jan . 25, 2025 22:38

Back to list

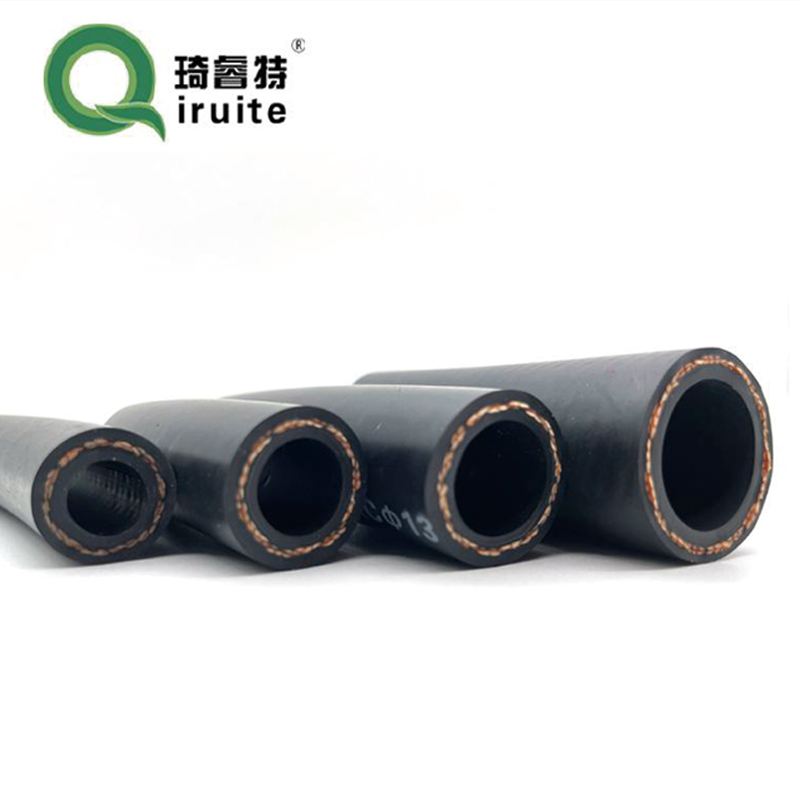

pressure washer jet hose

The intricacies of rotating pipe couplings reveal a remarkable intersection of engineering ingenuity and practical utility, offering solutions essential for numerous industrial applications. Often serving as critical components in fluid dynamics systems, rotating pipe couplings facilitate the seamless transfer of liquids or gases between rotating and stationary sections of machinery, ensuring efficiency and minimizing potential leakages.

Building a seamless experience around rotating pipe couplings is also contingent upon rigorous testing and quality assurance practices. Industry leaders maintain stringent protocols to ensure that each coupling not only meets but exceeds established standards such as those set forth by bodies like the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO). This validation process is essential in establishing the credibility and trustworthiness of the products, underscoring their safety and reliability in even the most demanding environments. User experience is further enhanced through expert customer support and detailed documentation, empowering end-users with the knowledge needed to install, operate, and maintain their couplings effectively. Manufacturers often provide comprehensive guides and tutorials that elucidate complex technical specifications and practical maintenance instructions, ensuring that operators can maximize the efficacy of the couplings throughout their lifecycle. As we pivot towards a future increasingly defined by automation and digital integration, the role of rotating pipe couplings is poised for evolution. On the horizon lies the potential for integrating smart technology into these systems, allowing for real-time monitoring and predictive maintenance using sensors to detect wear or potential failures ahead of time. This forward-thinking approach not only ensures operational continuity but also enhances safety standards, giving facilities a competitive edge in resource management and operational efficiency. In conclusion, the world of rotating pipe couplings is a testament to engineering excellence and the pivotal role these components play in countless industrial processes. Through continual innovation and a commitment to quality, they provide reliability and efficiency, essential characteristics that bolster their standing as indispensable tools in the contemporary industrial landscape. For any entity striving for excellence in their systems, an informed choice of rotating pipe couplings defines not just the immediate success of operational protocols but also the enduring performance and safety of their industrial processes.

Building a seamless experience around rotating pipe couplings is also contingent upon rigorous testing and quality assurance practices. Industry leaders maintain stringent protocols to ensure that each coupling not only meets but exceeds established standards such as those set forth by bodies like the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO). This validation process is essential in establishing the credibility and trustworthiness of the products, underscoring their safety and reliability in even the most demanding environments. User experience is further enhanced through expert customer support and detailed documentation, empowering end-users with the knowledge needed to install, operate, and maintain their couplings effectively. Manufacturers often provide comprehensive guides and tutorials that elucidate complex technical specifications and practical maintenance instructions, ensuring that operators can maximize the efficacy of the couplings throughout their lifecycle. As we pivot towards a future increasingly defined by automation and digital integration, the role of rotating pipe couplings is poised for evolution. On the horizon lies the potential for integrating smart technology into these systems, allowing for real-time monitoring and predictive maintenance using sensors to detect wear or potential failures ahead of time. This forward-thinking approach not only ensures operational continuity but also enhances safety standards, giving facilities a competitive edge in resource management and operational efficiency. In conclusion, the world of rotating pipe couplings is a testament to engineering excellence and the pivotal role these components play in countless industrial processes. Through continual innovation and a commitment to quality, they provide reliability and efficiency, essential characteristics that bolster their standing as indispensable tools in the contemporary industrial landscape. For any entity striving for excellence in their systems, an informed choice of rotating pipe couplings defines not just the immediate success of operational protocols but also the enduring performance and safety of their industrial processes.

Next:

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025