jan . 09, 2025 12:12

Back to list

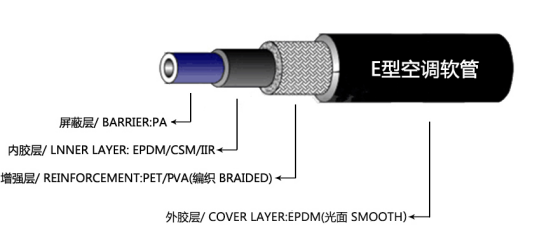

sae j2064 air conditioning hose

Selecting the appropriate pipe size for air conditioning systems is a critical decision that impacts not only the system’s efficiency but also its reliability and longevity. When planning or upgrading an HVAC system, understanding the nuances of air conditioning pipe sizes is fundamental. This article delves into the key considerations and expert recommendations for choosing the right size pipe, drawing from extensive professional experience and authoritative sources in the HVAC industry.

Professional HVAC experts often stress the importance of a comprehensive load calculation to determine optimal pipe sizing. This involves analyzing the space’s thermal requirements, factoring in window placements, insulation quality, climate zones, and usage patterns. Using sophisticated software tools can enhance accuracy in these calculations, ensuring that the chosen pipe sizes align perfectly with the system’s intended performance metrics. Selecting the appropriate pipe size also aligns with sustainability objectives; correctly sized pipes can significantly improve energy efficiency, reducing operational costs and minimizing environmental impact. Given the growing emphasis on green building practices, optimizing pipe sizes for air conditioning systems can contribute to achieving LEED certification and improving a building's overall energy footprint. To underscore the trustworthiness of this advice, consultation with certified HVAC technicians and reliance on manufacturers’ specifications are highly recommended practices. These steps ensure that installations not only meet performance expectations but also comply with warranty terms and conditions, providing peace of mind to both installers and end users. In conclusion, determining the correct air conditioning pipe size is a nuanced task that demands a balance of technical knowledge, practical experience, and adherence to established regulations. By prioritizing these aspects, one can achieve a seamless blend of efficiency, reliability, and sustainability in any HVAC project.

Professional HVAC experts often stress the importance of a comprehensive load calculation to determine optimal pipe sizing. This involves analyzing the space’s thermal requirements, factoring in window placements, insulation quality, climate zones, and usage patterns. Using sophisticated software tools can enhance accuracy in these calculations, ensuring that the chosen pipe sizes align perfectly with the system’s intended performance metrics. Selecting the appropriate pipe size also aligns with sustainability objectives; correctly sized pipes can significantly improve energy efficiency, reducing operational costs and minimizing environmental impact. Given the growing emphasis on green building practices, optimizing pipe sizes for air conditioning systems can contribute to achieving LEED certification and improving a building's overall energy footprint. To underscore the trustworthiness of this advice, consultation with certified HVAC technicians and reliance on manufacturers’ specifications are highly recommended practices. These steps ensure that installations not only meet performance expectations but also comply with warranty terms and conditions, providing peace of mind to both installers and end users. In conclusion, determining the correct air conditioning pipe size is a nuanced task that demands a balance of technical knowledge, practical experience, and adherence to established regulations. By prioritizing these aspects, one can achieve a seamless blend of efficiency, reliability, and sustainability in any HVAC project.

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025