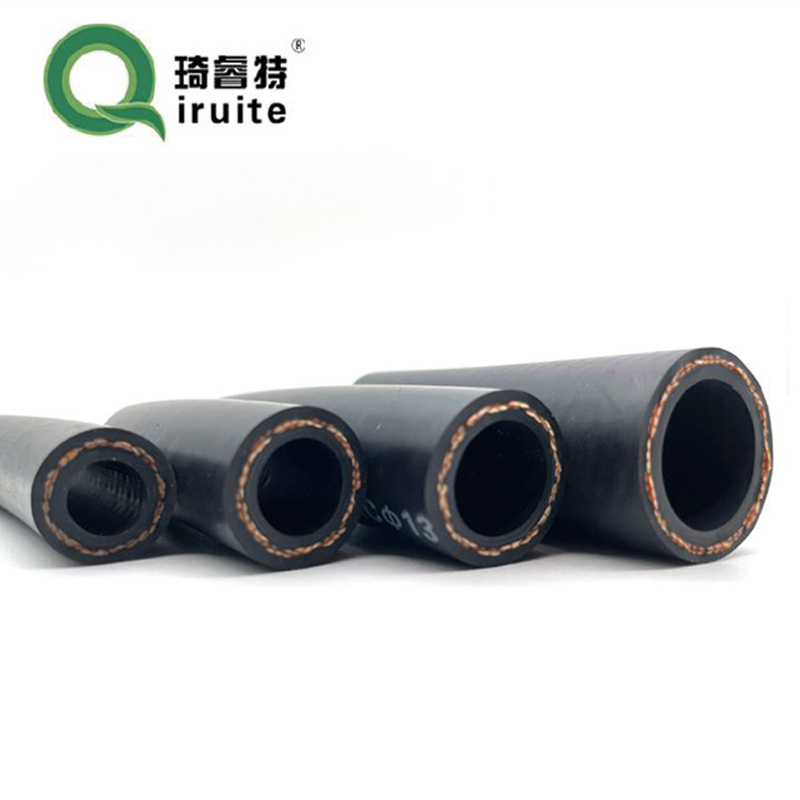

hydraulic hose guard plastic

The Importance of Hydraulic Hose Guards Protecting Your Equipment

In various industries, hydraulic hoses play a crucial role in the operation of machinery and equipment. From agricultural vehicles to construction machinery, these hoses are essential for transporting hydraulic fluid, which powers functions such as lifting, pushing, and pulling. However, the wear and tear that hydraulic hoses endure can sometimes lead to failures if proper precautions are not taken. This is where hydraulic hose guards, particularly plastic ones, come into play.

What Are Hydraulic Hose Guards?

Hydraulic hose guards are protective coverings designed to shield hydraulic hoses from damage caused by abrasion, punctures, and environmental factors. Available in various materials, plastic guards have gained popularity due to their lightweight nature, flexibility, and resilience. They not only extend the lifespan of hydraulic hoses but also contribute to the overall efficiency and safety of machinery.

Benefits of Using Plastic Hose Guards

1. Durability and Resilience Plastic hose guards are engineered to withstand harsh conditions, including extreme temperatures, UV exposure, and chemical spills. This resilience ensures that the hoses remain protected in various environments, thereby reducing the likelihood of leaks or ruptures.

2. Lightweight and Flexible Compared to other materials like metal or rubber, plastic is lightweight, making it easier to handle and install. Its flexibility allows it to conform to the shape of the hoses, providing a snug fit that enhances protection without adding unnecessary bulk.

3. Cost-Effective Solution Implementing hose guards can significantly reduce maintenance costs associated with hose repairs and replacements. A smaller investment in protective measures leads to fewer downtimes and prolonged service life for hydraulic components.

hydraulic hose guard plastic

4. Safety Enhancement Hydraulic hose failures can pose serious safety risks, particularly in high-pressure systems. By using hose guards, businesses can mitigate these risks, creating a safer working environment. In addition, hose guards help to prevent hoses from tangling or becoming entangled in moving parts, further reducing accidents.

5. Easy Installation and Maintenance Most plastic hose guards are designed for easy installation, requiring minimal tools and time. Regular maintenance also becomes more manageable, as the guards can be quickly removed for inspection or servicing of the hoses underneath.

Choosing the Right Hose Guard

When selecting a hydraulic hose guard, several factors should be considered

- Size and Compatibility The guard must fit snugly over the hose while allowing for any necessary movement without slippage. - Operating Environment Consider the specific environmental factors the hose will face, such as exposure to chemicals or extreme temperatures. - Weight Considerations Ensure the added weight of the guard will not negatively impact the equipment’s performance.

Conclusion

In conclusion, hydraulic hose guards, particularly those made from plastic, are essential for protecting hydraulic hoses in various industries. Their durability, lightweight nature, cost-effectiveness, and safety enhancements make them a smart investment for companies that rely on hydraulic systems. By taking proactive steps to protect hydraulic components, businesses can ensure equipment longevity, efficiency, and most importantly, the safety of their operations. Investing in hose guards is an investment in the future of machinery performance, operational excellence, and workforce safety.

-

Reliable Brake Line Solutions for Your VehicleNewsJun.05,2025

-

Quick Fix for Leaky Air Conditioning HosesNewsJun.05,2025

-

Powerful Sewer Jetting Solutions for Tough ClogsNewsJun.05,2025

-

Power Steering Hose Problems SolvedNewsJun.05,2025

-

Hose Protectors That Actually WorkNewsJun.05,2025

-

Essential Hose Connectors for Every HomeNewsJun.05,2025