Understanding Pipe Coupling Fittings for Efficient Plumbing and Construction Applications

Understanding Pipe Coupling Fittings The Backbone of Plumbing Systems

In the realm of plumbing, the efficiency and integrity of water and fluid transport systems greatly depend on the selection and application of appropriate fittings. Among the various components that facilitate these connections, pipe coupling fittings stand out as crucial elements. These fittings not only ensure fluid transport but also play a significant role in maintaining the reliability and safety of piping systems.

Definition and Purpose

Pipe coupling fittings are essentially mechanical devices designed to connect two sections of pipes together, enabling smooth fluid flow from one segment to another. These fittings serve multiple purposes, including extending pipe lengths, changing pipe sizes, and redirecting flow directions. In essence, they are the connectors that manage the intricate web of piping in residential, commercial, and industrial settings.

Types of Pipe Coupling Fittings

There are several types of pipe coupling fittings, each designed for specific applications

1. Full Coupling This type allows for a complete connection between two pipes of the same diameter. Full couplings are typically used in straight runs or to extend a line.

2. Reducing Coupling In instances where pipes of different diameters need to be joined, reducing couplings come into play. They enable the connection between a larger pipe and a smaller one, making them essential for various plumbing applications.

3. Screw Coupling Utilized primarily in situations where a quick disconnect is essential, screw couplings are simple to install and remove, making maintenance and repairs more manageable.

4. Flexible Coupling Designed to accommodate slight misalignments or movements in piping, flexible couplings are crucial in areas that experience vibrations or thermal expansions.

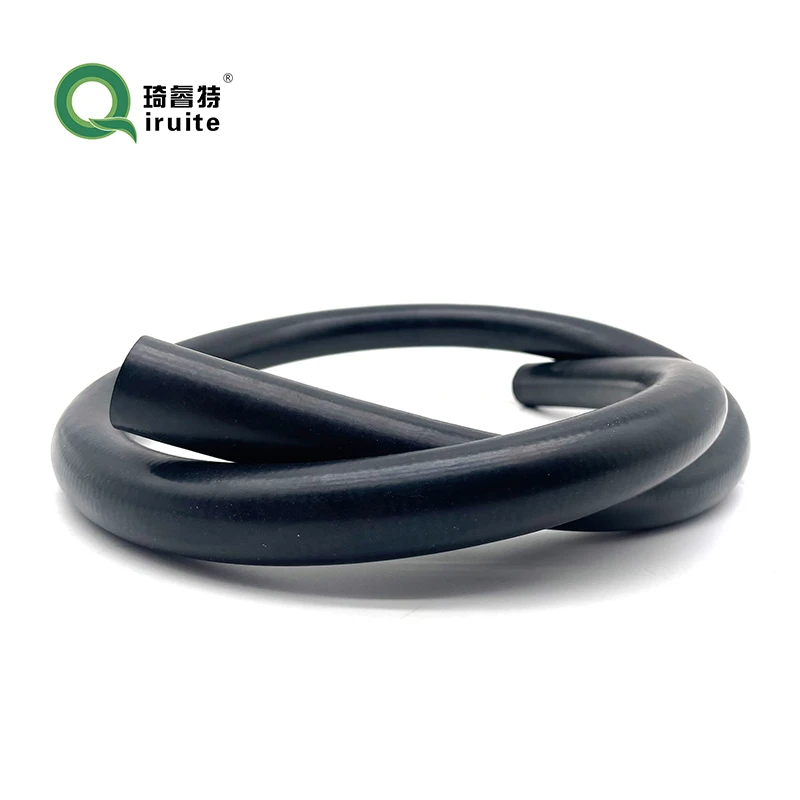

pipe coupling fitting

Material Considerations

The choice of material for pipe coupling fittings is equally vital. Common materials include

- PVC (Polyvinyl Chloride) Lightweight, corrosion-resistant, and easy to install, PVC fittings are popular in residential plumbing and irrigation systems.

- Metal (Stainless Steel, Copper) These materials provide durability and strength, making them suitable for high-pressure applications, including industrial settings.

- CPVC (Chlorinated Polyvinyl Chloride) Known for its ability to withstand higher temperatures, CPVC fittings are ideal for hot water systems.

Installation and Maintenance

Correct installation of pipe coupling fittings is essential to ensure optimal performance. It is crucial to follow manufacturer guidelines and industry standards during installation. Ensuring proper alignment, using compatible materials, and sealing connections appropriately can prevent leaks, which are common issues that often arise from improper installation.

Regular maintenance is also necessary to extend the life of pipe coupling fittings. This includes checking for signs of wear, corrosion, or leaks, and promptly replacing any damaged fittings. Neglecting these tasks can lead to significant plumbing problems, including water damage and system failures.

Conclusion

In summary, pipe coupling fittings are indispensable components of plumbing systems that facilitate the efficient transfer of fluids. Understanding the various types and materials, as well as adhering to proper installation and maintenance practices, can vastly improve the reliability and longevity of piping systems. Whether for a small home project or a large industrial operation, selecting the right fitting is critical for ensuring seamless operations and preventing costly repairs in the future. Investing time in understanding these fittings is, therefore, not just wise but necessary for any successful plumbing endeavor.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025