Plain End Pipe Connection Fittings for Efficient Piping Solutions in Various Applications

Understanding Plain End Pipe Coupling A Comprehensive Guide

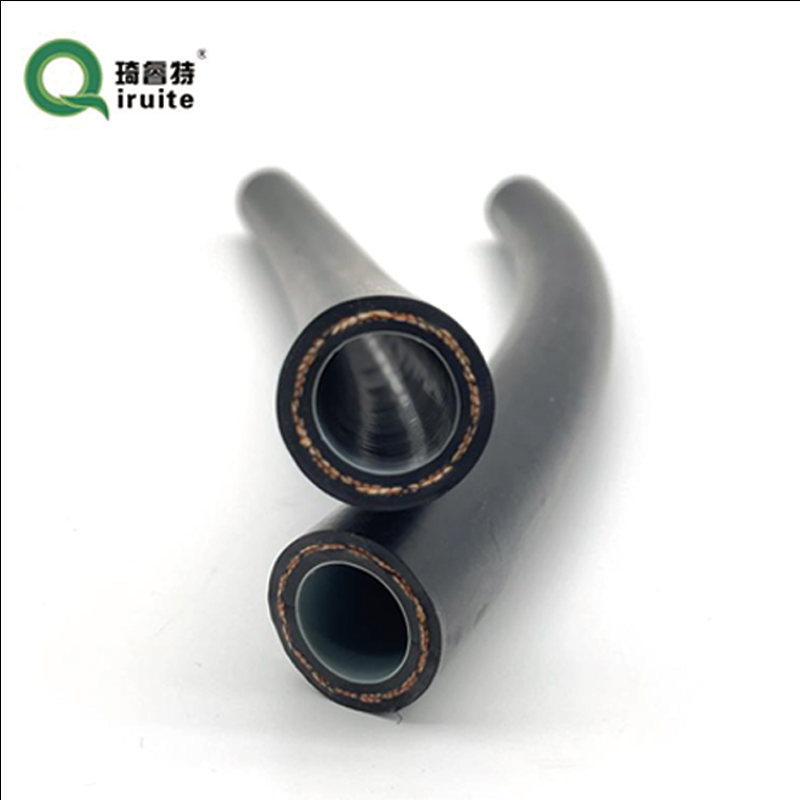

Plain end pipe coupling is a crucial component in various industries, particularly in plumbing, construction, and manufacturing. This simple yet effective fitting allows for the joining of two pipe sections, ensuring fluid or gas can flow seamlessly through a pipeline. To grasp the importance and application of plain end pipe coupling, it is essential to explore its design, types, installation procedures, and advantages.

Design and Functionality

A plain end pipe coupling typically consists of two ends with no specialized finishing or threading, allowing for easy connection to plain end pipes. Its design is straightforward but serves a significant purpose, enabling quick assembly and disassembly of pipelines. The coupling can be made from various materials, including stainless steel, carbon steel, brass, and plastic. The choice of material often depends on the application, pressure, and temperature of the fluids being transported.

Types of Couplings

There are several types of plain end pipe couplings, each designed for specific applications and conditions. The most common types include

1. Screwed Coupling Often used in low-pressure systems, this type combines plain end pipes with threads, providing a secure connection. However, it may require additional sealing agents to prevent leaks.

2. Welded Coupling This approach involves welding the coupling to the pipes, creating a permanent joint that can withstand high pressures and temperatures. Welded couplings are ideal for industrial applications where durability is critical.

3. Socket Welding Coupling Here, the plain end of the pipe fits into a socket on the coupling, and welding surrounds it. This type is commonly used in high-pressure systems and offers a strong and leak-proof seal.

4. Flanged Coupling Though more complex, this coupling features flanges at both ends, allowing for easy connection and disconnection. Flanged couplings are advantageous in systems that require regular maintenance.

Installation Procedures

Installing a plain end pipe coupling requires careful consideration to ensure a secure and leak-free connection

. The following steps outline a typical installation process1. Preparation Ensure all pipes are cut squarely and the ends are cleaned to remove any debris or burrs. This preparation is crucial for a tight fit.

plain end pipe coupling

2. Aligning Pipes Position the pipes so that they align perfectly. Misalignment can lead to stress and potential failures in the system.

3. Securing the Coupling Depending on the type of coupling used, secure it to the pipe ends using the appropriate method (screwing, welding, or fastening).

4. Testing After installation, conduct a pressure test to check for leaks. This step is essential to ensure that the joint can handle operational pressures.

5. Insulation In some applications, insulating the joint may be necessary to prevent heat loss or gain, particularly in HVAC systems.

Advantages of Plain End Pipe Coupling

Plain end pipe couplings offer several benefits that make them a preferred choice in the industry

- Simplicity Their straightforward design allows for easy installation and maintenance, reducing labor costs and time.

- Versatility Available in various materials and sizes, these couplings can be used in a wide range of applications, from residential plumbing to large industrial systems.

- Cost-effectiveness Generally, plain end couplings are less expensive than their threaded or flanged counterparts, making them budget-friendly for large-scale projects.

- Reliability With proper installation, plain end couplings can provide a reliable connection capable of handling different pressures and conditions.

Conclusion

In summary, plain end pipe coupling is a vital element in connecting piping systems across various sectors. Its design, types, installation methods, and inherent advantages make it an essential component for efficient fluid or gas transportation. Understanding the nuances of plain end pipe coupling can significantly contribute to effective pipeline management and maintenance, ensuring safe and reliable operation in numerous applications. Whether in residential plumbing or major industrial facilities, the plain end pipe coupling remains an indispensable tool in the world of piping systems.

-

Understanding Power Steering Tube ReplacementNewsApr.16,2025

-

SAE J1401 Brake Hoses: A Critical Component for Vehicle SafetyNewsApr.16,2025

-

Pipe Couplings: Essential Components for Effective Plumbing and Fluid SystemsNewsApr.16,2025

-

Hose Guard Solutions for Every NeedNewsApr.16,2025

-

Effective Spiral Protection SolutionsNewsApr.16,2025

-

Effective Sewer Cleaning SolutionsNewsApr.16,2025