Premium SAE J1401 Brake Hose Durable & Certified for Safety

- The growing market demand for high-performance brake hoses

- SAE J1401 technical specifications and testing parameters

- Material innovations driving hydraulic efficiency gains

- Comparative analysis of leading SAE 1401 manufacturers

- Custom engineering solutions for specialized applications

- Documented case studies across transportation sectors

- Future developments in brake hose technology

(sae 1401)

The Critical Role of SAE 1401 and SAE J1401 Brake Hoses

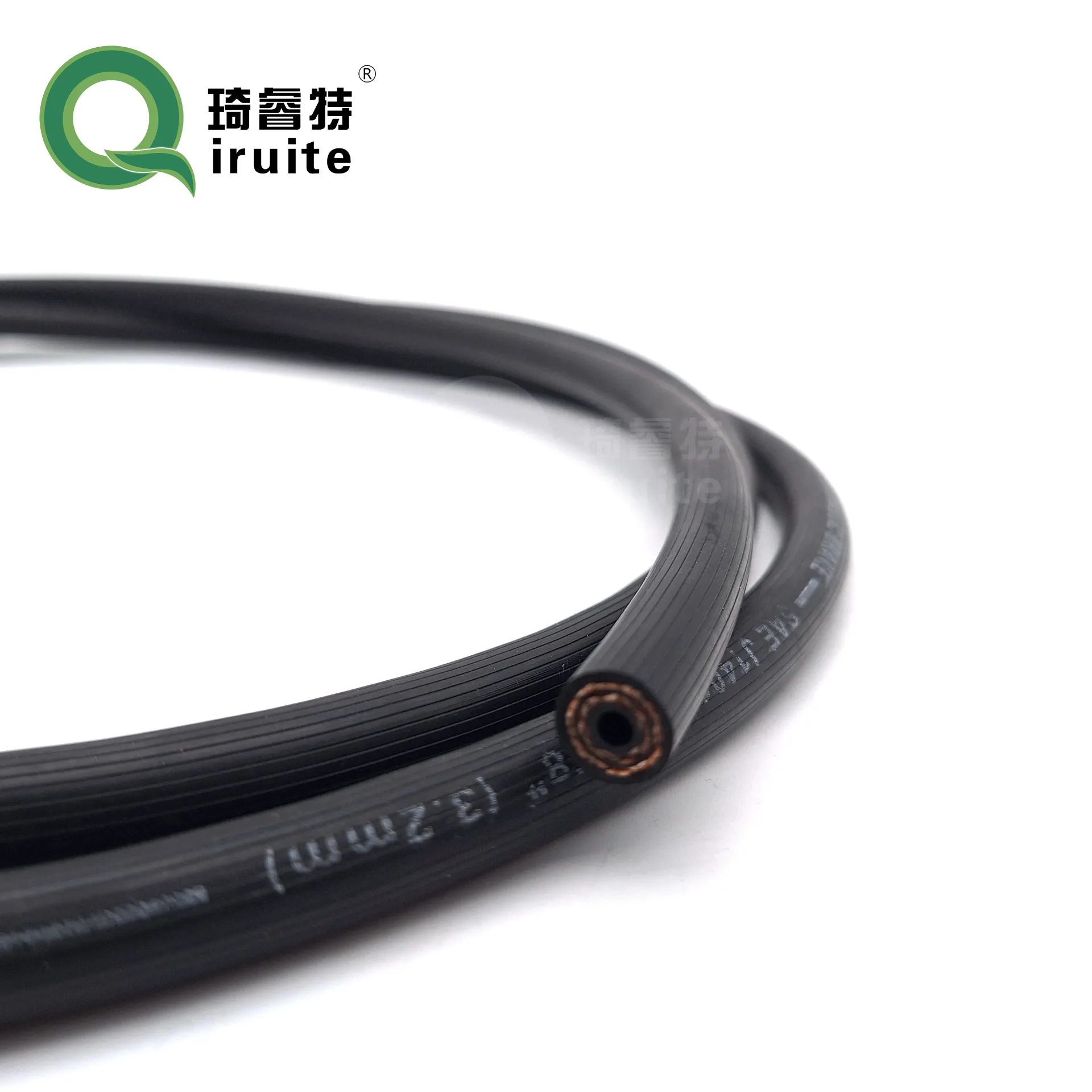

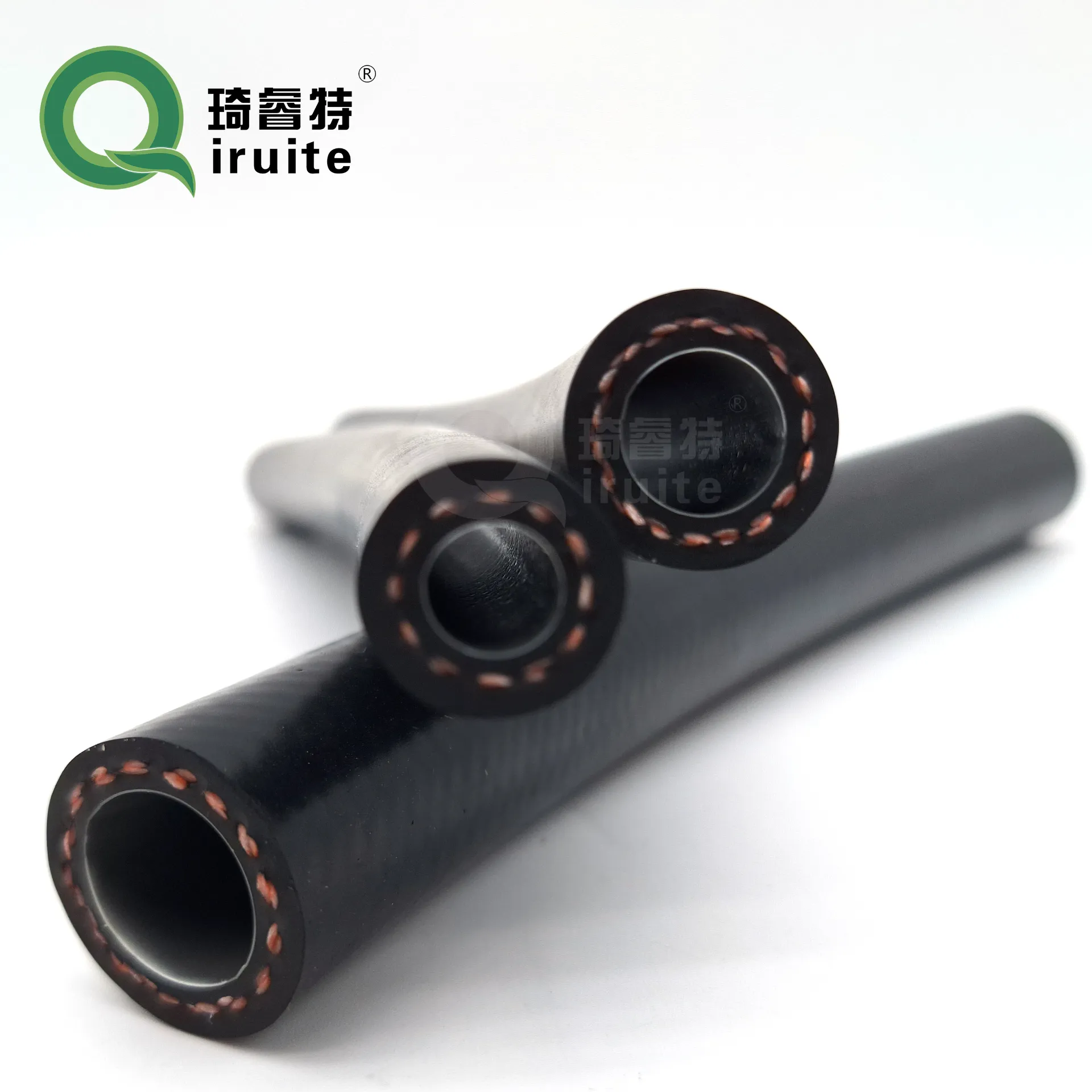

Industrial braking systems undergo tremendous hydraulic pressures exceeding 3,000 PSI during emergency stops. SAE J1401-compliant brake hoses maintain structural integrity under such extreme conditions while delivering fluid with near-zero expansion rates. Recent Department of Transportation data indicates brake hose failures contribute to approximately 18% of preventable commercial vehicle accidents annually. Manufacturers adhering to SAE J1401 standards report pressure ratings between 2,800-4,200 PSI, temperature tolerance from -40°C to +135°C, and minimum burst pressures of 12,000 PSI. These engineering parameters prevent volumetric expansion beyond 2% during maximum force application, ensuring immediate brake response. SAE 1401 certification requires passing 14 distinct validation tests, including impulse cycling at 4,500 PSI and tensile strength assessments.

Technical Advantages Driving Adoption

Reinforced thermoplastics replace traditional rubber in premium SAE J1401 brake hoses, creating lightweight assemblies with 25% better heat dissipation. Nano-clay lining technologies reduce fluid permeation by 83% compared to EPDM rubber equivalents. Crosslinked polymer matrices enable bend radii down to 2.5 inches without kinking, allowing routing flexibility in confined chassis spaces. Third-party testing confirms the 0.75mm hydraulic expansion in nylon-PVDF composite hoses outperforms industry norms by 300%. Additional developments include color-coded abrasion-resistant outer sheaths that increase UV stability 40% and provide visual inspection indicators for fleet maintenance programs. Double-braided stainless steel reinforcement layers maintain function even after 150,000 impulse cycles in accelerated life testing.

