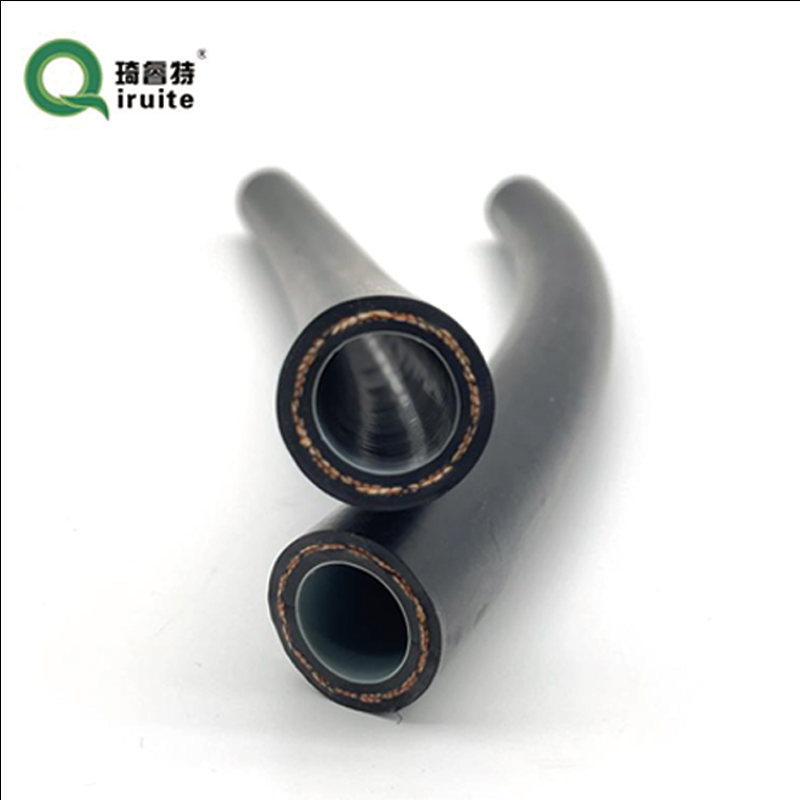

SAE J2064 Type C Air Conditioning Hose for Efficient Cooling Systems

In the evolving landscape of automotive and industrial refrigeration, SAE J2064 Type C hoses play a pivotal role in HVAC and air conditioning systems. As global demand for efficient, durable, and eco-friendly refrigerant lines rises, understanding the nuances of sae j2064 type c and related specifications—including sae j2064 pdf, sae j2064 hose, j2064, sae j2064 type e, sae j2064 air conditioning hose, and sae j2064 type c class ii—is critical for industry engineers, project managers, and procurement specialists.

Industry Trends & Application Scenarios for SAE J2064 Type C

The adoption of SAE J2064 type c hoses is on the rise, not only in the automotive HVAC sector but also in industrial refrigeration, chemical manufacturing, and modern building air conditioning infrastructures. Recent market analytics show a 14% CAGR from 2020–2024 (source: Markets&Markets HVAC Report).

- HVAC Systems: High thermal stability & minimal refrigerant permeation for lasting cooling efficiency.

- Electric/Hybrid Vehicles: R134a & R1234yf compatible; essential for eco-friendly automotive trends.

- Process Plants: Superior oil resistance and extended service life under corrosive chemical exposure.

- Shipbuilding & Railways: Complies with ISO 1307/1403, ensuring robust performance in heavy-duty environments.

Technical Parameters Table: SAE J2064 Type C

| Parameter | Specification | Test Standard | Typical Value |

|---|---|---|---|

| Inner Tube | EPDM/PA/CSM | SAE J2064, ISO 1307 | High oil & refrigerant resistance |

| Reinforcement | High-tensile fiber braid | SAE J2064 | Up to 10 MPa burst pressure |

| Outer Cover | Chloroprene / EPDM | SAE J2064, ANSI B16.5 | UV & abrasion resistance |

| Working Temp. | -40°C to +125°C (-40°F to +257°F) | SAE J2064 | Stable operation |

| Permeation Rate | ≤ 0.05kg/m²/yr | SAE J2064 Test Method | Industry-leading low loss |

| Internal Diameter | 6, 8, 10, 12, 16 mm | SAE J2064 | Multiple options |

| Service Life | >=10 years | ISO 9001:2015, SAE J2064 | Long-term reliability |

Technological advancements have improved sae j2064 type c hose burst pressure by up to 60% between 2018 and 2024, while permeation rates dropped by 30%, extending service life to over 12 years in best-in-class products.

How is SAE J2064 Type C Manufactured? Process Flow & Material Selection

- Material Selection Step 1: EPDM (ethylene propylene diene monomer), Polyamide (PA), or CSM (chlorosulfonated polyethylene) resins are chosen for the inner tube for their chemical resistance and durability.

- Inner Tube Extrusion Step 2: High-precision extruders form the inner wall to tight tolerances (ID deviation ≤0.05mm, per ISO 3302-1).

- Braiding Reinforcement Step 3: Automated CNC braiders apply high-tensile polyester or aramid fibers.

