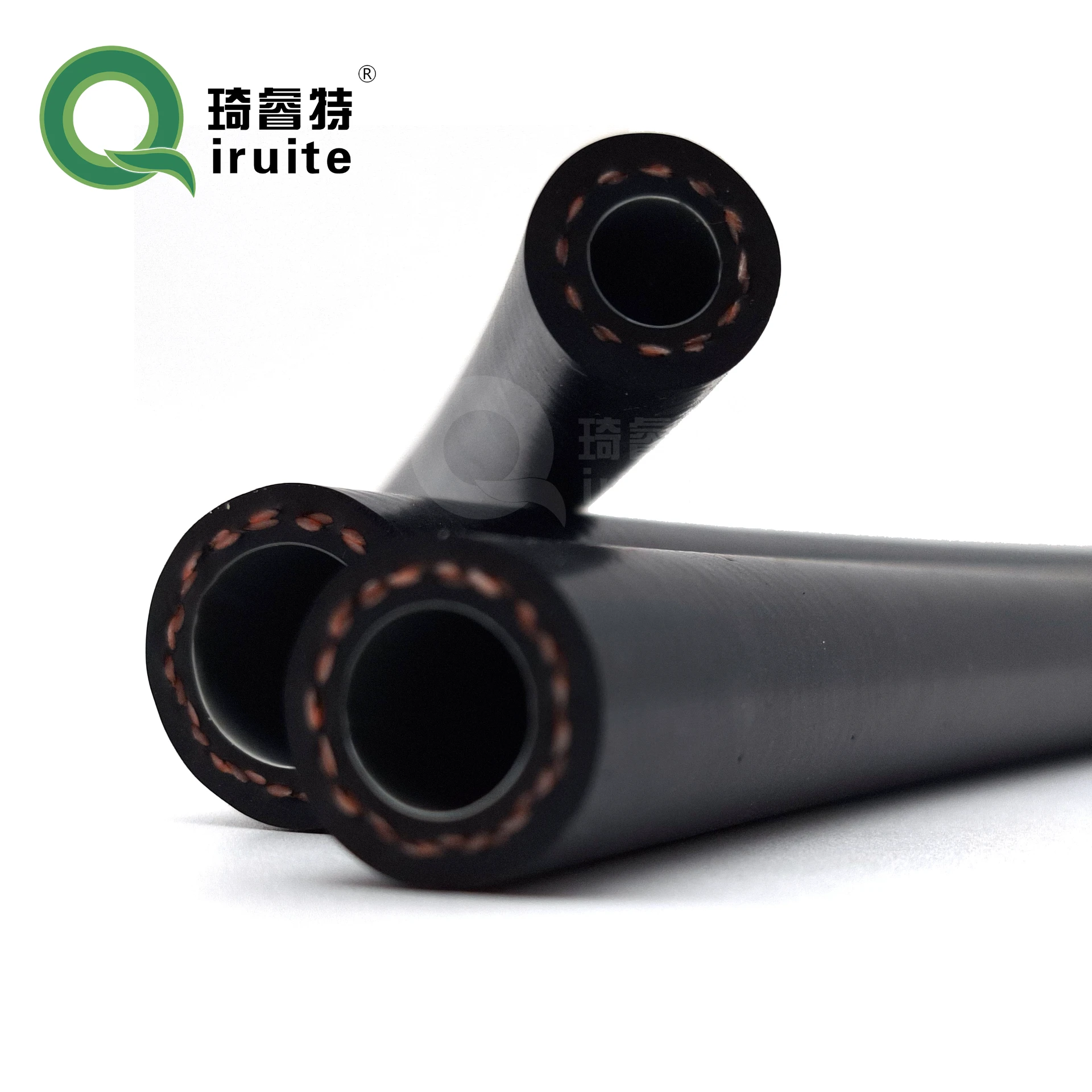

large diameter pipe couplings

Understanding Large Diameter Pipe Couplings Importance, Types, and Applications

Large diameter pipe couplings are essential components in various industrial applications, enabling the efficient connection of large pipes used for transporting fluids, gases, and other materials. These couplings ensure structural integrity, prevent leaks, and facilitate maintenance while allowing for flexibility in pipe systems. In this article, we will explore the importance of large diameter pipe couplings, their various types, and their applications in different industries.

Importance of Large Diameter Pipe Couplings

Pipes with large diameters are critical components in many sectors, including water supply, wastewater management, oil and gas transportation, chemical manufacturing, and more. Large diameter pipe couplings are crucial for ensuring the seamless connection between these pipes.

1. Leak Prevention One of the primary functions of couplings is to prevent leaks. The design and material used in couplings directly impact their ability to withstand pressure and temperature variations. High-quality couplings minimize the risk of leaks, which can lead to significant operational disruptions and environmental hazards.

2. Easy Maintenance Couplings provide the flexibility to remove and replace sections of piping without having to dismantle entire systems. This ease of maintenance is especially important in large-scale operations where downtime can be costly.

3. Support Structural Integrity Couplings not only connect pipes but also help to support the overall structure of pipe systems. They help maintain alignment and prevent stress on the joints that could lead to failures over time.

Types of Large Diameter Pipe Couplings

Several types of large diameter pipe couplings are commonly used in various applications. The choice of coupling depends on the material of the pipes, the type of fluid being transported, and the specific requirements of the application.

1. Mechanical Couplings These couplings use mechanical means, such as bolts and clamps, to connect pipes. They are popular for their ease of installation and disassembly, making them ideal for applications where frequent maintenance is necessary.

2. Welded Couplings These involve welding the ends of the pipes together using a filler material. Welded couplings provide a strong and permanent joint, making them suitable for high-pressure applications, such as in oil and gas pipelines.

large diameter pipe couplings

3. Flanged Couplings These include two flanges that are bolted together with a gasket in between to create a seal. Flanged couplings are often used where pipes need to be connected and disconnected frequently, allowing for easy access during maintenance.

4. Socket Weld Couplings These are used for joining pipes at a right angle, where the pipe is inserted into a socket and then welded in place. This type of coupling is beneficial in applications with limited space and allows for a strong and leak-proof connection.

5. Expansion Couplings Used in locations where thermal expansion is a concern, these couplings accommodate movement caused by temperature changes. They are designed to absorb stress and provide flexibility within the piping system.

Applications of Large Diameter Pipe Couplings

Large diameter pipe couplings find applications across a myriad of industries

- Water and Wastewater Management In municipal water supply systems, large diameter pipes transport large volumes of water, and couplings ensure the reliability and integrity of these systems.

- Oil and Gas The transportation of crude oil and natural gas through pipelines requires robust couplings that can withstand high pressures and harsh environmental conditions.

- Construction In construction projects, large pipes are often used for drainage systems, and appropriate couplings allow for effective connections that prevent leaks and maintain structural integrity.

- Mining Large diameter piping systems are essential for slurry transport in mining operations. Couplings must provide reliable connections that can handle abrasive materials.

Conclusion

Large diameter pipe couplings play a vital role in ensuring the efficiency, safety, and reliability of various piping systems across multiple industries. Understanding the different types of couplings and their specific applications can lead to better decision-making in the selection and maintenance of piping systems. As industries continue to evolve and expand, the importance of these couplings will only grow, making them indispensable components in modern infrastructure.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025