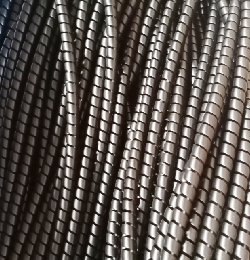

hydraulic pipe protector

The Importance of Hydraulic Pipe Protectors

In various industrial applications, hydraulic systems play a crucial role in ensuring machinery operates smoothly and efficiently. However, the delicate nature of hydraulic pipes means that they are susceptible to damage from a variety of factors, including external impacts, abrasion, and environmental conditions. This is where hydraulic pipe protectors come into play, offering essential protection to maintain the integrity and functionality of hydraulic systems.

Hydraulic pipe protectors are specially designed covers or shields that guard hydraulic lines from potential damages. These protectors are made from robust materials, often resistant to cuts, abrasions, and chemicals, ensuring that they can withstand harsh working environments. The primary function of these protectors is to prevent damaging conditions that could lead to leaks or total system failure, thereby ensuring the longevity of hydraulic systems.

One of the most significant advantages of hydraulic pipe protectors is their ability to prevent wear and tear caused by environmental factors. In industrial settings, hydraulic pipes may be exposed to weather elements such as rain, snow, or extreme temperatures that could compromise their integrity. Additionally, exposure to chemicals or corrosive substances can lead to deterioration over time. By using hydraulic pipe protectors, organizations can shield their systems from these harsh conditions, maintaining operational reliability and reducing the likelihood of unexpected downtimes.

hydraulic pipe protector

Another critical aspect is the prevention of physical damage. Hydraulic pipes often run through areas where heavy machinery operates or other objects may collide with them. This increases the risk of impacts that could cause significant harm to the piping. Hydraulic pipe protectors act as a buffer, absorbing shocks and minimizing potential damage. As a result, companies can avert costly repairs and ensure that their equipment continues to function efficiently without interruptions.

Furthermore, hydraulic pipe protectors contribute to safety in the workplace. Leaking hydraulic fluids can pose serious hazards, including slippery surfaces that increase the risk of accidents. By ensuring the pipes remain intact, protectors help maintain a safer work environment. Additionally, they can help in compliance with industry regulations, as maintaining the integrity of hydraulic systems is often a requirement in many sectors.

Another consideration is the ease of installation and maintenance that hydraulic pipe protectors offer. Many products are designed to be user-friendly, allowing for quick installations without the need for specialized tools. Furthermore, they can be easily inspected and replaced when necessary, making the upkeep of hydraulic systems more manageable.

In conclusion, hydraulic pipe protectors play an indispensable role in safeguarding hydraulic systems in various industrial applications. By offering protection against environmental factors, physical damage, and safety hazards, they not only extend the lifespan of hydraulic pipes but also enhance operational efficiency. Investing in quality hydraulic pipe protectors is a decision that pays off in the long run, as it promotes a safer, more efficient working environment while minimizing repair costs and downtime. For any industry relying on hydraulic systems, prioritizing the use of pipe protectors should be a fundamental aspect of their operational strategy.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025