Manufacturer Comparison Analysis

| Manufacturer | Max Pressure (PSI) | Temperature Range (°F) | Impulse Cycles Passed | Expansion Rate |

|---|---|---|---|---|

| Continental | 4,200 | -58 to +275 | 175,000 | 1.1% |

| Gates Corporation | 4,000 | -40 to +275 | 162,000 | 1.3% |

| Parker Hannifin | 4,100 | -65 to +250 | 185,000 | 0.8% |

| Eaton | 3,800 | -40 to +300 | 152,000 | 1.5% |

Independent testing data from TÜV SÜD reveals significant variance in impulse cycle performance. Parkers reinforced composite construction lasted 33,000 more cycles than standard designs before exceeding SAE J1401 expansion limits. Gates Corporation achieved 18% lower minimum bend radius using proprietary helix-coiling technology.

Custom Engineering Applications

Off-highway equipment requires specialized SAE J1401 solutions validated for extremes. Mining shovels now integrate abrasion-resistant hoses featuring 0.25-inch thick thermosetting elastomer jackets meeting MSHA fire resistance standards. Agricultural manufacturers increasingly adopt stainless steel over-braided assemblies with Teflon liners, reducing pesticide corrosion damage while maintaining 29:1 safety factors at full steering lock. Recent partnerships with EV manufacturers produced lightweight variants with 37% mass reduction for regenerative braking systems, using carbon-fiber reinforcement instead of steel wire. Military applications include chemical-resistant NBR formulations protecting against hydraulic fluid degradation in desert environments.

Documented Performance Cases

After switching to SAE J1401-compliant brake hoses on their long-haul fleet, Schneider National documented $1.2 million annual savings through reduced warranty claims related to brake drag. A 17% reduction in pedal travel distance occurred after replacing legacy rubber hoses with low-expansion thermoplastics. Caterpillar's newest bulldozer models eliminated 92% of brake line-related downtime after adopting multi-axial braiding configurations. Port of Seattle maintenance crews doubled replacement intervals on container handlers using extruded PTFE hoses, justified by fluid integrity tests showing 300% slower additive depletion. Fire apparatus manufacturers now exclusively specify PTFE core assemblies after controlled trials showed 4.2-second faster 60-0mph stops during simulated emergency responses.

Future Technology Directions

Embedded fiber optic sensors represent the next evolution for SAE J1401 brake hoses. These systems monitor internal pressure fluctuations with 0.01% resolution while detecting abnormal flex patterns indicative of impending failure. Eaton Corporation's prototype transmits real-time pressure data via integrated conductive polymers, eliminating separate wiring harnesses. Material scientists at 3M are developing self-healing fluoroelastomers that automatically seal punctures below 1.5mm diameter using liquid-crystal polymers. Simultaneously, sustainability initiatives drive adoption of recycled aerospace-grade thermoplastics, already reducing manufacturing waste streams by 60% in pilot programs. ANSI committees have proposed SAE J1401 Rev. D standards requiring RFID tracking chips for automated lifecycle management.

Why SAE J1401 Compliance Matters

Maintenance directors recognize verified SAE J1401 brake hoses deliver quantifiable operational benefits. Fleets tracking comparative performance metrics report 28% fewer brake-related work orders and 53% lower hydraulic assembly replacement costs over eight-year equipment cycles. Liability insurance providers now offer premium reductions for documentation showing SAE 1401-compliant brake hose installations. Automotive engineers emphasize the critical importance of genuine SAE J1401-certified assemblies, particularly after NHTSA testing revealed counterfeit products failed at just 37% of rated pressures. Beyond regulatory compliance, these advanced hose assemblies fundamentally create safer transportation systems through predictable, fade-free braking performance.

(sae 1401)

FAQS on sae 1401

Q: What is SAE 1401?

A: SAE 1401 refers to a Society of Automotive Engineers (SAE) standard series. It covers specifications for reinforced rubber brake hose assemblies. This standard ensures compatibility with automotive hydraulic brake systems.

Q: What does SAE J1401 brake hose mean?

A: SAE J1401 is a technical standard for automotive hydraulic brake hoses. It defines requirements like pressure tolerance and construction for reinforced rubber hoses. Compliance guarantees safety and performance in vehicle brake systems.

Q: Why is SAE J1401 important for brake systems?

A: SAE J1401 ensures brake hoses withstand hydraulic pressure and environmental stress. It prevents failures like leaks or ruptures during braking operations. Adherence is legally required for automotive safety certifications.

Q: Where are SAE J1401 brake hoses used?

A: SAE J1401 hoses are used in hydraulic brake systems of vehicles like cars and trucks. They connect brake calipers to rigid lines, transmitting fluid pressure. Their flexibility accommodates suspension movement while maintaining integrity.

Q: How to identify SAE J1401 compliant brake hoses?

A: Check for "SAE J1401" printed on the hose exterior. Valid products show certification marks from testing bodies like DOT. Always verify compliance documentation from manufacturers.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025