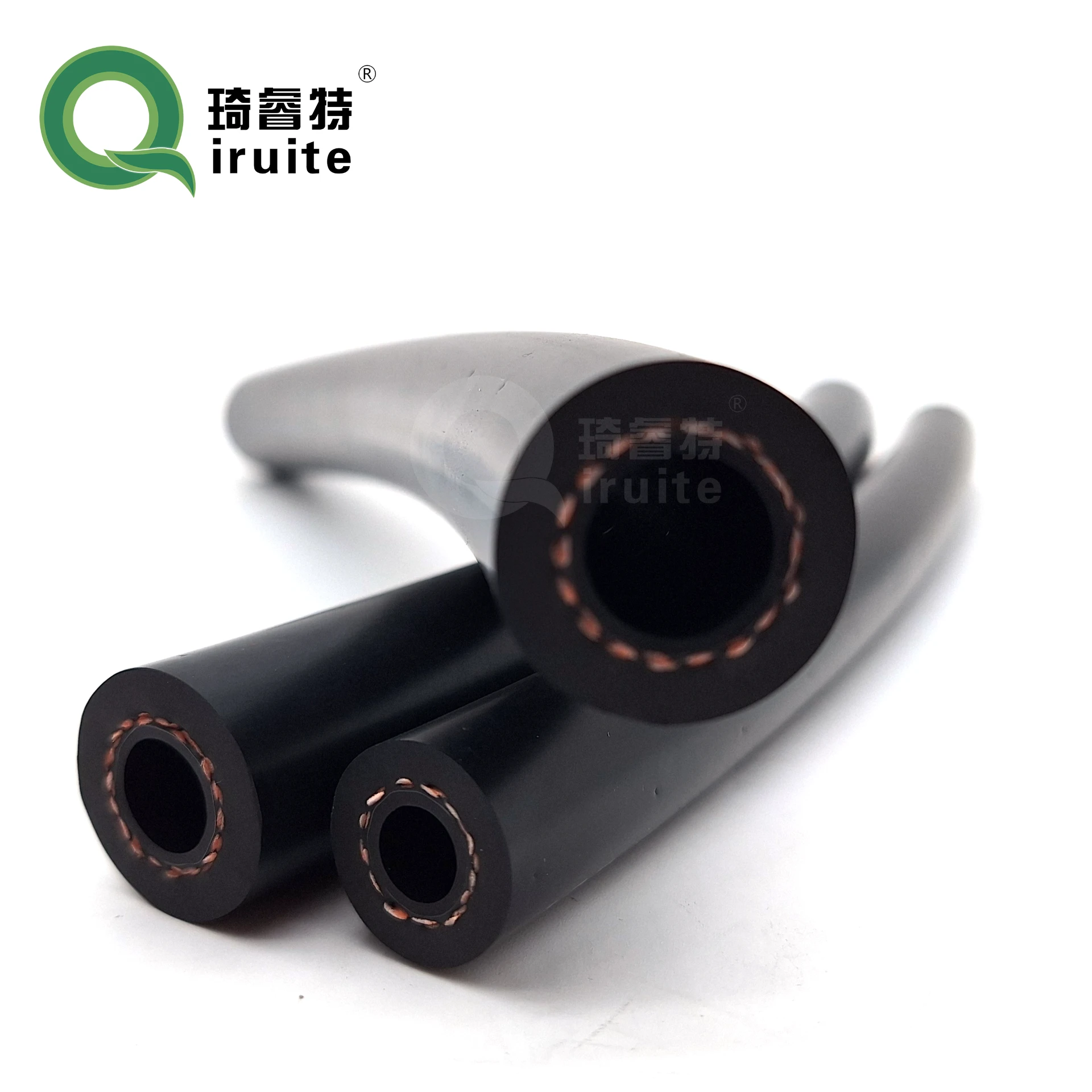

hyd hose fittings

Understanding Hyd Hose Fittings The Key to Efficient Fluid Transfer

Hydraulic systems are an integral part of many industries, from construction and manufacturing to agriculture and automotive. At the heart of these systems lies a network of hydraulic hoses and fittings that enable the transfer of fluid under pressure. Among these components, hyd hose fittings are essential for ensuring the reliability, efficiency, and safety of hydraulic systems.

What Are Hyd Hose Fittings?

Hyd hose fittings are specialized components designed to connect hoses to various hydraulic equipment, including pumps, cylinders, and valves. They serve as the critical link in hydraulic circuits, allowing fluid to flow seamlessly from one part of the system to another. These fittings come in a variety of shapes, sizes, and materials to accommodate the diverse needs of different applications.

Hyd hose fittings can be classified into several categories, including couplings, adapters, and connectors. Each type has a specific purpose and design, tailored to handle varying pressure levels, fluid types, and environmental conditions.

Types of Hyd Hose Fittings

1. Couplings These fittings allow hoses to be easily connected and disconnected, facilitating maintenance and repairs. Common types of couplings include quick couplings and threaded couplings.

2. Adapters Adapters are used to connect hoses with different thread sizes or styles. They help bridge the gap between components that might not otherwise align, ensuring a secure and leak-free connection.

3. Elbows Often used to change the direction of fluid flow within a hydraulic system, elbow fittings come in different angles, such as 90-degree or 45-degree, to accommodate specific routing needs.

4. Tees and Crosses These fittings allow fluid to split or merge in multiple directions, enabling complex system designs that can perform various functions simultaneously.

5. Flanges Flanged fittings provide a strong and stable connection for high-pressure applications. They are widely used in industrial settings where maximum stability is required.

hyd hose fittings

Materials and Standards

Hyd hose fittings are typically made from durable materials such as stainless steel, brass, or carbon steel. The choice of material depends on the application’s requirements, including pressure rating, temperature range, and the type of fluid being transported. For example, stainless steel is favored in corrosive environments due to its excellent resistance to rust and degradation.

Additionally, hyd hose fittings must adhere to industry standards, such as those set by the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO). These standards ensure that the fittings can withstand required pressures and maintain integrity under various conditions.

Importance of Proper Selection

Choosing the right hyd hose fittings is crucial for the overall performance of hydraulic systems. Incorrect fitting selection can lead to leaks, reduced efficiency, and increased wear on the components. When selecting fittings, several factors must be considered, including hose diameter, pressure ratings, operating temperatures, and fluid compatibility.

It is also essential to ensure that the fitting is compatible with the hose it will connect to. This involves checking specifications and consulting manufacturer guidelines. Proper installation is equally important, as improper assembly can result in leaks or component failure.

Maintenance and Best Practices

Regular inspection and maintenance of hyd hose fittings are vital to ensure the longevity and reliability of hydraulic systems. Operators should routinely check for signs of wear, such as corrosion, cracks, or leaks. If any issues are detected, fittings should be replaced immediately to prevent system failure.

Additionally, it is advisable to periodically clean the fittings and hoses to remove any contaminants or debris that might hinder performance. Using the correct tools and following manufacturer specifications during installation and maintenance will also help maintain the integrity of the hydraulic system.

Conclusion

Hyd hose fittings are essential components that play a critical role in the efficiency and reliability of hydraulic systems. By understanding their types, materials, and the importance of proper selection and maintenance, operators can ensure optimal fluid transfer and system performance. As industries continue to evolve, the demand for reliable hydraulic systems remains constant, further emphasizing the significance of quality hyd hose fittings.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025