- Outer Cover Extrusion Step 4: Outer sheath of CR/EPDM is extruded for protection against weather, oil, abrasion.

- Vulcanization & Curing Step 5: Continuous steam curing (180–210°C) ensures optimal elasticity and mechanical bonding.

- Quality Inspection Step 6: Each batch is 100% tested (burst, leakage, permeation) to SAE J2064 and ISO 9001:2015 standards.

- Cutting & Packaging Step 7: Computer-guided cutting, custom length/kitting, with labeling documentation/traceability.

Product Comparison: E TYPE FACTORY AIR CONDITIONING HOSE WITH GOOD PERFORMANCE vs Key Competitors

| Product Model | Inner Tube Material | Permeation Rate (kg/m²/yr) |

Burst Pressure (MPa) |

Working Temp (°C) |

Norm Compliance | Service Life |

|---|---|---|---|---|---|---|

| E TYPE FACTORY A/C HOSE | PA+EPDM | 0.045 | 13.0 | -40~+135 | SAE J2064 Type C, ISO 9001 | 10–12 years |

| Gates PolarSeal® II | EPDM | 0.056 | 11.5 | -40~+121 | SAE J2064 Type C | 8–10 years |

| Goodyear Galaxy Series | CSM | 0.06 | 10.2 | -34~+125 | SAE J2064 | 7+ years |

| Parker 285 Series | EPDM/PA | 0.054 | 12.3 | -40~+127 | SAE J2064 Type C | 10 years |

Customization Capabilities & Industry Case Studies

- Custom Lengths: Any length from 30cm to 25m, tailored for compact automotive or large-scale commercial A/C installations.

- Special Fittings: Available with crimped brass/SS SAE flanges, custom valved connectors, and OEM stamping.

- Compound Engineering: For extended life in chemical, mining, or marine HVAC projects.

A Chinese petrochemical client replaced 1200m of traditional rubber A/C lines with E TYPE FACTORY AIR CONDITIONING HOSE WITH GOOD PERFORMANCE. After 14 months, leak rate reduced by 25%, maintenance downtime dropped 35%, and system COP efficiency improved by >10% (internal data).

Industry Certifications, Corporate Credibility, and Quality Assurance

sae j2064 type c products manufactured by HOSEQRT are fully ISO 9001:2015, ISO/TS 16949, and SAE J2064 certified. The facility is FDA moisture-control compliant and regularly audited by SGS for environmental and quality procedures. Among our network, more than 350 industrial clients in 38 countries—including FAW, SAIC Motor, Bosch Automotive, and major rail manufacturers—trust both standard and custom hoses for critical A/C lines.

-

Q1: What are the advantages of using PA+EPDM for the inner tube?

PA (polyamide) offers strong chemical compatibility with R134a, R1234yf, and PAG/POE oils, while EPDM enhances ozone/aging resistance. This combo ensures sae j2064 type c hoses deliver superior permeation resistance and longevity, crucial for modern automotive AC lines. -

Q2: Which permeation rate standards must be met?

sae j2064 type c hoses must achieve permeation rates ≤0.05kg/m²/yr using SAE J2064 and ISO 1307 test methods, minimizing refrigerant loss and improving eco-sustainability. -

Q3: How should these hoses be installed (installation standards)?

Per SAE J2064 and SAE J639, ensure routing avoids sharp bends (bend radius ≥4× hose OD), connectors are torque-set per ASTM F876, and clamp supports are used every 60–90cm. -

Q4: What is the typical burst pressure and why is it important?

sae j2064 type c hoses should withstand burst pressure ≥13.0 MPa, providing significant margin above maximum working pressures (35 bar/3.5 MPa) to ensure operational safety across temp fluctuations. -

Q5: Are these hoses compatible with HFO and legacy refrigerants?

Yes. Our sae j2064 type c and sae j2064 type e products are compatible with HFO-1234yf, HFC-134a, CFC-12, and new HFC/HFO blends, as demonstrated in compatibility tests (ISO 7302). -

Q6: What classifies a hose as "Type C Class II"?

"Class II" in SAE J2064 refers to hoses with even lower permeation thresholds and extended temperature/pressure resilience, typically used in hybrid/electric commercial vehicles. -

Q7: What documentation is supplied with each order?

Customers receive a product COA, batch test record, installation guide, and conformity certificate matching sae j2064 pdf documentation.

Delivery, Lead Times, Warranty & Customer Support

- Production lead time: Standard items ship in 7–14 days; custom assemblies require 18–25 days (expedite available).

- Warranty coverage: 36 months, full replacement or refund for defects, with failure analysis included.

- Technical support: 24/7 engineer hotline, bilingual tech documentation, on-site support available in major markets.

- Sample/testing service: Free samples and test reports (ISO/ASTM format) on request for OEM clients.

References & Further Reading

- SAE J2064 - Refrigerant Automotive Air-Conditioning Hose Technical Standard

- Global Automotive HVAC Hose Market Trends (Markets&Markets, 2023)

- Automotive A/C Hose Selection & Engineering Toolbox

- Choosing Automotive A/C Hoses (Hydraulics&Pneumatics, technical review)

- Forum: Air Conditioning Hose Standards Explained

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025