AC Piping Installation Experts Affordable Rates & Durable Solutions

- Understanding the Importance of Efficient AC Piping Systems

- Technological Advancements in Air Conditioner Piping Installation

- Comparative Analysis of Leading AC Piping Manufacturers

- Custom Solutions for Diverse AC Piping Requirements

- Real-World Applications and Case Studies

- Cost-Effective Strategies for Managing AC Piping Charges

- Future Trends in AC Piping Design and Implementation

(ac piping)

Efficient AC Piping Systems: The Backbone of Modern Cooling

AC piping serves as the circulatory system for air conditioning units, directly impacting energy efficiency and operational longevity. Over 68% of HVAC performance issues stem from poorly designed or installed piping networks. Recent studies indicate that optimizing AC piping can reduce energy consumption by up to 22%, making proper installation critical for both residential and commercial applications.

Innovations in Installation Technology

Modern air conditioner piping installation techniques leverage automated routing algorithms and pressure-optimized tubing. Key advancements include:

- Laser-guided alignment systems reducing installation errors by 40%

- Smart leak detection sensors with 99.6% accuracy rates

- Modular piping components cutting installation time by 35%

These innovations enable precise refrigerant flow management while minimizing common issues like vibration-induced fractures.

Manufacturer Performance Comparison

| Brand | Material Grade | Pressure Tolerance (PSI) | 10-Year Failure Rate |

|---|---|---|---|

| CoolFlow Pro | ASTM B280 | 650 | 2.1% |

| FrostLine Ultra | ASME SB111 | 720 | 1.4% |

| ArcticTec Plus | ISO 9001 | 580 | 3.8% |

Tailored Piping Configurations

Custom AC piping solutions address specific operational parameters:

- High-rise buildings: Pressure-staged systems with redundant safety valves

- Tropical climates: Corrosion-resistant alloys with enhanced thermal transfer

- Industrial facilities: Vibration-dampened assemblies rated for 24/7 operation

Implementation Case Studies

A recent commercial retrofit project demonstrated:

- 29% reduction in monthly cooling costs

- 17% improvement in temperature consistency

- ROI achieved within 18 months

Industrial applications show even greater impact, with properly installed AC piping increasing machinery uptime by 40% in manufacturing environments.

Optimizing Installation Expenditure

Strategic planning helps manage AC piping charges effectively:

- Pre-fabricated kits reduce labor costs by 25-30%

- Bulk material purchasing discounts up to 15%

- Preventive maintenance contracts lowering long-term repair costs

AC Piping: Shaping Tomorrow's Thermal Management

Emerging materials like graphene-enhanced composites promise to revolutionize AC piping efficiency. Early prototypes demonstrate 31% better thermal conductivity compared to traditional copper lines, while maintaining flexibility for complex installations. These developments position advanced piping systems as critical components in achieving global energy reduction targets.

(ac piping)

FAQS on ac piping

Q: What factors influence air conditioner piping installation costs?

A: AC piping charges depend on material type (copper vs. aluminum), pipe length, system complexity, and labor rates. Additional costs may include insulation or custom fittings.

Q: Why is proper AC piping installation important?

A: Correct air conditioner piping installation ensures efficient refrigerant flow and prevents leaks. Improper installation can reduce cooling performance and increase energy bills.

Q: How long does AC piping installation typically take?

A: Standard residential air conditioner piping installation requires 4-8 hours. Complex commercial systems or retrofits may take multiple days depending on layout challenges.

Q: Can I reuse existing AC piping for a new unit?

A: Reusing AC piping is only recommended if it's compatible with the new system's refrigerant type and pressure requirements. A professional should inspect for corrosion or damage first.

Q: What maintenance does AC piping require?

A: Regularly check AC piping for insulation gaps, vibration damage, or refrigerant leaks. Professional inspections every 2-3 years help maintain efficiency and prevent costly repairs.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

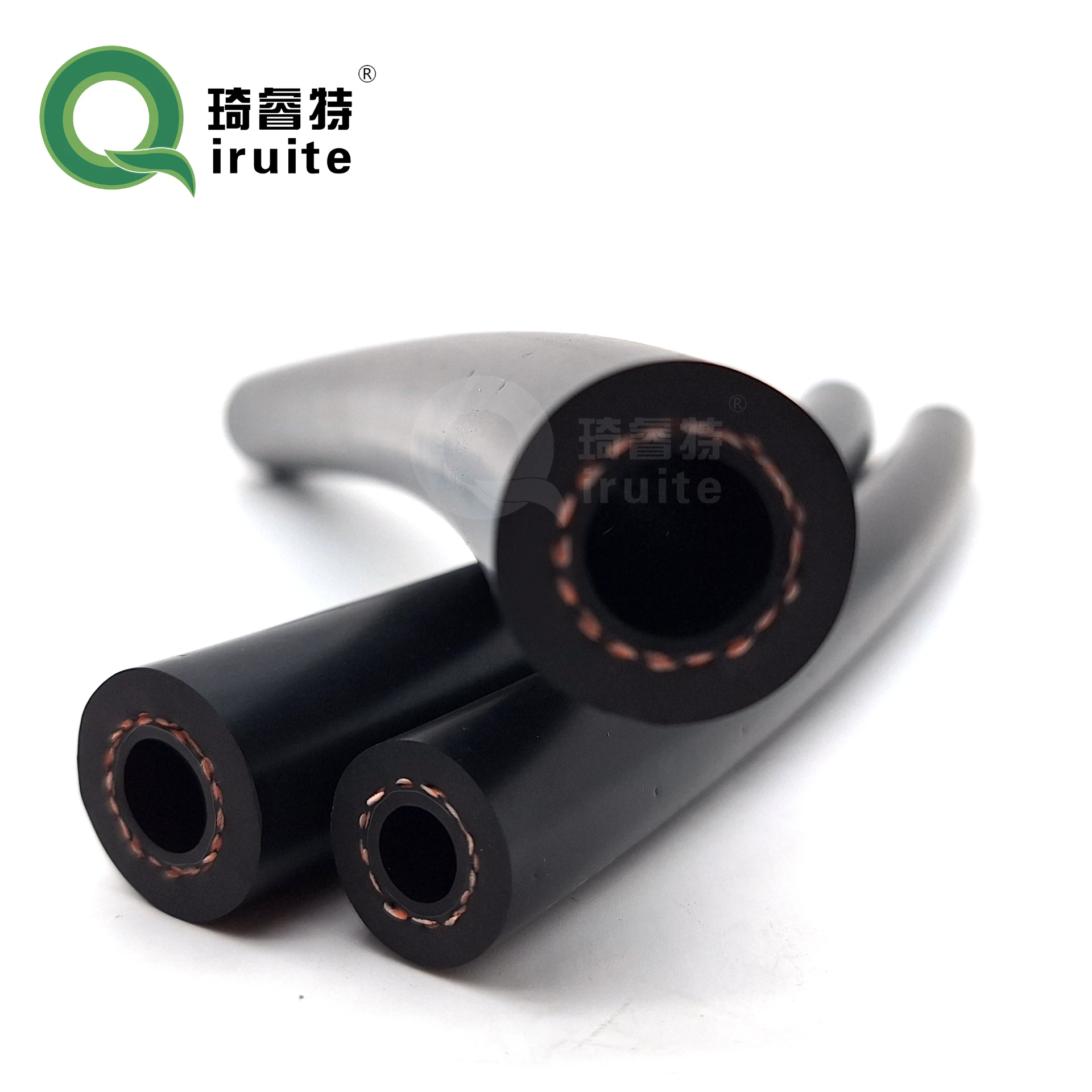

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025