Led . 30, 2025 02:17

Back to list

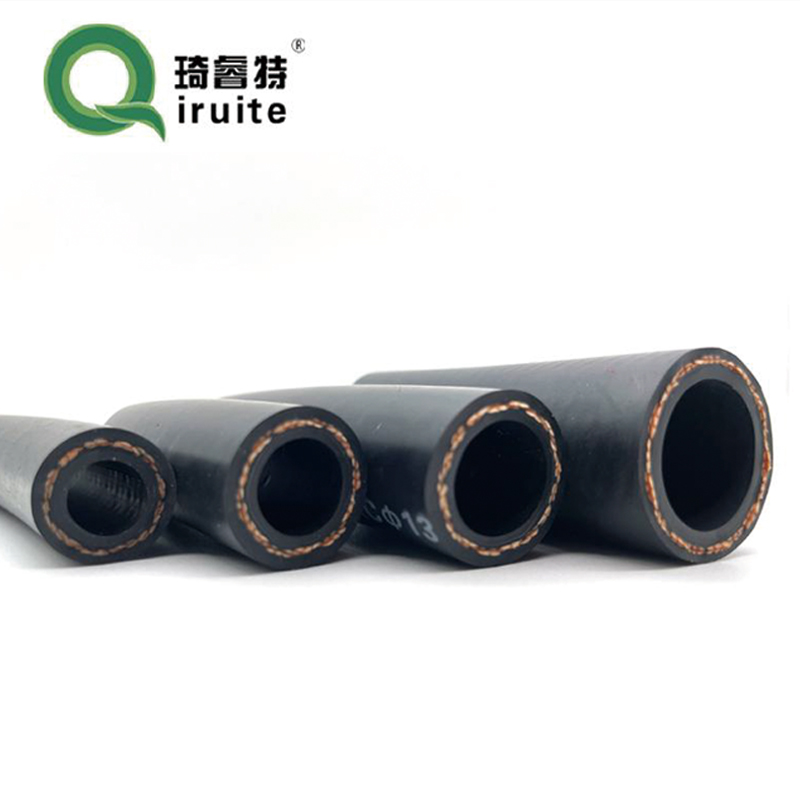

1 2 threaded pipe coupling

The world of plumbing and pipework relies heavily on the components that connect various systems to ensure efficient operation. Among these essential components, threaded pipe couplings stand out as indispensable tools for connecting pipes in both residential and industrial settings. A particularly versatile variant is the 1 2 threaded pipe coupling, which offers unique benefits and uses across multiple applications.

Furthermore, authoritativeness in the installation and inspection process is underscored by adherence to industry standards. Standards set forth by organizations such as the American Society for Testing and Materials (ASTM) and the American National Standards Institute (ANSI) govern the specifications for these couplings, ensuring quality and performance across applications. Professionals equipped with deep knowledge of these standards are better prepared to recommend and implement coupling solutions that meet rigorous operational demands. When considering trustworthiness, it’s essential to tap into product reviews and testimonials. Users often report high satisfaction with couplings that come from manufacturers boasting strong reputations and stringent quality control processes. A coupling manufactured under ISO-certified conditions, for instance, reassures users of its quality, as these certifications reflect adherence to globally recognized standards of manufacturing excellence. Lastly, while performance and technical specifications are critical, real-world experience is invaluable. This encompasses insights gained from installations, user feedback, and lessons learned from field applications. It's common for seasoned professionals to share experiences where selecting the correct coupling type and material led to cost efficiencies and prevented potential hazards, underscoring the coupling’s instrumental role in operational safety and efficiency. In conclusion, the 1 2 threaded pipe coupling is much more than a simple joiner; it is a critical component whose correct selection and application can transform the efficiency, safety, and cost-effectiveness of any piping system. With robust industry knowledge, a commitment to quality, and a focus on reliable sourcing, professionals can ensure that their systems operate with the utmost integrity and effectiveness.

Furthermore, authoritativeness in the installation and inspection process is underscored by adherence to industry standards. Standards set forth by organizations such as the American Society for Testing and Materials (ASTM) and the American National Standards Institute (ANSI) govern the specifications for these couplings, ensuring quality and performance across applications. Professionals equipped with deep knowledge of these standards are better prepared to recommend and implement coupling solutions that meet rigorous operational demands. When considering trustworthiness, it’s essential to tap into product reviews and testimonials. Users often report high satisfaction with couplings that come from manufacturers boasting strong reputations and stringent quality control processes. A coupling manufactured under ISO-certified conditions, for instance, reassures users of its quality, as these certifications reflect adherence to globally recognized standards of manufacturing excellence. Lastly, while performance and technical specifications are critical, real-world experience is invaluable. This encompasses insights gained from installations, user feedback, and lessons learned from field applications. It's common for seasoned professionals to share experiences where selecting the correct coupling type and material led to cost efficiencies and prevented potential hazards, underscoring the coupling’s instrumental role in operational safety and efficiency. In conclusion, the 1 2 threaded pipe coupling is much more than a simple joiner; it is a critical component whose correct selection and application can transform the efficiency, safety, and cost-effectiveness of any piping system. With robust industry knowledge, a commitment to quality, and a focus on reliable sourcing, professionals can ensure that their systems operate with the utmost integrity and effectiveness.

Next:

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025