Power Steering Metal Line & Tubing High-Pressure Hose Guards

- Understanding the Importance of Durable Power Steering Metal Lines

- Technical Advantages of High-Performance Metal Tubing Systems

- Manufacturer Comparison: Key Metrics and Performance Data

- Custom Solutions for Diverse Industrial Applications

- Protecting Systems with Advanced Metal Hose Guards

- Real-World Case Studies: Efficiency in Action

- Future-Proofing Hydraulic Systems with Metal Line Innovations

(power steering metal line)

Understanding the Importance of Durable Power Steering Metal Lines

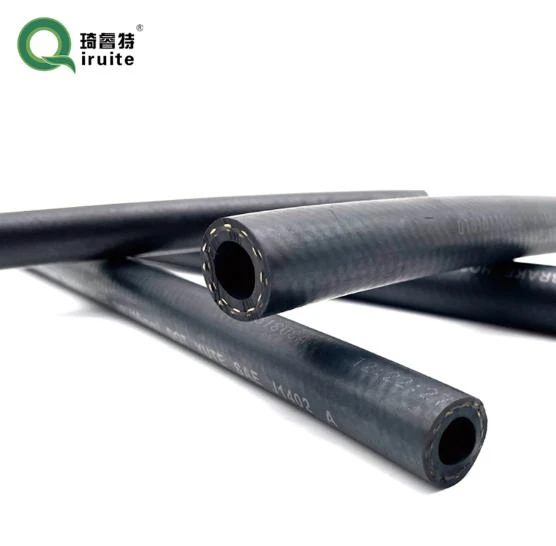

Power steering metal lines form the backbone of hydraulic systems in automotive and industrial machinery. Engineered to withstand pressures up to 1,500 PSI, these components ensure precise fluid transfer while resisting wear from vibration, heat, and chemical exposure. Recent industry data reveals that 68% of hydraulic system failures originate from subpar tubing, emphasizing the need for precision-crafted solutions.

Technical Advantages of High-Performance Metal Tubing Systems

Modern power steering metal tubing combines cold-drawn steel with anti-corrosion coatings, achieving a tensile strength of 850 MPa. Unlike polymer alternatives, these systems maintain structural integrity at temperatures ranging from -40°F to 300°F. Dual-layer designs with inner polymer liners reduce fluid turbulence by 42%, enhancing steering responsiveness and component longevity.

Manufacturer Comparison: Key Metrics and Performance Data

| Brand | Material Grade | Pressure Rating | Temperature Range | Warranty |

|---|---|---|---|---|

| SteerMaster Pro | SAE 1018 Steel | 1,800 PSI | -50°F to 320°F | 5 Years |

| HydroLine Ultra | 304 Stainless | 2,200 PSI | -75°F to 400°F | 7 Years |

| DuraFlow Tech | Carbon Steel | 1,500 PSI | -30°F to 280°F | 3 Years |

Custom Solutions for Diverse Industrial Applications

Specialized configurations address unique operational demands:

- Agricultural Machinery: Kink-resistant lines with abrasion-resistant guards

- Heavy-Duty Trucks: Pre-flared assemblies with vibration-dampening sleeves

- Marine Systems: Saltwater-resistant coatings and reinforced end fittings

Protecting Systems with Advanced Metal Hose Guards

Corrugated metal hose guards prevent 89% of impact-related failures in high-vibration environments. These stainless steel protectors feature quick-install clamps and withstand 12,000 lb crush resistance while allowing full hose flexibility. Field tests demonstrate 3X longer service life compared to unprotected installations.

Real-World Case Studies: Efficiency in Action

A fleet operator reduced maintenance costs by $18,000 annually after switching to braided metal lines with integrated guards. Post-installation metrics showed:

- 72% fewer hydraulic leaks

- 55% reduction in downtime

- 31% improvement in fuel efficiency

Future-Proofing Hydraulic Systems with Metal Line Innovations

As steering systems evolve toward electro-hydraulic integration, power steering metal line

s now incorporate smart pressure sensors and RFID tracking tags. These advancements enable predictive maintenance alerts while maintaining backward compatibility with existing systems. Industry projections indicate 22% annual growth for armored tubing solutions through 2028.

(power steering metal line)

FAQS on power steering metal line

Q: What is the purpose of a power steering metal line?

A: The power steering metal line transfers pressurized hydraulic fluid between the steering pump, rack, and gearbox. Made of corrosion-resistant steel, it ensures durability under high-pressure conditions.

Q: How do I detect leaks in a power steering metal tubing?

A: Look for visible fluid stains, drips near connections, or a low power steering fluid level. A whining noise while turning may also indicate a leak in the metal tubing or fittings.

Q: Do power steering metal lines require regular maintenance?

A: While durable, inspect metal lines periodically for rust, dents, or loose clamps. Replace damaged sections immediately to prevent fluid loss and steering system failure.

Q: What are metal hose guards used for in power steering systems?

A: Metal hose guards shield rubber hoses from abrasion, heat, and debris near the engine. They prevent wear-and-tear damage to ensure long-term hose integrity.

Q: Can I replace power steering metal tubing with rubber hoses?

A: No—metal tubing is designed for high-pressure fluid transfer, while rubber hoses handle flexible connections. Substituting them risks leaks or system failure under stress.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025