Versatile Pipe Connector for Enhanced Flexibility and Easy Installation

Understanding Flexible Pipe Connectors Benefits and Applications

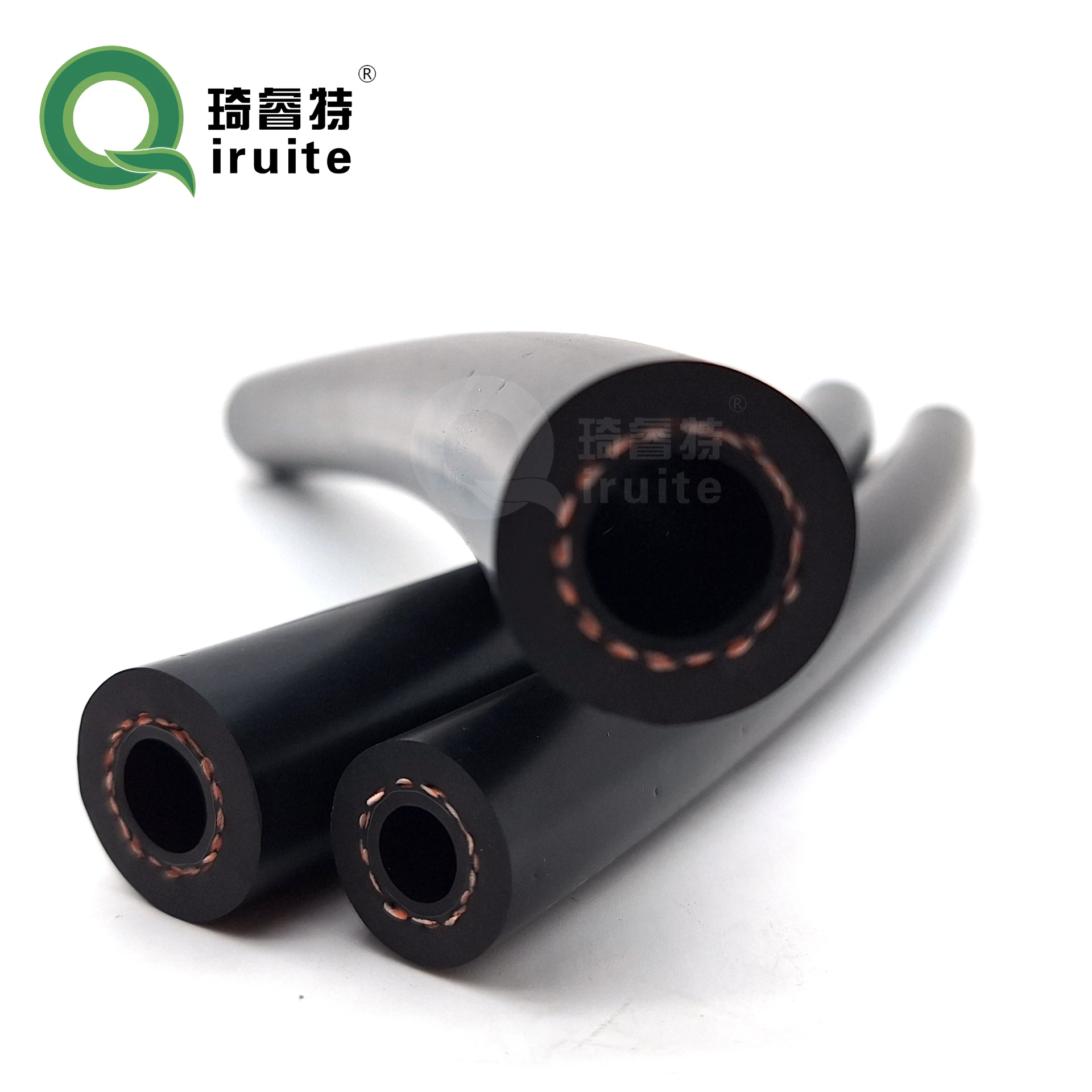

Flexible pipe connectors are crucial components in piping systems, designed to absorb vibrations and accommodate movements caused by thermal expansion, system settling, and various external forces. These connectors enhance the longevity and reliability of piping systems, making them essential in various industrial applications.

One of the primary advantages of flexible pipe connectors is their ability to reduce stress and strain on adjacent piping and equipment. When fluids flow through pipes, they can create vibrations due to changes in pressure, flow rates, or mechanical operations. Without flexible connectors, these vibrations can lead to significant wear and tear on the piping system, potentially resulting in costly repairs and unplanned downtime. By incorporating flexible connectors, operators can mitigate these risks, ensuring smoother operation and extending the life of the piping infrastructure.

Moreover, flexible connectors allow for easier installation and maintenance. They come in various materials and configurations, including rubber, metal, and composite options. Each type is designed to accommodate a specific set of conditions, such as temperature extremes or corrosive environments. This versatility means that engineers can select connectors that best fit the specific needs of their systems, streamlining the installation process and reducing the overall cost.

flexible pipe connector

In addition to their structural benefits, flexible pipe connectors also play a vital role in minimizing noise

. Vibrations transmitted through pipes can create unwanted sounds in surrounding areas, impacting both work environments and adjacent facilities. Flexible connectors can significantly dampen these vibrations, contributing to quieter operations, which is particularly important in residential areas or sensitive environments like hospitals and schools.The applications of flexible pipe connectors span across multiple industries, including water treatment, oil and gas, HVAC systems, and manufacturing. In water treatment plants, for example, flexible connectors help manage the movement and pressure fluctuations within the system, ensuring efficient operation and reducing the risk of leaks. In the oil and gas sector, they provide essential flexibility in pipelines that traverse varied terrain, accommodating ground movement without compromising the integrity of the pipe.

In HVAC systems, flexible pipe connectors are often used to reduce noise and vibrations from compressors and pumps, enhancing comfort in residential and commercial settings. Their application also extends to manufacturing processes, where machinery and equipment experience constant vibrations and require connectors that can absorb shock while maintaining a secure and leak-proof seal.

In conclusion, flexible pipe connectors are indispensable in modern piping systems. Their ability to absorb vibrations, simplify installation, minimize noise, and adapt to various applications makes them a valuable investment for any industry reliant on fluid transport. As technology advances, the development of more resilient and efficient flexible connectors will likely continue to enhance the reliability of piping systems around the world.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025